Brushless DC variable frequency motor and control system using brushless DC variable frequency motor

A DC frequency conversion motor and control system technology, applied in the direction of motors, control drives, battery circuit devices, etc., can solve the problems of magnet offset, high motor power of brushless frequency conversion motors, and failure to achieve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

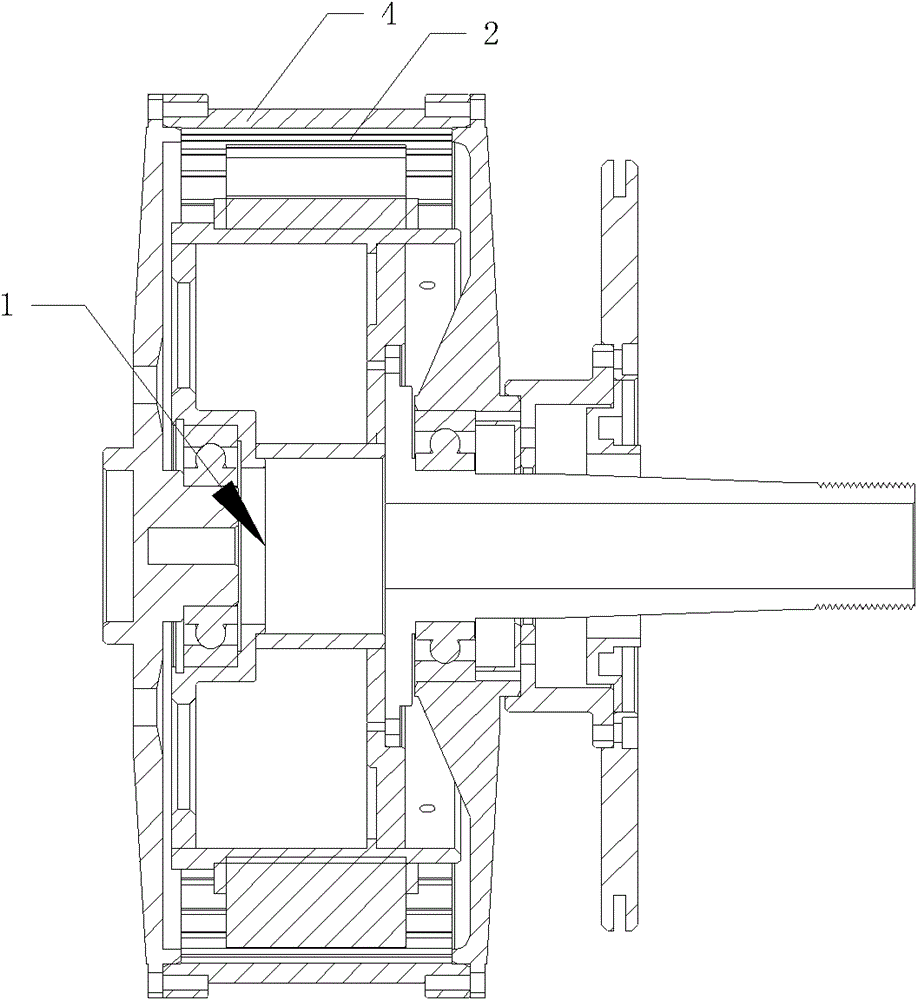

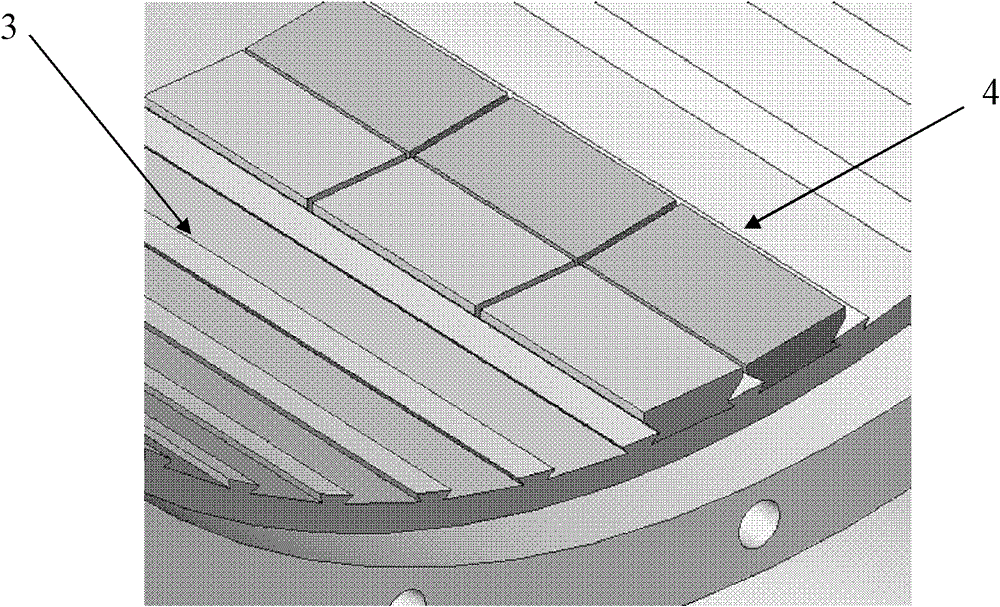

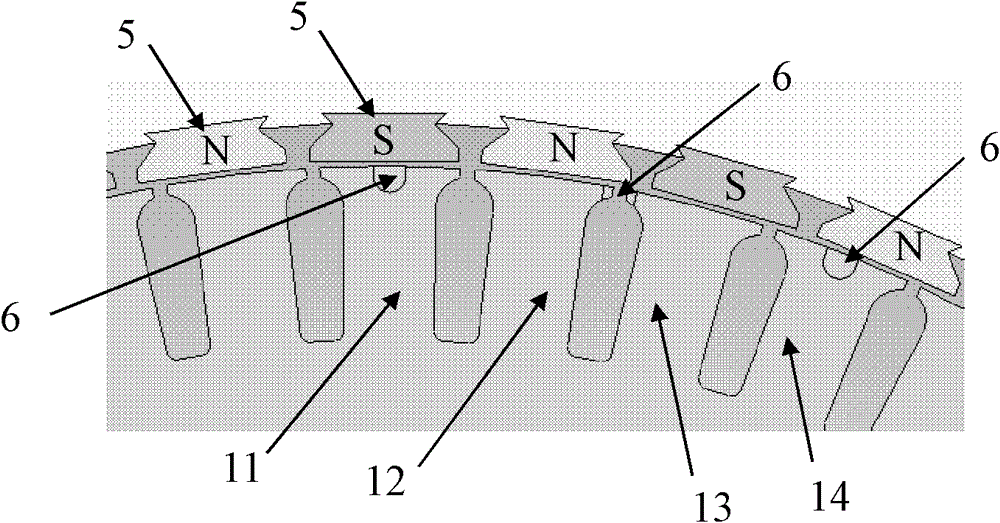

[0038] like figure 1 , figure 2 and image 3 As shown, the brushless DC frequency conversion motor shown in the present invention includes a stator 1 and a rotor 2 of an excitation winding, the inner surface of the rotor 2 is provided with a trapezoidal groove 3, and a NdFeB magnet 4 is installed in the trapezoidal groove 3 , just plug in from the port. The NdFeB magnet 4 is made of rich rare earth rubidium in my country, which is different from the permanent magnets used in brushed DC motors. The magnetism of the NdFeB magnets is stronger than that of the permanent magnets. Many, if you use "universal glue" to paste, it will be completely inoperable. At the same time, in the same trapezoidal groove 3, the arranged NdFeB magnets 4 are of the same sex, and at the same time, the same sex of the NdFeB magnets 4 arranged in another adjacent trapezoidal slot 3 are opposite to each other. Although the polarities of the NdFeB magnets 4 in the adjacent two rows of trapezoidal groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com