Optical gain performance test device of organic film

A test device and organic thin film technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of light intensity loss, unstable measurement of pump light source, error, etc., and achieve the effect of a reliable design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

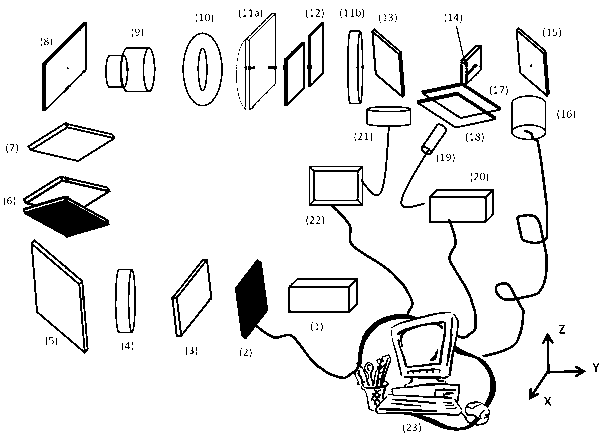

[0028] Measure the relationship between the ASE performance of the thin film material and the polarization direction of the pump light source with the optical path designed by the present invention: figure 1 Put the element into the light path, rotate the linear polarizer to the required direction, continuously reduce the full-wave attenuation plate, and make the pump light intensity from weak to strong, measure and record the sample spectrum as the incident light intensity changes, determine the ASE threshold, and then Put a half-wave plate into the optical path to change the polarization direction of the incident light by 90 o , keeping other components on the optical path unchanged, repeat the above measurement.

Embodiment 2

[0030] Measure the loss coefficient of thin film material with the optical path of the present invention design: press figure 1 Designing the optical path, this measurement does not require a linear polarizer and a half-wave plate, so these two components can be moved out of the optical path. Under a specific incident light intensity, the adjustable slit width is fixed, the position of the spectrometer probe is fixed, the sample is adjusted so that one edge of the rectangular spot is just at the edge of the sample, the ASE signal intensity and spectrum of the sample are recorded, and then the sample is moved to make the edge of the rectangular spot Move into the sample, such as 0.1mm, record the ASE signal intensity and spectrum of the sample again, continue to move the edge of the rectangular spot to the sample for the same distance, that is, 0.1mm, record the ASE signal intensity and spectrum of the sample, and repeat the measurement to obtain a set of The relationship curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com