Moving bed bio-membrane reactor for aquaculture

A moving bed biofilm and aquaculture technology, applied in the field of moving bed biofilm reactors for aquaculture, can solve the problems of water treatment efficiency to be further improved, water distribution, aeration is not easy to be uniform, large floor area, etc., to achieve The effect of reducing sludge production, promoting the exponential growth of microbial populations, and enriching dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

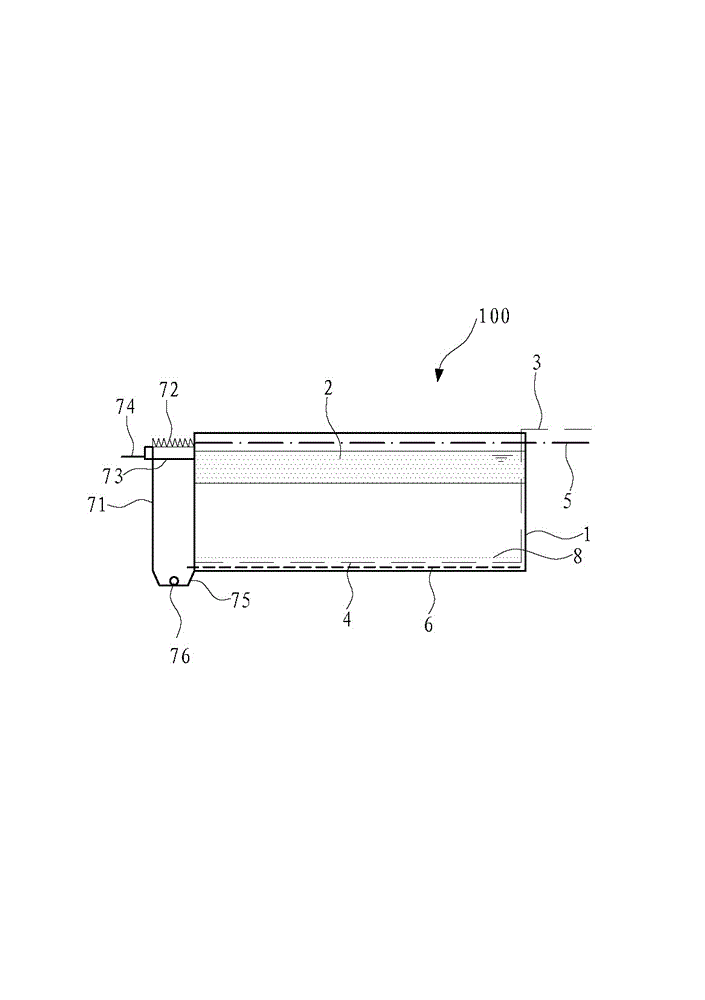

[0030] like figure 1 As shown, a moving bed biofilm reactor 100 for aquaculture that the present invention relates to includes a reaction tank 1, a hydrophilic suspended filler 2, an air pump, an air inlet pipe 3, an aeration pipe 4, an inlet pipe 5 and a drain pipe 6.

[0031] The specific surface area of the suspended filler 2 is greater than 600 m 2 / m 3 , the filling rate of the suspension filler 2 is 27% to 30% of the effective volume of the reaction tank 1; further, the suspension filler 2 is ring-shaped and made of polyethylene material, and the specific gravity of the suspension filler 2 is 0.94g / cm 3 . In this way, microorganisms are easy to attach and gather on the surface of the suspended filler 2 to form a large amount of biofilm (biofilm film-hanging mature technology can adopt conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com