Metal porous membrane preparation method and device based on laser shock wave effect

A metal porous and shock wave technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as complex processes, achieve good toughness, avoid cracking, and avoid deceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

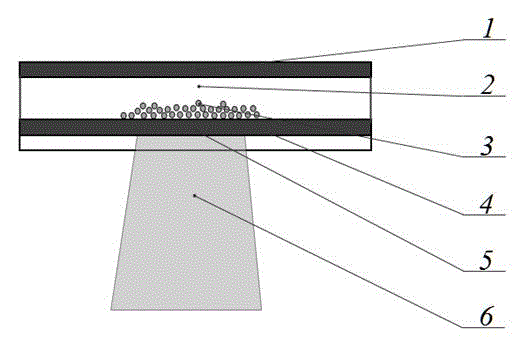

[0023] The metal film 1 described in this example is a stainless steel film with a thickness of 10 μm; the hard microparticle 3 is a SiC particle with a particle size of 10 nm; the absorption layer 4 is an aluminum foil with a thickness of 100 μm; the constrained layer 5 is K9 with a thickness of 3 mm. Optical glass; high-energy pulsed laser 6 is a pulsed laser with a pulse width of 10 ns and a maximum pulse energy of 12J.

[0024] Implement a kind of metal porous film preparation method based on laser shock wave effect of the present invention to carry out the following steps:

[0025] 1) Covering the absorbing layer 4 on the surface of the constraining layer 5;

[0026] 2) covering the surface of the absorbing layer 4 with a layer of hard microparticles 3 with a thickness of about 1 μm;

[0027] 3) placing the metal thin film 1 at a position about 2 mm above the absorbing layer 4;

[0028] 4) Place the whole device in the vacuum chamber 2;

[0029] 5) The high-energy puls...

Embodiment 2

[0033] The metal film 1 described in this example is a titanium film with a thickness of 50 μm; the hard microparticle 3 is a WC particle with a particle size of 0.2 μm; the absorption layer 4 is an aluminum foil with a thickness of 100 μm; K9 optical glass; high-energy pulse laser 6 is a pulse laser with a pulse width of 20ns and a maximum pulse energy of 12J.

[0034] Implement a kind of metal porous film preparation method based on laser shock wave effect of the present invention to carry out the following steps:

[0035] 1) Covering the absorbing layer 4 on the surface of the constraining layer 5;

[0036] 2) covering the surface of the absorbing layer 4 with a layer of hard microparticles 3 with a thickness of about 1 μm;

[0037] 3) placing the metal film 1 at a position about 5 mm above the absorbing layer 4;

[0038] 4) Place the whole device in the vacuum chamber 2;

[0039] 5) The high-energy pulsed laser 6 passes through the constrained layer 5 and irradiates on ...

Embodiment 3

[0043] The metal film 1 described in this example is a nickel film with a thickness of 100 μm; the hard microparticle 3 is a SiC particle with a particle size of 10 μm; the absorption layer 4 is an aluminum foil with a thickness of 100 μm; the constrained layer 5 is K9 with a thickness of 3 mm Optical glass; high-energy pulsed laser 6 is a pulsed laser with a pulse width of 30ns and a maximum pulse energy of 12J.

[0044] Implement a kind of metal porous film preparation method based on laser shock wave effect of the present invention to carry out the following steps:

[0045] 1) Covering the absorbing layer 4 on the surface of the constraining layer 5;

[0046] 2) covering the surface of the absorbing layer 4 with a layer of hard microparticles 3 with a thickness of about 1 μm;

[0047] 3) placing the metal thin film 1 at a position about 2 mm above the absorbing layer 4;

[0048] 4) Place the whole device in the vacuum chamber 2;

[0049] 5) The high-energy pulsed laser 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com