Packing tower type continuous surface fermentation apparatus and implementation method thereof

The technology of fermentation device and packed tower is applied in the field of continuous surface fermentation device of packed tower type, which can solve the problems of large fermentation power consumption, low acid production capacity, long fermentation time, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

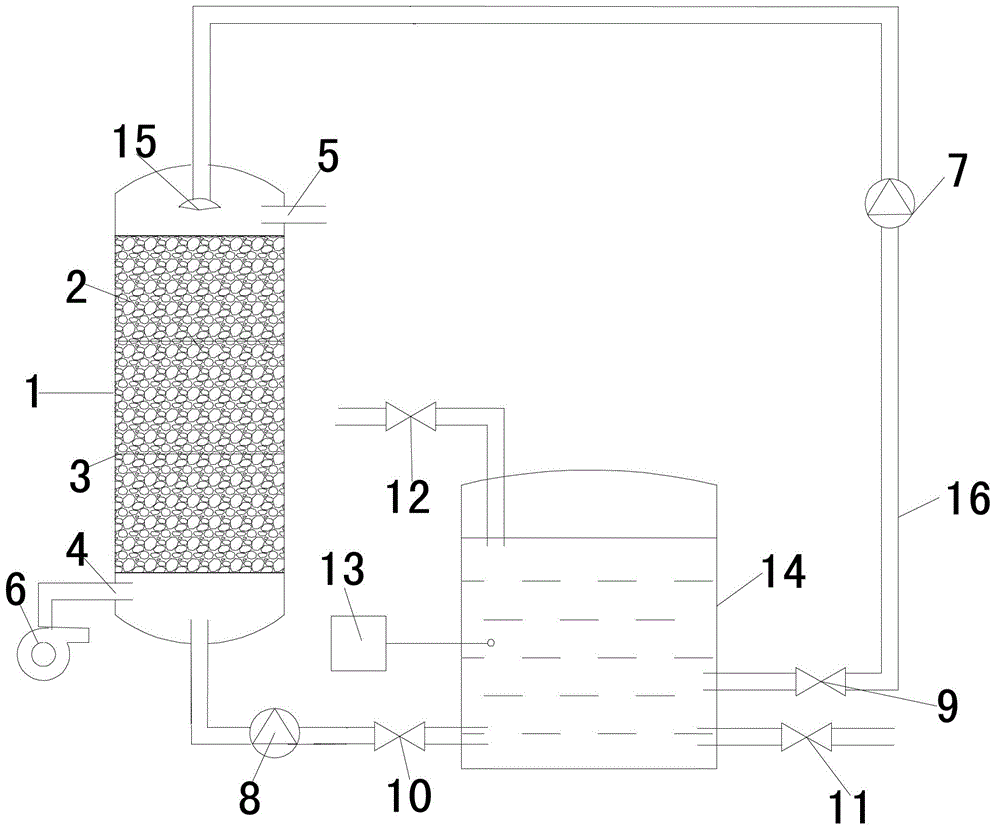

[0034] like figure 1 As shown, a packed tower type continuous surface fermentation device includes a packed tower 1, a packing material 2, several partitions 3, an air inlet 4, an air outlet 5, a fan 6, a first circulation pump 7, a second circulation pump 8, Feed valve 9, discharge valve 10, outlet valve 11, inlet valve 12, on-line acidity detector 13 and collection tank 14; wherein, the top of packed tower 1 is connected with collection tank 14 through circulation pipe 16, and the first circulation pump 7 to provide power, the circulation pipe 16 is provided with a feed valve 9, the fermentation liquid enters the packed tower 1 through the top of the packed tower 1, and several partitions 3 divide the packed tower 1 into several fermentation areas, and the filling Material 2, the fermentation liquid flows through the bacterial fiber membrane attached to the filling material 2 and ferments there, the upper side of the packed tower 1 is equipped with an air outlet 5, and the l...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that the filling material 2 in this embodiment is porous ceramics with a porosity of 50% and a bulk density of 800kg / m 3 In the present embodiment, the sugar content of the concentrated apple juice is adjusted to 12Brix, and after sterilization and cooling, 0.3% of activated fruit wine yeast and about 10% of Gluconacetobacter xylinus (Gluconacetobacter xylinus) RF4 strain liquid are inserted at the same time, and the apple juice fermented liquid is extracted from Import in the collection tank 14, close the inlet valve 12, then open the feed valve 9, and start the first circulation pump 7, the fermented liquid is pumped into the packed tower 1 through the circulating pipe 16, and the bacterial fiber film produced by Acetobacter xylinum in the fermented liquid will adhere to the filling material 2. The acidity is monitored online, and when the acidity detected by the online acidity detector 13 remains unchanged, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com