Light emitting diode packaging structure and manufacturing method thereof

A technology of light-emitting diodes and packaging structures, applied in electrical components, electric solid devices, circuits, etc., can solve problems such as prolonging the life of unfavorable LED light sources, poor heat dissipation of LED light sources, and unfavorable heat dissipation of LED light sources, and achieves improved heat dissipation effect and good insulation. good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

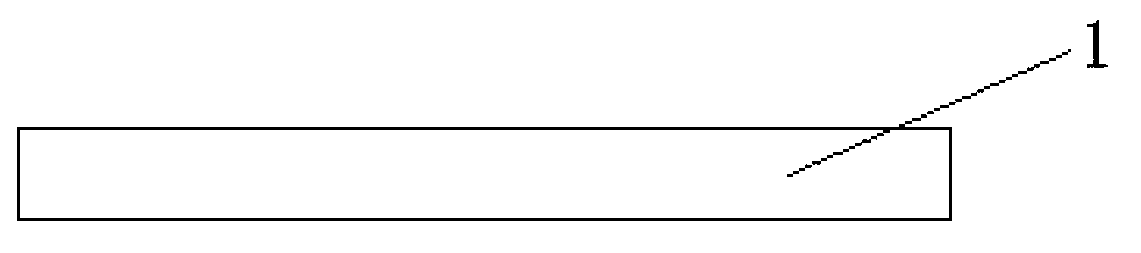

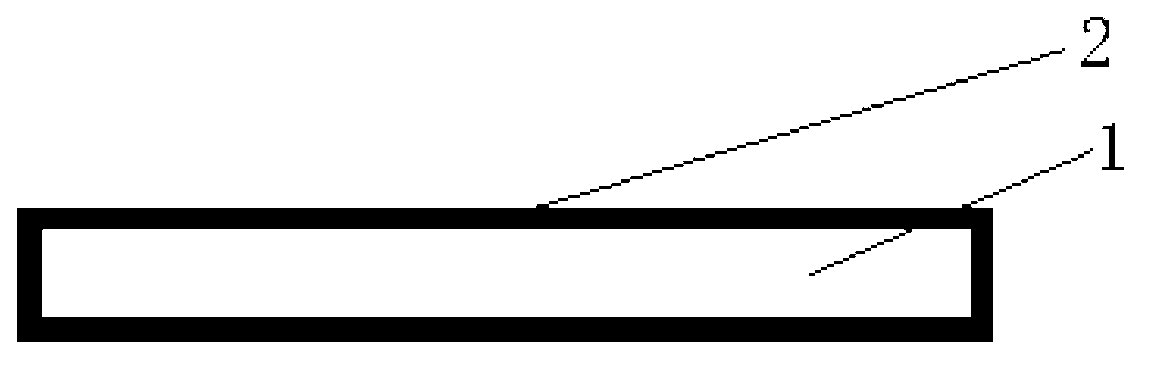

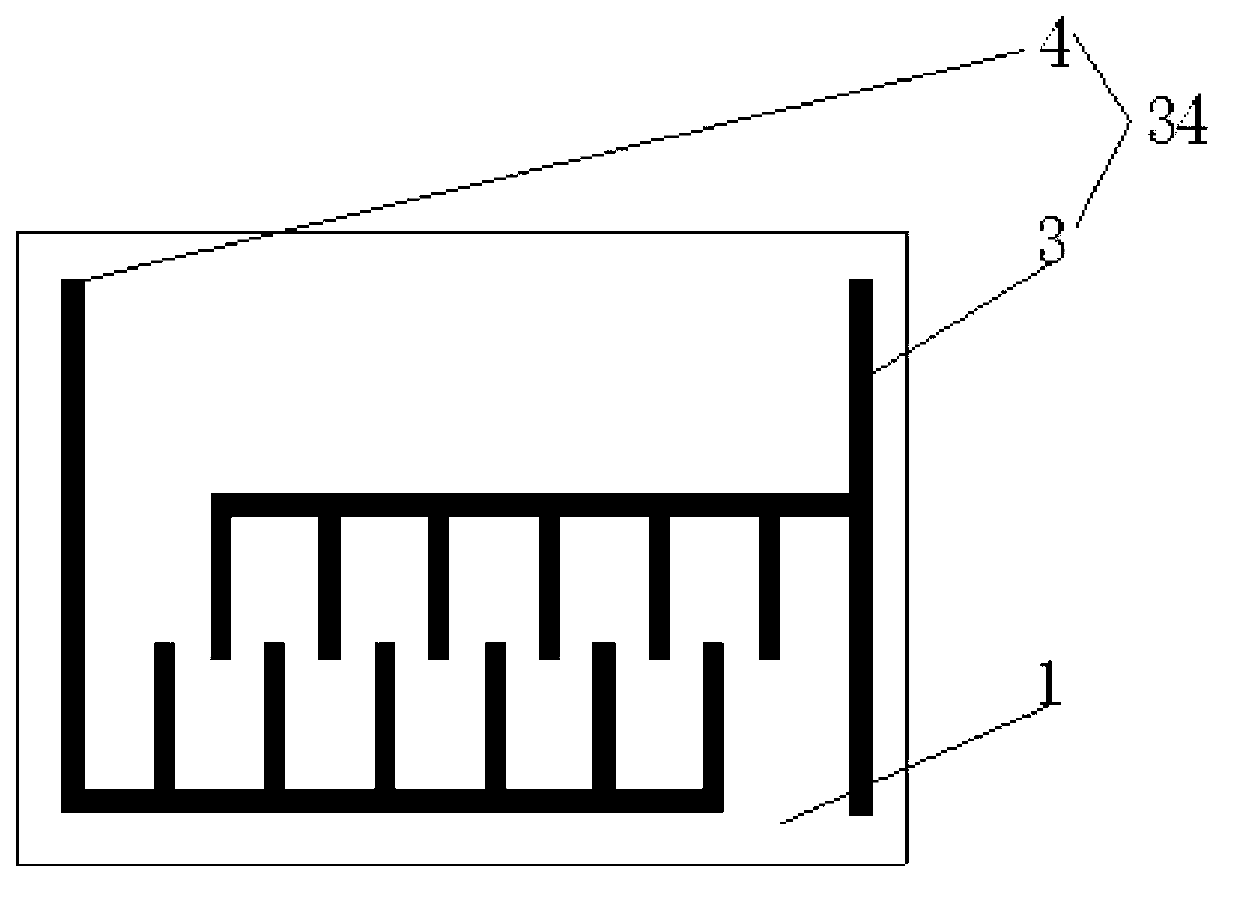

[0036] Such as Figure 1 to Figure 6 As shown, a light-emitting diode packaging structure provided by the present invention includes a transparent substrate 1, an LED chip 5 and a wire support 34, the wire support 34 is installed on the transparent substrate 1, the LED chip 5 is fixed on the transparent substrate, and the LED chip The electrodes of 5 are connected to the lead frame 34; the transparent substrate 1 is transparent glass or transparent sapphire substrate or transparent ceramic or organic transparent plastic.

[0037] Wherein, the light transmittance of the transparent substrate 1 is greater than 90%.

[0038] The single side, double side or three-dimensional surface of the transparent substrate 1 is evenly coated with a transparent high thermal conductivity film 2, and the required parameters of the transparent high thermal conductivity film 2 are: light transmittance greater than 90%, thermal conductivity greater than or equal to 400w / m·k; transparent The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com