Novel energy-saving emission-reduction sintering machine system and sintering method

A sintering machine system, energy-saving and emission-reduction technology, applied in the direction of furnace type, waste heat treatment, furnace, etc., can solve problems not related to energy-saving emission reduction and waste heat utilization, so as to save unit consumption, realize comprehensive utilization of resources, and reduce total emissions Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

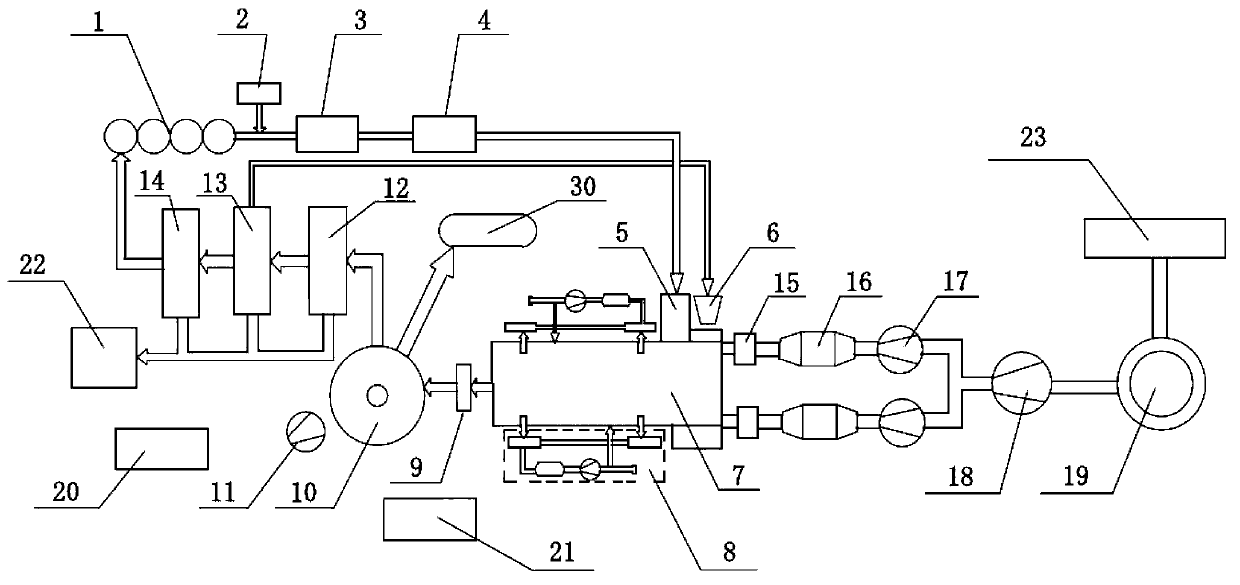

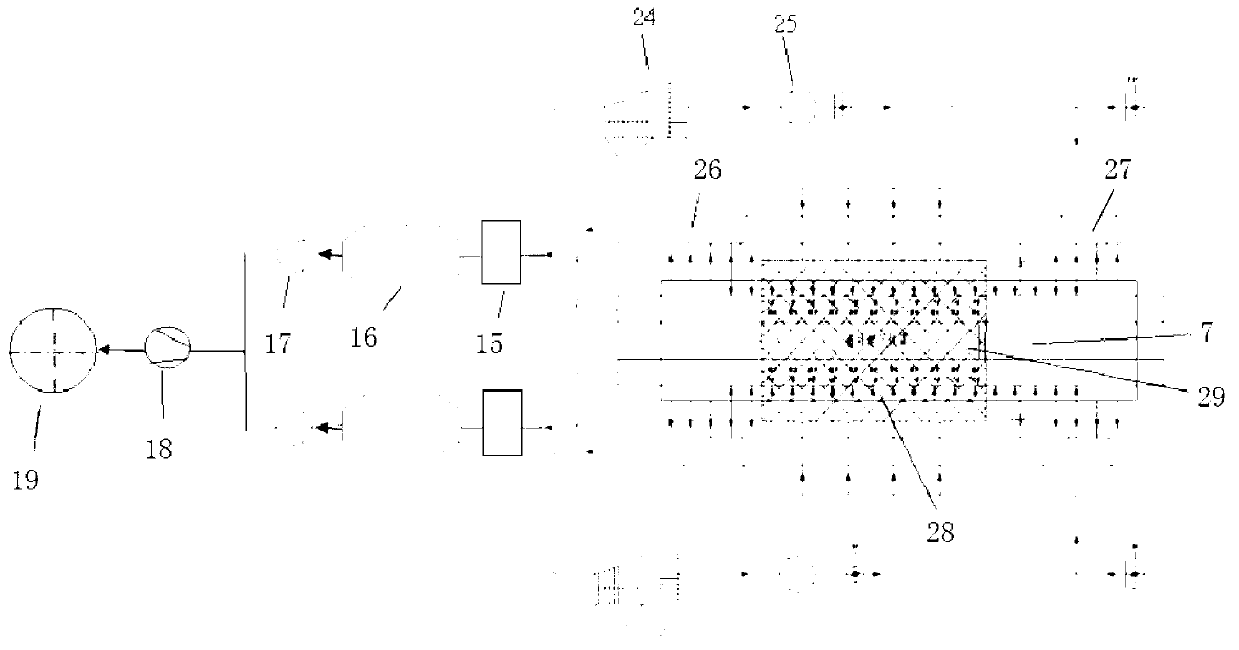

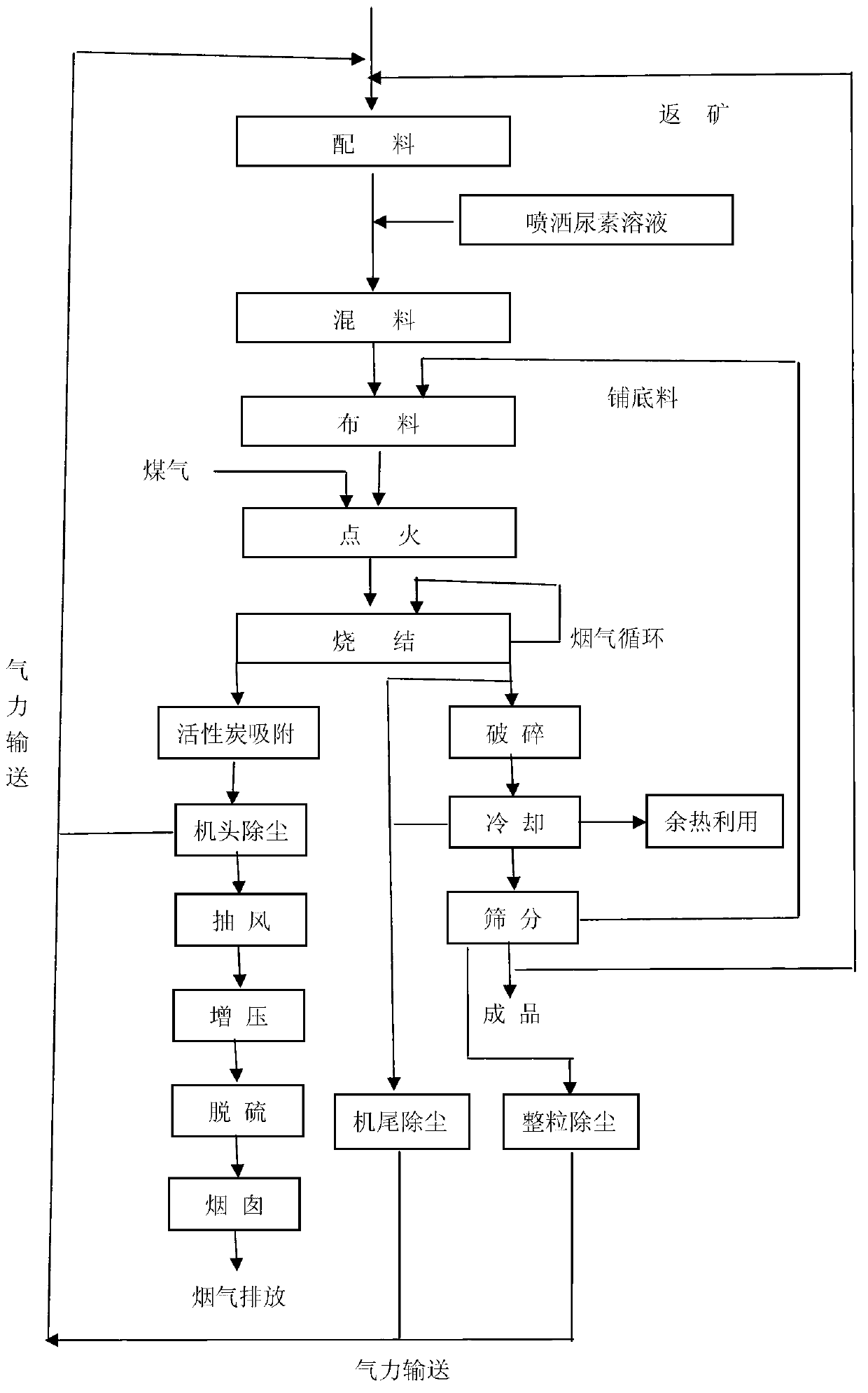

Embodiment 1

[0049] The production process of the sintering machine system includes: batching, mixing, distributing, sintering, cooling, whole particle screening, flue gas circulation, flue gas dust removal and desulfurization, sintering return ore, raw material ore, flux, solid fuel, iron-containing dust, etc. in batching Chamber 1 is automatically weighed, and then sent to primary mixing chamber 3 and secondary mixing chamber 4 through the feeding mechanism for mixing. The urea solution spraying device 2 installed between the batching chamber 1 and the primary mixing chamber 3 sprays the urea solution on the sintering raw material. After the sintering raw material is mixed twice, the mixture is sent to the mixture distributing device 5 by a belt conveyor. The distributing device 5 evenly arranges the mixture in the sintering chamber 7 . The sintering chamber 7 sinters the mixed material into a sintered cake. The flue gas produced by sintering in the sintering chamber 7 is adsorbed by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com