Semi-rebonded magnesite-chrome brick for copper smelter and preparation method thereof

A semi-recombination, copper smelting furnace technology, applied in the field of lining materials for copper smelting furnaces and their preparation, can solve the problems of poor thermal shock stability, weak corrosion resistance, easy deformation of brick bodies, etc. Thermal shock stability, excellent slag corrosion resistance, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

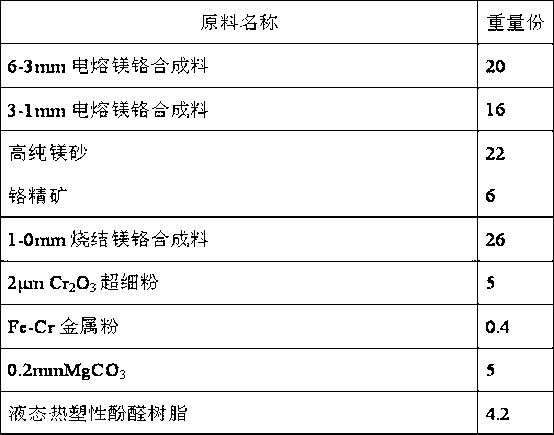

[0020] Raw materials for semi-rebonded magnesia-chrome bricks for copper smelting furnaces are shown in Table 1:

[0021] Table 1 Raw materials contained in semi-rebonded magnesia-chrome bricks for copper smelting furnaces

[0022]

[0023] The manufacturing method of the semi-recombined magnesia-chrome brick for copper smelting comprises the following steps:

[0024] 1) According to the weight parts of high-purity magnesia and chrome concentrate described in Table 1, weigh them and put them into a ball mill for co-grinding until the particle size is less than 0.088mm, accounting for more than 95%;

[0025] 2) Ingredients: Fused magnesia-chromium synthetic material, co-grinding material of high-purity magnesia and chrome concentrate, sintered magnesia-chromium synthetic material, Cr 2 o 3 Superfine powder, metal admixture and additives are weighed according to the weight fraction and poured into the mixer mill, first dry mixed for 3-5 minutes and mixed evenly, then added ...

Embodiment 2

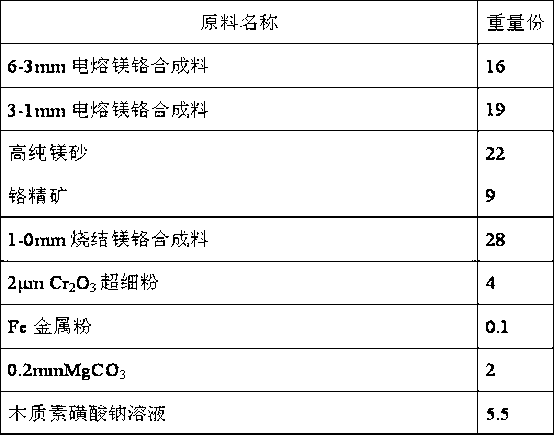

[0031] The raw materials contained in semi-recombined magnesia-chrome bricks for copper smelting are shown in Table 2:

[0032] Table 2 Raw materials contained in semi-rebonded magnesia-chrome bricks for copper smelting furnaces

[0033]

[0034] In this example, semi-rebonded magnesia-chrome bricks for copper smelting are prepared, the sintering temperature is 1700° C., the holding time is 4 hours, and the rest of the steps are the same as in Example 1.

Embodiment 3

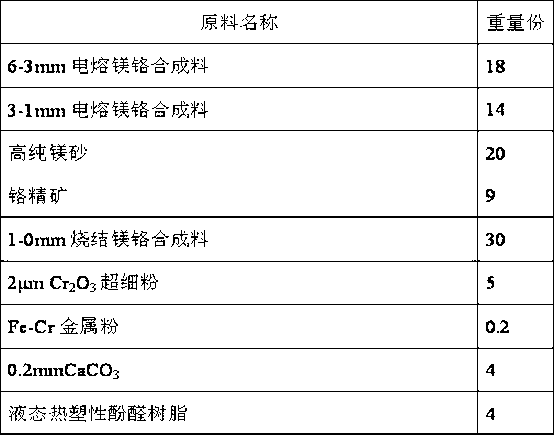

[0036] The raw materials contained in the semi-recombined magnesia-chrome bricks for copper smelting furnace are shown in Table 3:

[0037] Table 3 Raw materials contained in semi-rebonded magnesia-chrome bricks for copper smelting furnaces

[0038]

[0039] In this example, semi-rebonded magnesia-chrome bricks for copper smelting furnaces were prepared, the sintering temperature was 1750° C., the holding time was 4.5 hours, and the rest of the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com