Application method of cyclodextrin-aldehyde cross-linking agent

A technology of aldehyde crosslinking agent and application method, which is applied in the field of cyclodextrin and collagen crosslinking agent, can solve the problems of not being able to obviously improve the shortcomings of collagen materials, the color of collagen materials, and the potential for calcification, etc., and achieve improved thermal stability , Enhanced degradation resistance, good cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

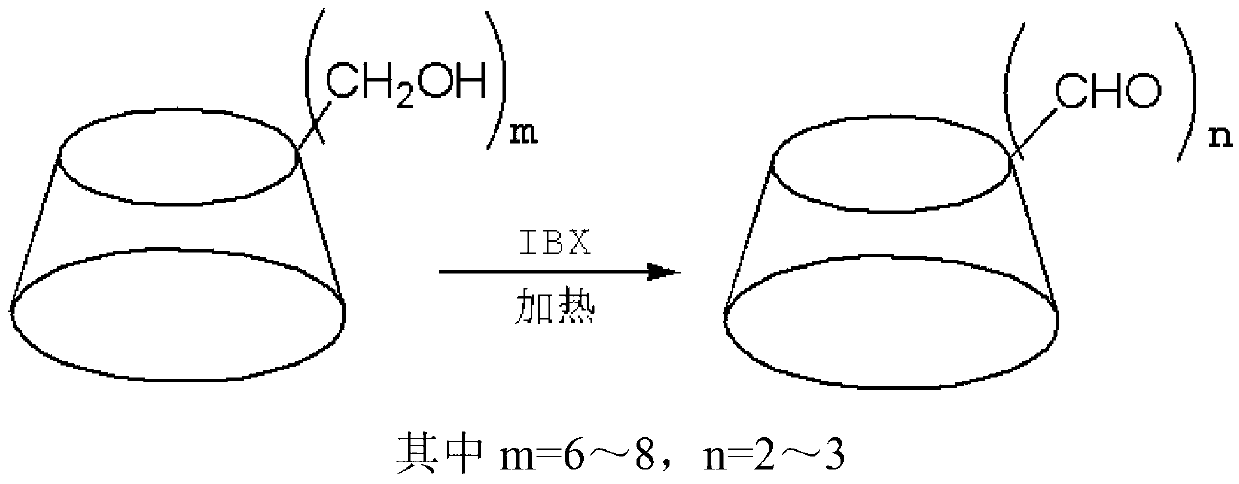

[0032] The synthetic method of cyclodextrin polyaldehyde crosslinking agent of the present invention comprises the steps:

[0033] (1) Add 0.5 mmol of purified cyclodextrin into 5-8 ml of dimethyl sulfoxide, and completely dissolve the cyclodextrin to obtain a mixture;

[0034] (2) Add 2.2 to 2.8 equivalents of 2-iodylbenzoic acid to the mixture obtained in step (1), and react for 30 to 48 hours at 25 to 30°C while keeping stirring, then filter the reaction solution and keep filtrate;

[0035] (3) Drop the filtrate obtained in step (2) into acetone, and filter to retain the precipitate;

[0036] (4) Vacuum-dry the precipitate obtained in step (3) at 30-40°C for 24 hours, and then dissolve it with deionized water;

[0037] (5) Filter the solution obtained in step (4), retain the filtrate, and freeze-dry the filtrate for 48 hours to obtain the cyclodextrin polyaldehyde crosslinking agent.

Embodiment 1

[0039] (1) Preparation of cyclodextrin polyaldehyde crosslinking agent:

