Nitrogen fertilizer high-molecular composite synergist, and preparation method thereof

A compound synergistic and compounding method technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of high cost, complicated preparation process, and inability of enhancers to improve soil nutrient environment, etc., so as to improve utilization efficiency and improve soil aggregates. Structure, effect on stimulating root development of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Field application test of macromolecule compound nitrogen fertilizer synergist

[0019] The purpose of the experiment: to compare the effects of nitrogen fertilizer synergists on crop yield, nitrogen fertilizer use efficiency and water use efficiency in the field production of semi-arid areas, combined with the actual corn production.

[0020] General situation of the test site: The polymer compound nitrogen fertilizer synergist developed by the present invention was used to carry out field tests at the China University of Mining and Technology (Beijing) and the Shenmu Erosion and Environment Test Station of the Institute of Soil and Water Conservation of the Chinese Academy of Sciences. The station is located in the Liudaogou River Basin 14km west of Shenmu County, Shaanxi Province, next to the Great Wall in the north, and in the transition zone between the Loess Plateau and the Mu Us Desert. The regional climate belongs to the semi-arid grassland monsoon...

example 2

[0025] Example 2: Leaching and pot experiment of polymer compound nitrogen fertilizer synergist

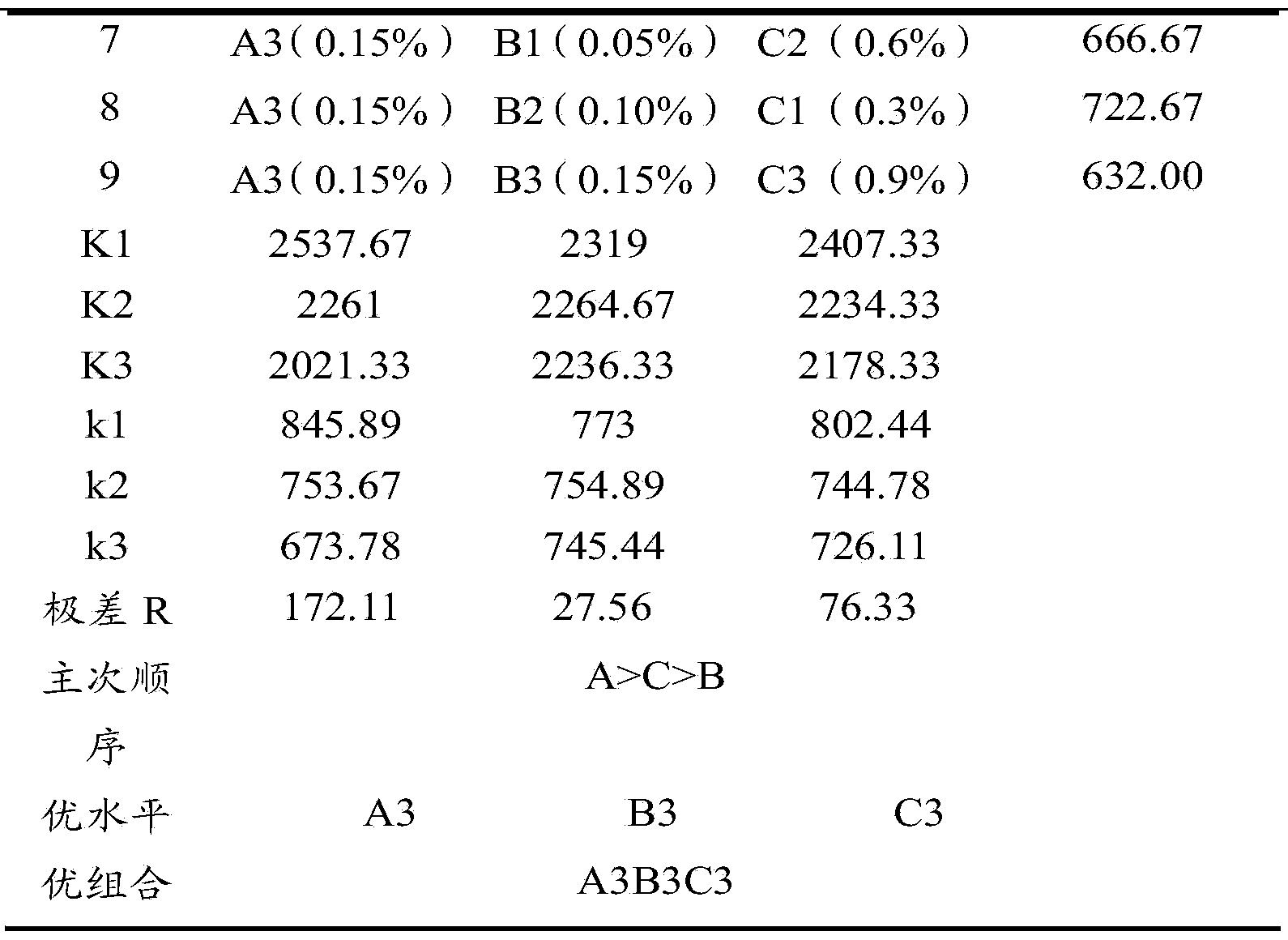

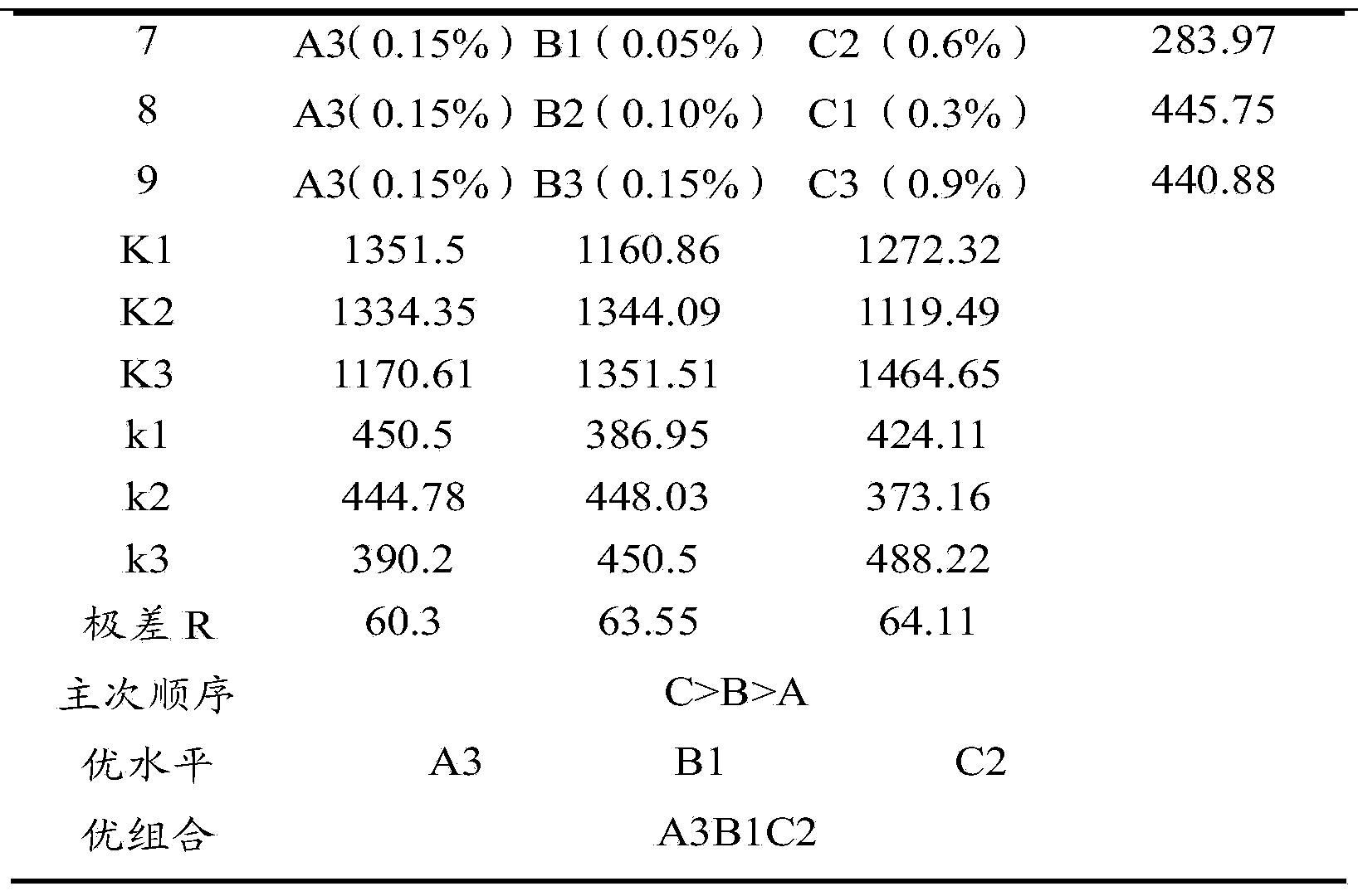

