Preparation method and application off dyeing promoter

A dyeing accelerator and reaction technology are applied in the field of preparation of polyepichlorohydrin amide dyeing accelerators to achieve the effects of shortened dyeing process flow, reduced residual amount and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

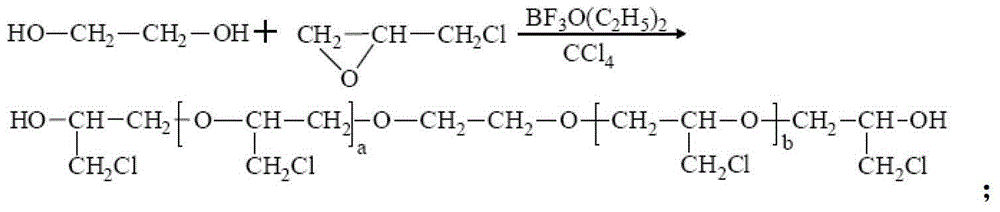

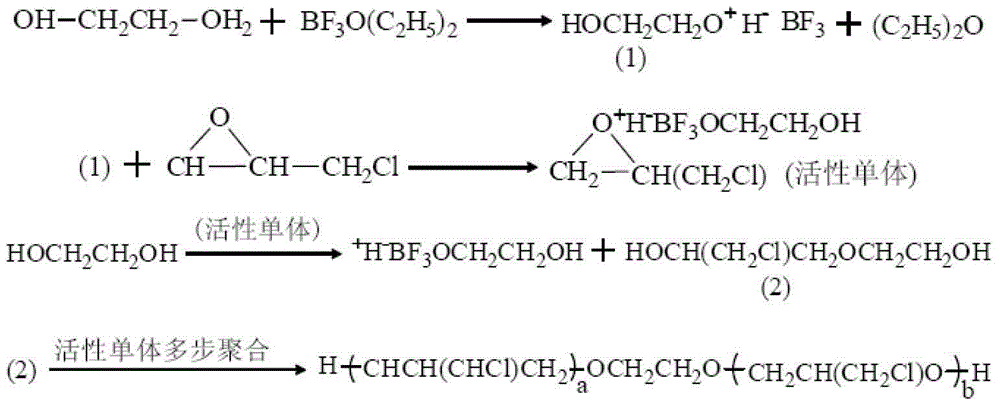

[0043] The method for preparing dyeing accelerator DL-71

[0044] Connect a constant pressure funnel, a nitrogen inlet, a thermometer, and a stirring device to the four-necked flask, and pass nitrogen to remove the air in the device; place the entire device in an ice-water bath at 0-5°C, and add 80ml of CCl in sequence 4 , 11.35gBF 3 O(C 2 h 5 ) 2 and 3.72gEG. Add 92.52g ECH into the constant pressure funnel, control the dropping rate to 1 drop / 2.5 seconds, and control the temperature at 32°C for 8 hours after the dropping is completed. Purify with 85:15 acetone-ethanol mixture after the reaction, and then add 10% EDTANa after purification 4 The low-molecular oligomers in the product were removed by an aqueous alcohol solution, and finally unreacted monomers and solvents were removed on a rotary evaporator at 60°C to obtain polyepichlorohydrin.

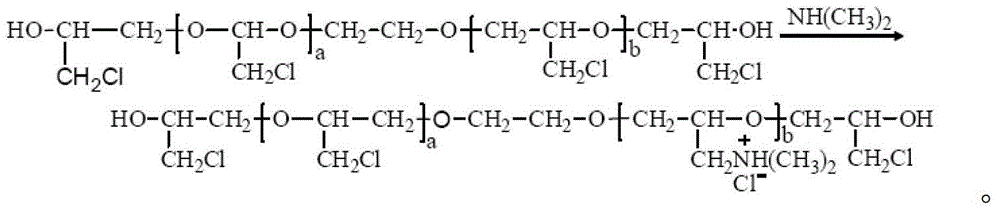

[0045] Weigh the polyepichlorohydrin and dimethylamine aqueous solution synthesized in the first step according to the mass ra...

Embodiment 2

[0047] Preparation method of dyeing accelerator DL-71

[0048] Connect the four-neck flask to a constant pressure funnel, a nitrogen inlet, a thermometer, and a stirring device, and pass nitrogen to remove the air in the device. Place the whole device in an ice-water bath at 0-5°C, and add 75ml of CCl in sequence 4 , 9.93gBF 3 O(C 2 h 5 ) 2 and 3.1gEG. Add 92.52g of ECH to the constant pressure funnel, control the dropping rate of 1 drop / 2 seconds, control the temperature at 30°C for 8 hours after the dropping is completed; after the reaction is completed, use 85:15 acetone-ethanol mixture to purify, and then add 10% EDTANa 4 The low-molecular oligomers in the product were removed by an aqueous alcohol solution, and finally unreacted monomers and solvents were removed on a rotary evaporator at 62°C to obtain polyepichlorohydrin.

[0049] Weigh the polyepichlorohydrin and dimethylamine aqueous solution synthesized in the first step according to the mass ratio of 1:3, pla...

Embodiment 3

[0051] Preparation method of dyeing accelerator DL-71

[0052] Connect the four-neck flask to a constant pressure funnel, a nitrogen inlet, a thermometer, and a stirring device, and pass nitrogen to remove the air in the device. Place the whole device in an ice-water bath at 0-5°C, and add 85ml of CCl in sequence 4 , 12.77gBF 3 O(C 2 h 5 ) 2 and 4.43g EG; add 92.52g ECH into the constant pressure funnel, control the dropping rate to 1 drop / 3 seconds, and control the temperature at 30°C for 10 hours after the dropping is completed. After the completion of the reaction, the acetone-ethanol mixture of 85:15 was purified, and after purification, it was purified by adding 12% EDTANa 4 The low-molecular oligomers in the product were removed by an aqueous alcohol solution, and finally unreacted monomers and solvents were removed on a rotary evaporator at 62°C to obtain polyepichlorohydrin.

[0053] Weigh the polyepichlorohydrin and dimethylamine aqueous solution synthesized in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com