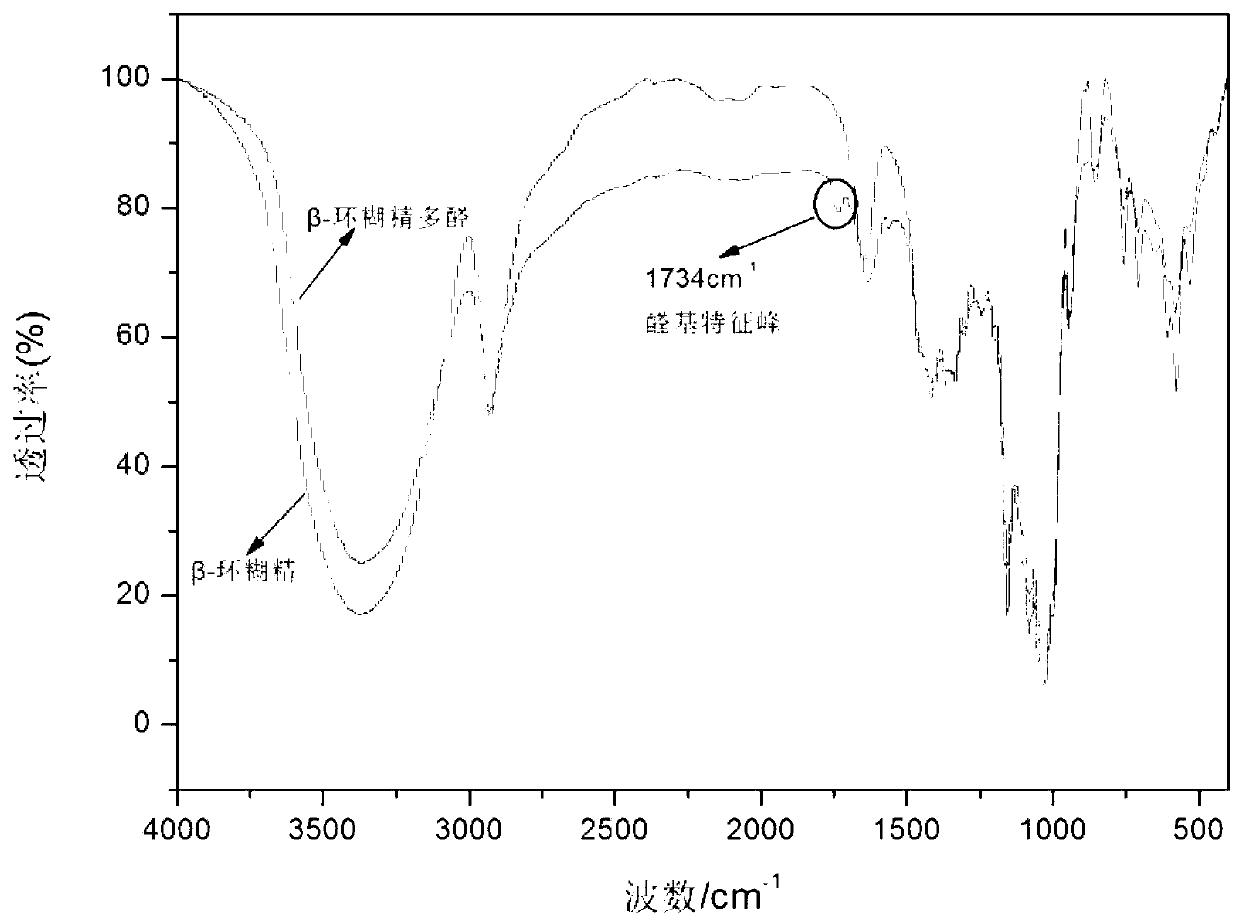

[0040] Weigh 0.5mmol of purified β-cyclodextrin in a 50ml flask, add 7ml of polar aprotic solvent dimethyl sulfoxide (DMSO) into the flask, magnetically stir the cyclodextrin until it is completely dissolved, then add 2.4 Equivalents of the mild oxidizing agent 2-iodobenzoic acid (IBX). Then react at 25°C for 48 hours under magnetic stirring, filter after the reaction, drop the filtrate into 150ml of acetone, filter the precipitated substance to obtain a precipitate, and dry the precipitate in a vacuum oven at 35°C for 24 hours , and finally the dried sample was dissolved with 50ml of deionized water, filtered to remove impurities, and the filtrate was freeze-dried to obtain a light yellow sample.

[0041] After testing, the yield of β-cyclodextrin polyaldehyde was 90%.