[0026] The purpose of the experiment: to simulate the leaching of nitrogen fertilizer and water in the farmland soil after applying the nitrogen fertilizer polymer compound synergist, as well as the effect on crop growth, to select and determine the optimal combination of components of the nitrogen fertilizer polymer compound synergist.

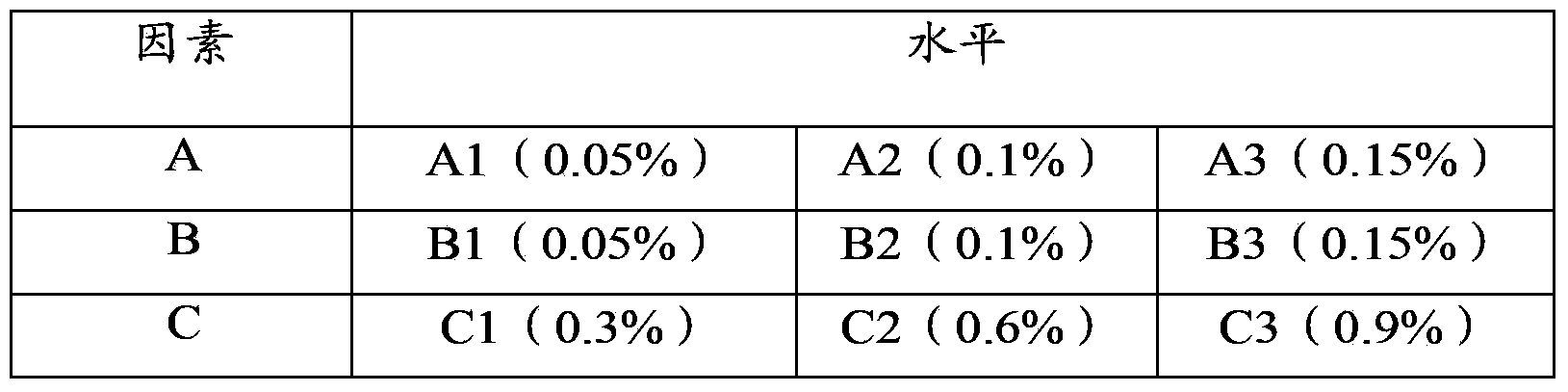

[0027] Experimental method and treatment: The experiment is divided into soil column leaching experiment and potted crop planting experiment method; the experimental design adopts the orthogonal experiment method of three factors and three levels. The soil for both experiments was light loam from Daxing, Beijing, with a bulk density of 1.39g / cm3 and a field water holding capacity of 19.3%. The soil composition was: clay 14.25%, silt 56.26%, sand 29.49%, and soil pH 7. 22. The electrical conductivity is 0.17ms / cm, and the organic matter content is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com