TiO2 slurry used in large-area dye-sensitized solar cell preparation by screen printing technology and method for preparing the TiO2 slurry

A solar cell, dye sensitization technology, applied in the field of TiO2 slurry and its preparation, can solve problems such as cracking and peeling, achieve the effect of improving photoelectric transmission efficiency, increasing light capture ability, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

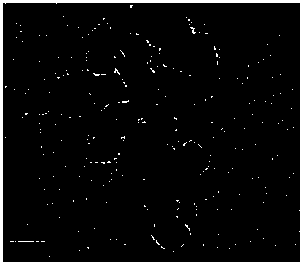

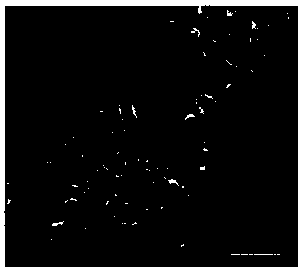

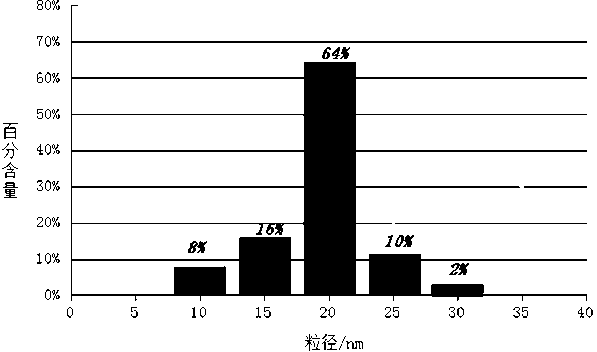

[0030] Preparation of TiO with a particle size of 20nm 2 :

[0031] (1) Weigh 29g of titanium tetraisopropoxide, 6g of glacial acetic acid, add glacial acetic acid dropwise in titanium tetraisopropoxide, stir for 10 ~ After 15 minutes, add the solution dropwise to 143g of deionized water within 3-5 minutes to produce a white flocculent precipitate, and stir vigorously for 1 hour;

[0032] Add 2.6ml of concentrated nitric acid (commercially available 65wt%, 1.4g / ml) dropwise to the above-mentioned flocculent solution, and preheat the solution: within 40min from room temperature to 80°C, and keep it warm for 50min to obtain a transparent Light blue colloidal solution, cooled to room temperature;

[0033] Dilute the above colloidal solution to 185mL with deionized water, pour it into a 250ml autoclave, and react under high pressure at 240°C for 12h;

[0034] After the reaction, add 1.2ml of concentrated nitric acid dropwise to the reaction solution, ultrasonically disperse, ce...

Embodiment 2

[0041] Preparation of TiO with a particle size of 20nm 2 :

[0042] (1) Weigh 36.6g of titanium tetraisopropoxide, 7.7g of glacial acetic acid, add glacial acetic acid dropwise in titanium tetraisopropoxide, stir for 10 ~ After 15 minutes, add the solution dropwise to 181g of deionized water within 3-5 minutes to produce a white flocculent precipitate, and stir vigorously for 1 hour;

[0043]Add 3.5ml of concentrated nitric acid (commercially available 65wt%, 1.4g / ml) dropwise to the above-mentioned flocculent solution, and preheat the solution: within 45min from room temperature to 80°C, and keep it warm for 50min to obtain a transparent Light blue colloidal solution, cooled to room temperature;

[0044] Dilute the above colloidal solution to 239mL with deionized water, pour it into a 300ml autoclave, and react under high pressure at 230°C for 12h;

[0045] After the reaction, add 1.52ml of concentrated nitric acid dropwise to the reaction solution, ultrasonically disperse...

Embodiment 3

[0052] Preparation of TiO with a particle size of 20nm 2 :

[0053] (1) Weigh 50g of titanium tetraisopropoxide, 10.24g of glacial acetic acid, add glacial acetic acid dropwise in titanium tetraisopropoxide, stir for 10 ~ After 15 minutes, add the solution dropwise to 247.4g of deionized water within 3-5 minutes to produce a white flocculent precipitate, and stir vigorously for 1 hour;

[0054] Add 4.75ml of concentrated nitric acid (commercially available 65wt%, 1.4g / ml) dropwise to the above-mentioned flocculent solution, and preheat the solution: within 50min from room temperature to 80°C, and keep it warm for 50min to obtain a transparent Light blue colloidal solution, cooled to room temperature;

[0055] Dilute the above colloidal solution to 320mL with deionized water, pour it into a 500ml autoclave, and react under high pressure at 240°C for 12h;

[0056] After the reaction, add 1.2ml of nitric acid dropwise to the reaction solution, ultrasonically disperse, centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com