Flue gas denitrification monitoring system and method

A monitoring system and flue gas technology, applied in the field of flue gas denitrification monitoring system, can solve the problems of high water content, high dust, large detection error, etc., and achieve the effects of low cost, improved service life, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

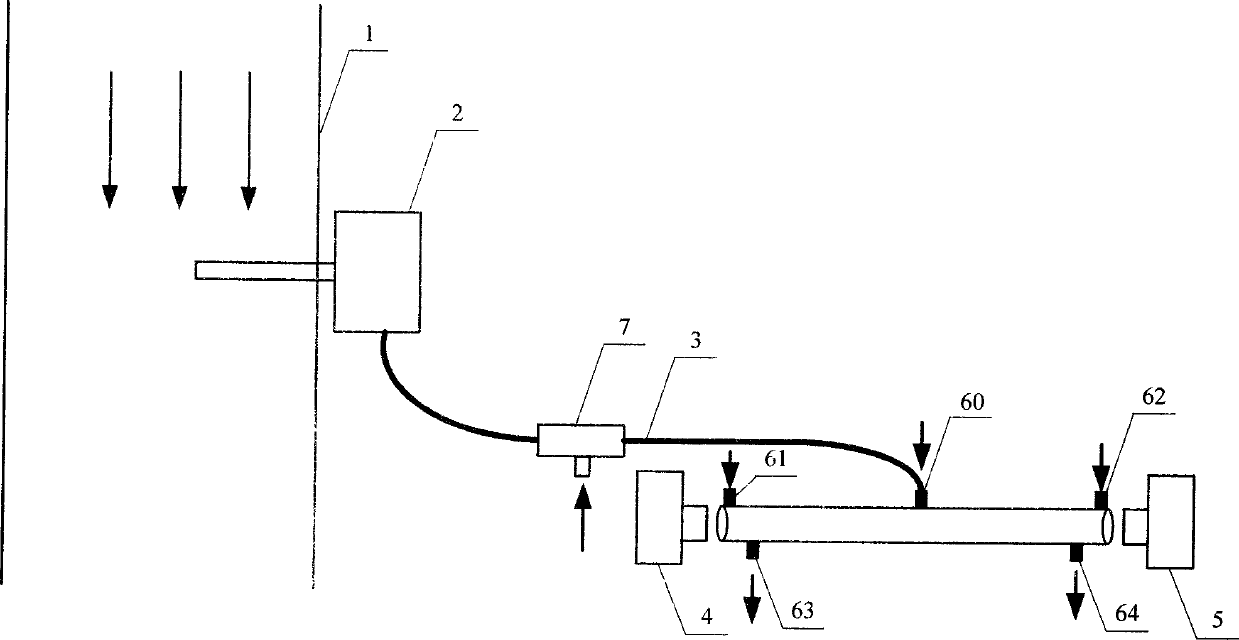

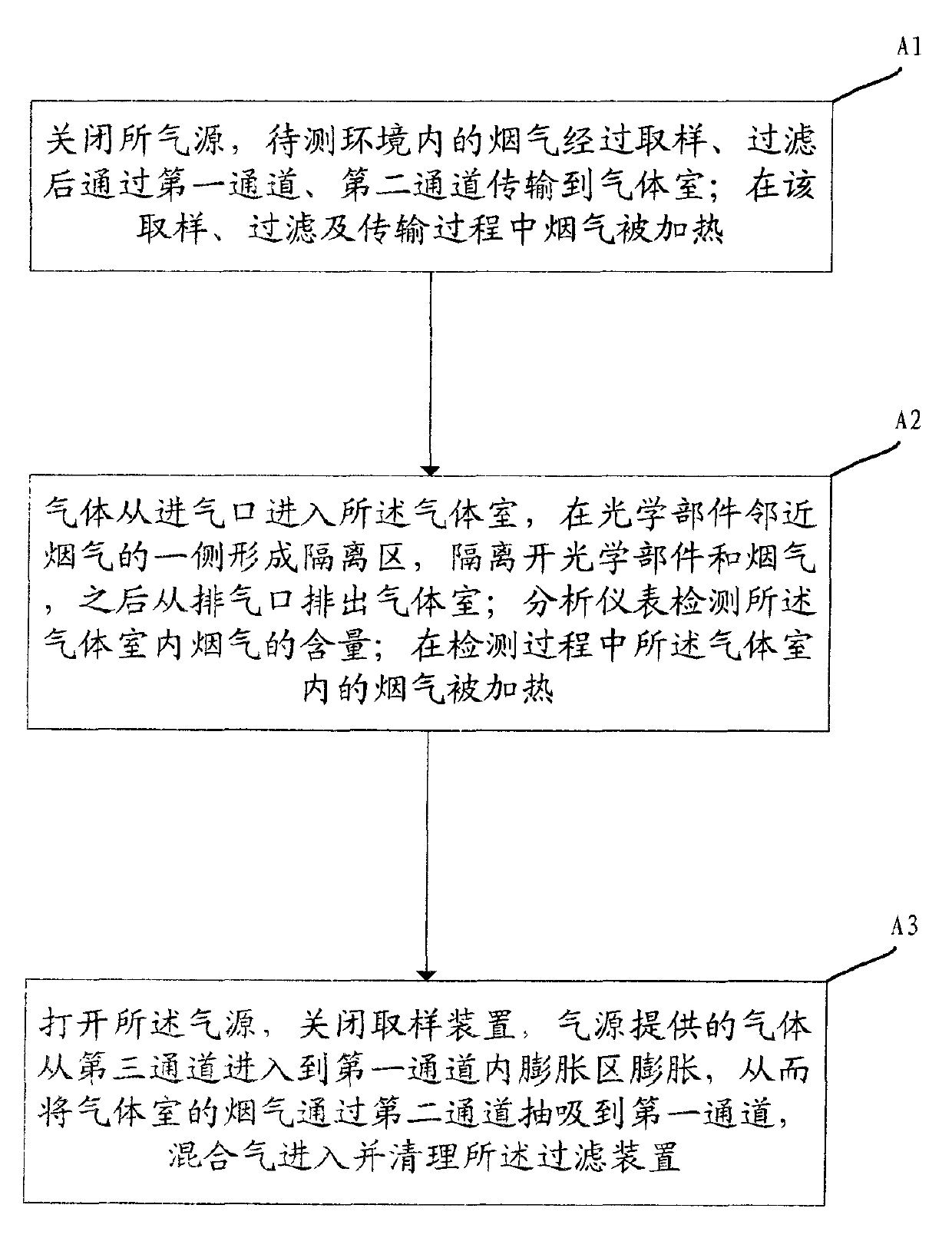

[0038] figure 1 Schematically provides a simplified structural diagram of the flue gas denitrification monitoring system of the embodiment of the present invention, as figure 1 As shown, the flue gas denitrification monitoring system includes:

[0039] The sampling device, the filtering device 2, the gas chamber and the analysis instrument are all prior art in this field, and will not be repeated here. The sampling device is installed on the flue 1.

[0040] A heating device, the heating device is used to heat the filter device, the gas chamber, and the pipeline connecting the filter device and the gas chamber; preferably, the temperature of the flue gas in the filter device 2, the pipeline 3 and the gas chamber exceeds 200°C by heating.

[0041] Isolation device, the isolation device is used to provide gas, the gas enters the gas chamber from the air inlet 61, forms an isolation area on the side of the optical component adjacent to the smoke, isolates the optical component ...

Embodiment 2

[0058] An application example of the flue gas denitrification monitoring system and method according to Embodiment 1 of the present invention in the monitoring of escaped ammonia.

