Synthesis method of diphenyl ketone hydrazone

A technology for the synthesis of benzophenone hydrazone, which is applied in the preparation of hydrazone, organic chemistry, etc., can solve the problems of unsafety, long reaction time, and low yield, and achieve the effects of increasing yield, process safety, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

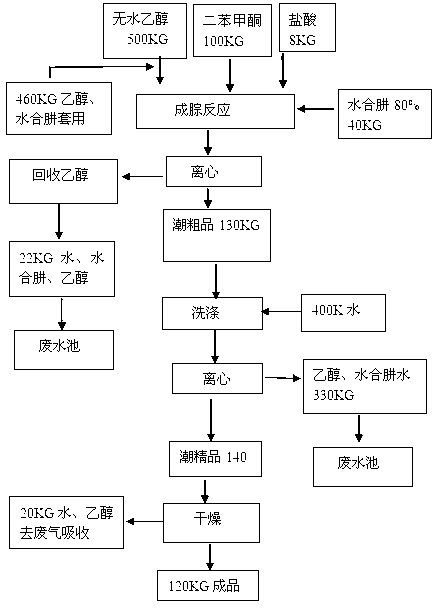

Method used

Image

Examples

Embodiment 1

[0019] After confirming that the equipment is all in good condition and that there is no foreign matter in the reactor, 500 kg of dehydrated alcohol is first vacuumed into the reactor, 100 kg of benzophenone is added, and then 40 kg of hydrazine hydrate and 8 kg of hydrochloric acid are drawn in.

[0020] After all the raw materials are put in, turn on the steam to raise the temperature. When the temperature of the material in the reactor reaches 95°C, start to bring water. The reaction solution was cooled to 10°C for crystallization, stirred for 1 hour, and then started to filter. During the filter, it was necessary to ensure that the filtrate was dried to ensure that there was no n-butanol dripping out of the outlet of the centrifuge. The filter time was 35 minutes.

[0021] After shaking, put the solid product into the reaction kettle, add 400 kg of pure water and about 400ml of glacial acetic acid for soaking, add the dried solid and stir for 2 hours, and start to filter af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com