Ultra-precise static-pressure main shaft dynamic characteristic online testing method capable of eliminating measuring basis installation error

A static pressure spindle and measurement datum technology, which is applied in the direction of measuring/indicating equipment, machine gear/transmission mechanism testing, metal processing machinery parts, etc., can solve the influence of measurement datum surface installation accuracy measurement results, and cannot realize ultra-precision static pressure spindle Dynamic performance and other issues, to achieve the effect of accurate and reliable measurement results, simple and easy method, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

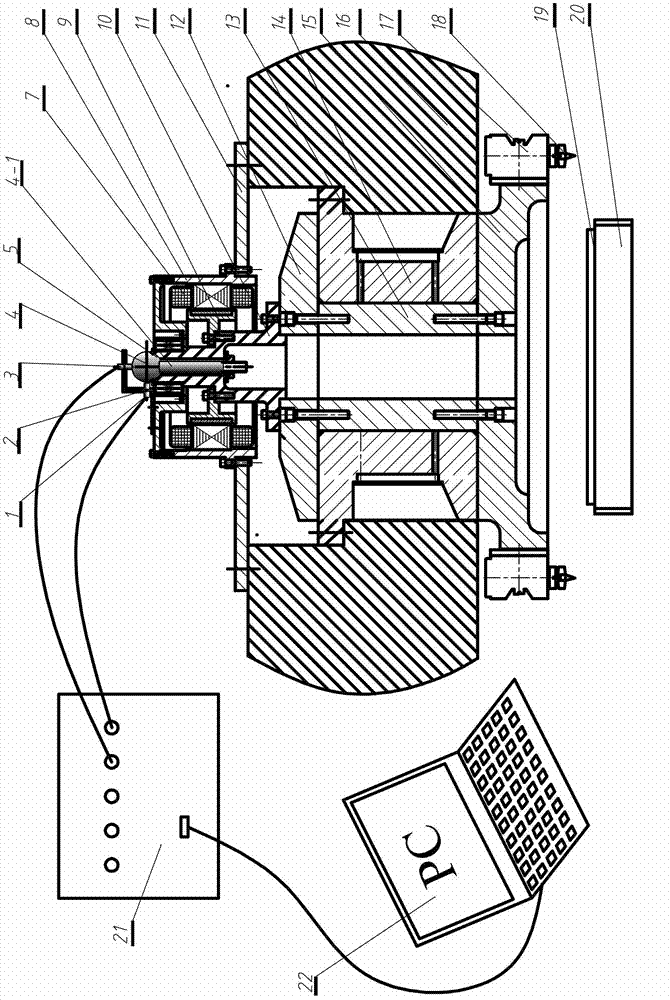

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the online testing method described in this embodiment is based on including vertical ultra-precision direct drive hydrostatic spindle system, measurement system and computer data acquisition and processing system 22 to realize;

[0011] Vertical ultra-precision direct-drive hydrostatic spindle system includes servo motor, ultra-precision direct-drive hydrostatic spindle or direct-drive ultra-precision hydrostatic spindle rotor (rotating part, namely rotor part), machine tool beam support plate (machine tool beam cover plate) 11, spindle bushing 14 (stator part), machine beam 16, micro-feed tool holder 17 and diamond cutter 18; the ultra-precision direct-drive hydrostatic spindle consists of input end components 10 coaxially arranged from top to bottom 1, the upper thrust plate 12, the shaft center 13, and the lower thrust plate 15 are fixedly connected; the servo motor includes a motor stator ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the specific implementation process of an ultra-precision static pressure spindle dynamic characteristic online detection method that eliminates the installation error of the measurement reference described in this embodiment is: Step 1, install the measurement reference: install the standard ball 4 on the static pressure In the tapered installation datum plane 5 processed at the rear end of the spindle system, the lower end of the detection rod 4-1 is fixed inside the input end component 10 (hollow spindle) of the direct-drive ultra-precision static pressure spindle through a nut; step 2, install High-precision displacement sensor: First, fix the high-precision displacement sensor bracket 2 on the casing of the motor stator, and then install two high-precision displacement sensors 1 and 3 through the mounting holes on the bracket 2, and install one of the high-precision displacement sensor ...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the standard ball of this embodiment is ground and polished, and the material is special stainless steel. After polishing, the PV value of the surface shape accuracy is better than λ / 20 (wherein λ=0.633 μm), and the surface roughness is better than 2nm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com