Processing method for sweet potato sheet jelly, and apparatus thereof

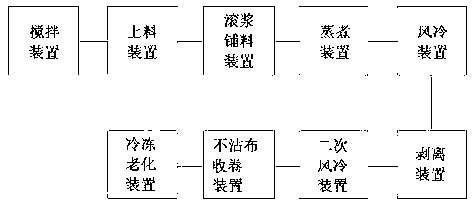

A processing method and technology of sweet potato flour, applied in the field of equipment for realizing the processing method of sweet potato vermicelli, can solve problems such as rough surface of vermicelli, unfavorable aging, short freezing time, etc., and achieve increased toughness and smoothness, improved swelling degree, and shape crystal clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

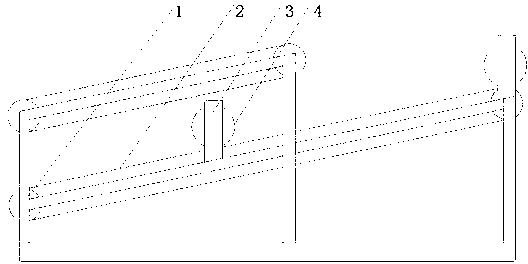

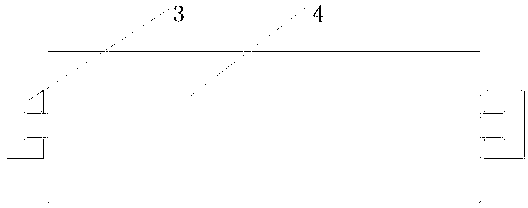

Method used

Image

Examples

Embodiment 1

[0034] The steps of the sweet potato vermicelli processing method:

[0035] a. Starch Physalis Purification: Stir for the first time to settle, add half of the capacity of the mixer to the mixer, start the mixer and add the raw starch while stirring, adjust the concentration of the starch slurry to 10 degrees after stirring evenly (sag hydrometer), add Physalis water to adjust the pH value to 5.6, let it stand for half an hour, remove the upper clear swill, protein, and fiber; then carry out the second stirring and sedimentation, that is, after the first stirring and sedimentation, add water to the starch and continue to stir, and then put the slurry through Remove the sand with the swirl sand remover, filter through a 100-mesh filter cloth, let the starch settle for 10 hours until the starch is completely precipitated, and skim the upper layer of acid slurry for mixing; then carry out the third stirring and precipitation, and the above acid The starch after the slurry is tran...

Embodiment 2

[0052] The steps of the sweet potato vermicelli processing method:

[0053] a. Starch Physalis Purification: Stir for the first time to settle, add half of the capacity of the mixer to the mixer, start the mixer and add the raw starch while stirring, adjust the concentration of the starch slurry to 15 degrees after stirring evenly (sag hydrometer), add Physalis water is adjusted to PH value to 5.6, and it is allowed to settle for half an hour to remove the upper clear swill, protein, and fiber; then carry out the second stirring and sedimentation, that is, after the first stirring and sedimentation, add water to the starch and continue to stir, and then put the powder slurry through Remove the sand with the swirl sand remover, filter through a 100-mesh filter cloth, let it settle for 20 hours until the starch is completely precipitated, and skim off the upper layer of acid slurry for mixing; The starch after the slurry is transferred to the mixer, added with water and stirred,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com