[0059] In the flue gas denitrification monitoring system of this application example, the filter device adopts a ceramic filter with a filtration accuracy of 20 μm; an electric heating block is installed in the box of the filter device, an electric heating cable is installed on the pipeline, and the gas chamber is made of stainless steel. Cartridge, mounted in a box with an electric heating block. The two ends of the gas chamber are respectively provided with optical windows and reflectors, and the air inlets for the isolation gas are arranged on the gas chamber on the side of the optical windows and reflectors adjacent to the flue gas. The gas chamber between the gas ports (such as the middle of the gas chamber on the same side as the air inlet) is provided with a smoke inlet, and the two exhaust ...

Embodiment 3

[0065] An application example of the flue gas denitrification monitoring system and method according to Embodiment 1 of the present invention in the monitoring of escaped ammonia.

[0066] In the flue gas denitrification monitoring system of this application example, the filter device adopts a silk filter with a filtration accuracy of 8μn; an electric heating block is installed in the filter device, an electric heating cable is installed on the pipeline, and a cylinder made of stainless steel is used in the gas chamber. Installed in a box with electric heating block. The two ends of the gas chamber are respectively provided with a first optical window and a second optical window, and the gas chamber on the side of the first optical window and the second optical window adjacent to the flue gas is provided for the passage of isolation gas. The gas inlet is set on the gas chamber between the two gas inlets (such as in the middle of the gas chamber on the same side as the gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com