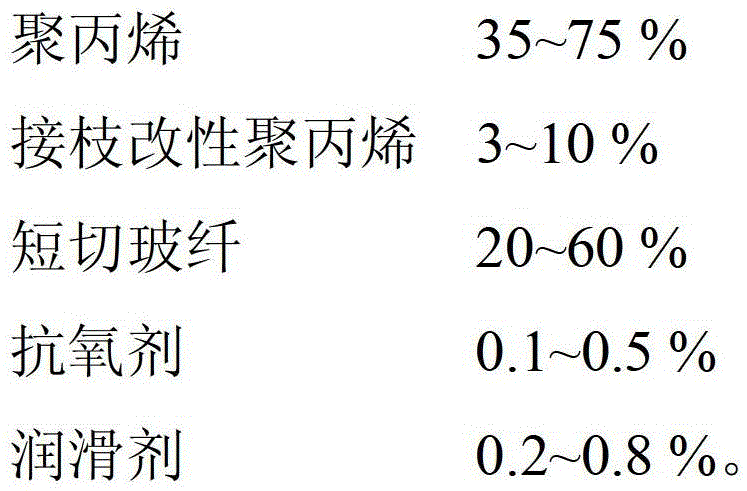

A kind of short glass fiber reinforced polypropylene composite material and its preparation method and application

A composite material, polypropylene technology, applied in the field of polypropylene modification, can solve problems such as performance degradation, glass fiber breakage and fracture, achieve high impact strength, reduce damage and damage, and retain long effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of short glass fiber reinforced polypropylene composite

[0039] Pre-mix other components other than chopped glass fiber, place the uniformly mixed material in the main feeding port of the twin-screw extruder, put the chopped glass fiber into the side feeding machine from the side feeding port, and melt and extrude. The pelletizing of the die surface under water was carried out to prepare the short glass fiber reinforced polypropylene composite material.

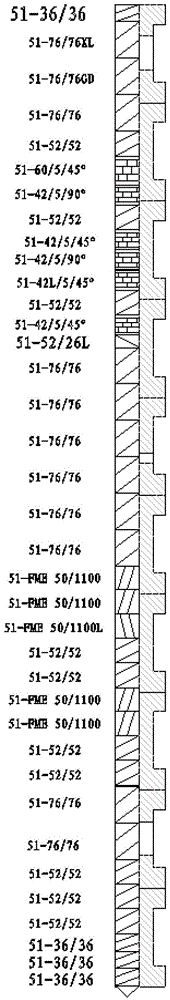

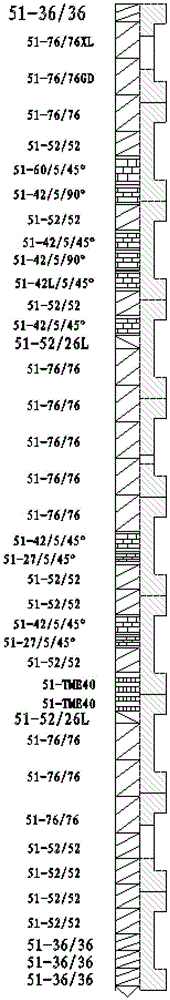

[0040] The side feeder has a length-to-diameter ratio of 8:1, a speed setting of 200rpm, and a heating function. The twin-screw extruder adopts a special screw element and screw combination, and the glass fiber dispersion area is a large-lead, non-meshing screw element. For specific parameters, see figure 1 (purchased from Sichuan Zhongzhuang Technology Co., Ltd.).

[0041] The melt extrusion process parameters are set as follows: the temperature of the first zone of the host machine is 140°C,...

Embodiment 2

[0043] Example 2: Preparation of short glass fiber reinforced polypropylene composite

[0044] Pre-mix other components other than chopped glass fiber, place the uniformly mixed material in the main feeding port of the twin-screw extruder, put the chopped glass fiber into the side feeding machine from the side feeding port, and melt and extrude. The pelletizing of the mold surface under water was carried out to prepare the short glass fiber reinforced polypropylene composite material.

[0045] The side feeder has a length-to-diameter ratio of 8:1, a speed setting of 200rpm, and a heating function. The twin-screw extruder adopts a special screw element and screw combination, and the glass fiber dispersion area is a large-lead, non-meshing screw element (purchased from Sichuan Zhongzhuang Technology Co., Ltd.).

[0046] The melt extrusion process parameters are set as follows: the temperature of the first zone of the main machine is 140°C, the temperature of the second zone is ...

Embodiment 3

[0048] Example 3: Preparation of short glass fiber reinforced polypropylene composite

[0049] Pre-mix other components other than chopped glass fiber, place the uniformly mixed material in the main feeding port of the twin-screw extruder, put the chopped glass fiber into the side feeding machine from the side feeding port, and melt and extrude. The pelletizing of the mold surface under water was carried out to prepare the short glass fiber reinforced polypropylene composite material.

[0050] The side feeder has a length-to-diameter ratio of 8:1, a speed setting of 200rpm, and a heating function. The twin-screw extruder adopts a special screw element and screw combination, and the glass fiber dispersion area is a large-lead, non-meshing screw element (purchased from Sichuan Zhongzhuang Technology Co., Ltd.).

[0051] The melt extrusion process parameters are set as follows: the temperature of the first zone of the main machine is 140°C, the temperature of the second zone is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com