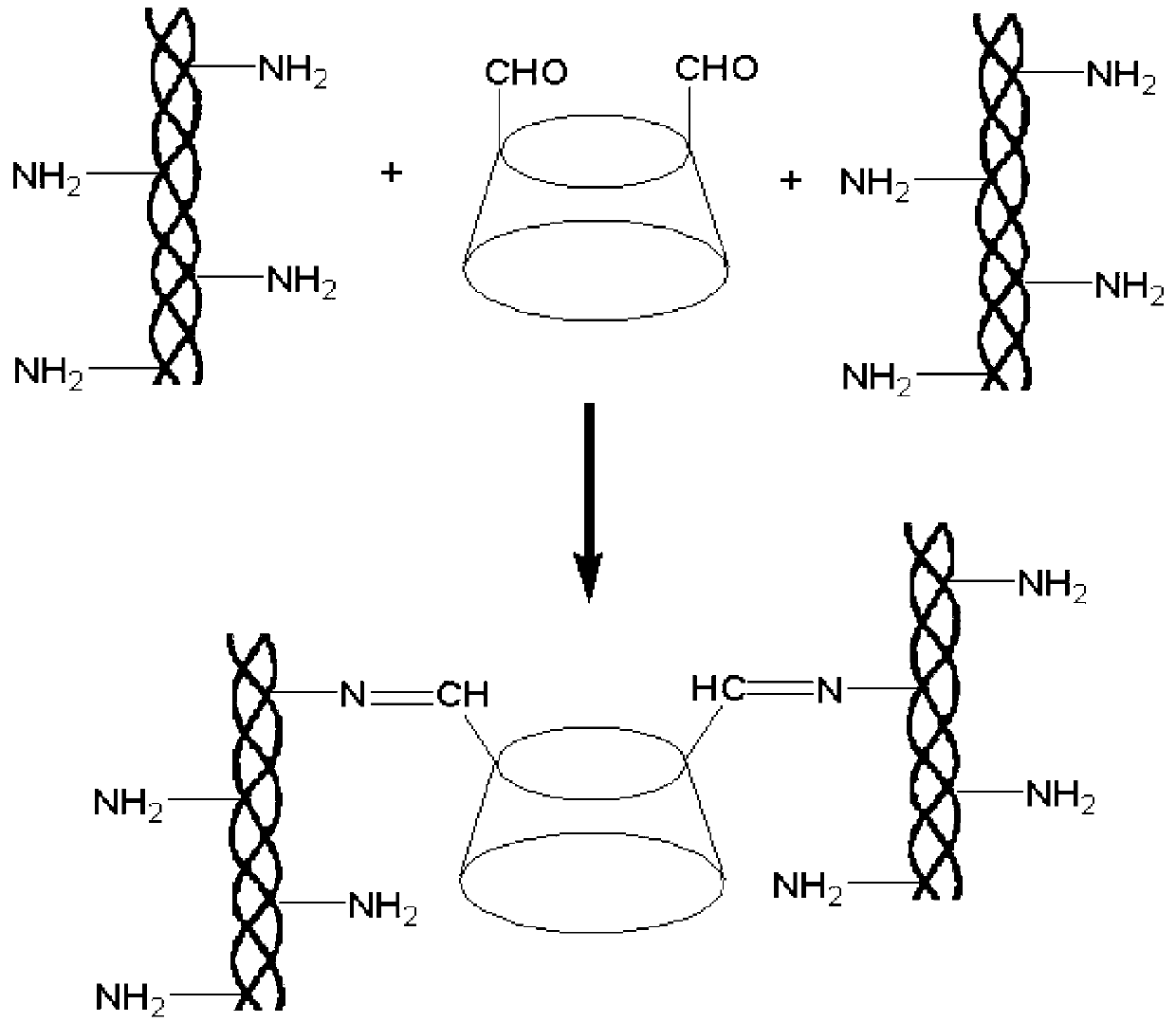

[0042] (2) Modified collagen:

[0043] The cyclodextrin polyaldehyde crosslinking agent prepared in step (1) was formulated into 5 ...

Embodiment 2

[0065] (1) Preparation of cyclodextrin polyaldehyde crosslinking agent:

[0066] Weigh 0.5mmol of purified γ-cyclodextrin in a 50ml flask, add 5ml of polar aprotic solvent dimethyl sulfoxide (DMSO) into the flask, magnetically stir the cyclodextrin until it is completely dissolved, then add 2.2 Equivalents of the mild oxidizing agent 2-iodobenzoic acid (IBX). Then react at 25°C for 30 hours under magnetic stirring, filter after the reaction, drop the filtrate into 150ml of acetone, filter the precipitated substance to obtain a precipitate, and dry the precipitate in a vacuum oven at 35°C for 24 hours , and finally the dried sample was dissolved with 50ml of deionized water, filtered to remove impurities, and the filtrate was freeze-dried to obtain the final sample.

[0067] After testing, the yield of cyclodextrin polyaldehyde was 87%.

[0068] (2) Modified collagen:

[0069] The cyclodextrin polyaldehyde crosslinking agent prepared in step (1) was formulated into 5 kinds o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat denaturation temperature | aaaaa | aaaaa |

| Heat denaturation temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com