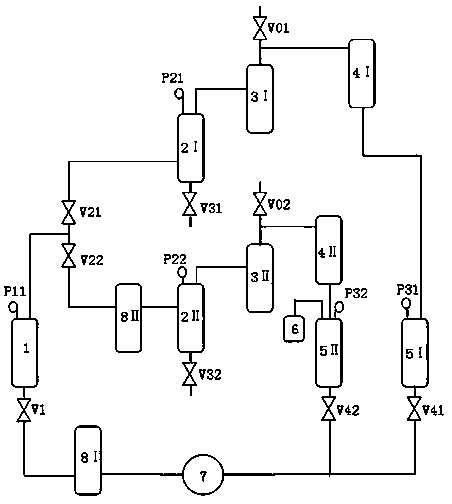

Multifunctional continuous phase transition extraction device

An extraction device and multi-functional technology, which is applied in the new device field of multi-functional continuous phase change extraction technology in extraction and separation, can solve the problems of equipment volume enlargement, limitation, low extraction temperature and pressure, etc., and achieves high efficiency and full function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Camellia oil fruit (crushed to 20 mesh, dried to make the moisture ≤ 5%) weighed 7KG, put it directly into the extraction tank 1, pressurized by the high-pressure pump 7 to make n-butane pass through the heat exchanger 8I, and enter Extraction in the extraction tank 1, the extraction temperature is 45°C, and the extraction pressure is 0.5MPa; the solvent passing through the extraction tank 1 enters the analysis tank 2I with oil, and is analyzed in the analysis tank 2I, the temperature of the analysis tank 2I is 55 °C, and the pressure 0.25MPa; the whole extraction time is 50min, and 1.94KG product is obtained in the first bottom valve V31 of the analysis tank 2I, and the extraction rate is verified to be 99.3%.

[0031] (2) After the oil is extracted, switch to the passage extraction tank 1, heat exchanger 8II, second pressure control valve V22, second analysis tank 2II, second purification column 3II, second condenser 4II, and second solvent tank 5II , the second v...

Embodiment 2

[0033] (1) Weigh 10KG of castor beans, press hydraulic pressure first, squeeze out 3KG of oil, then crush the meal to 20 mesh, dry to make the moisture ≤ 5%, put it directly into the extraction tank 1, and pressurize it by the high-pressure pump 7 Make n-butane pass through the first heat exchanger 8I, and then enter the extraction tank 1 for extraction, the extraction temperature is 80°C, and the extraction pressure is 1.0MPa; the solvent passing through the extraction tank 1 enters the first analysis tank 2I with oil , analyzed in the first analysis tank 2I, the analysis temperature is 60°C, the pressure is 0.3MPa, the whole extraction time is 150min, and 1.97KG product is obtained in the first bottom valve V31 of the first analysis tank 2I, and the verified extraction rate is 98.5 %.

[0034] (2) After the oil is extracted, switch to the passage extraction tank 1, the second heat exchanger 8II, the second pressure control valve V22, the second desorption tank 2II, the secon...

Embodiment 3

[0036] (1) Weigh 7KG of soybeans fermented with soy sauce (crushed to 40 mesh, dried to make the moisture ≤ 10%), put them directly into the extraction tank 1, pressurize the high-pressure pump 7 to make the propane pass through the heat exchanger 8I, and enter Extract in the extraction tank 1, the extraction temperature is 45°C, and the extraction pressure is 1.2MPa; the solvent passing through the extraction tank 1 enters the first analysis tank 2I with oil, and is analyzed in the first analysis tank 2I, and the analysis temperature is 60 ℃, the pressure is 0.35MPa, the whole extraction time is 65min, and 2.02KG product is obtained in the first bottom valve V31 of the first desorption tank 2I, and the extraction rate is verified to be 99%.

[0037] (2) After the oil is extracted, switch to the passage extraction tank 1, the second heat exchanger 8II, the second pressure control valve V22, the second desorption tank 2II, the second purification column 3II, the second condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com