Multi-ceramic layer patterned structural substrates for optical and electronic devices

A technology for electronic devices and ceramic layers, applied in the field of electronics, can solve problems such as electrical conduction short-circuit and difficult heat transfer, achieve good electrical isolation and thermal isolation, solve heat dissipation problems, and high withstand voltage breakdown performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

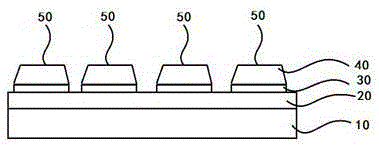

[0022] as attached figure 1 As shown, the multi-ceramic layer patterned structural substrate for optical and electronic devices described in this embodiment includes an aluminum or aluminum alloy substrate 10, and a SiC pressure-resistant ceramic layer 20 and AlN are sequentially formed on the metal substrate. High thermal conductivity ceramic layer 40; there is an aluminum transition layer 30 between the SiC pressure-resistant ceramic layer 20 and the AlN high thermal conductivity ceramic layer 40, and the AlN high thermal conductivity ceramic layer 40 and the aluminum transition layer 30 are selectively selected by a mask Etching forms a plurality of isolation pedestals 50; and forming a metal circuit layer (not shown in the figure) on the uppermost layer of the multi-ceramic layer of the isolation pedestals. The SiC pressure-resistant ceramic layer is prepared by an arc ion plating deposition method, and the thickness is 200um. Wherein, the step of the aluminum transition ...

Embodiment 2

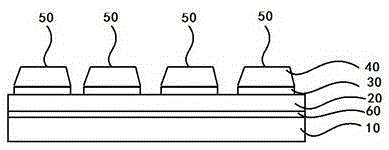

[0024] as attached figure 2 As shown, the multi-ceramic layer patterned structural substrate for optical and electronic devices described in this embodiment includes an aluminum or aluminum alloy substrate 10, and a SiC pressure-resistant ceramic layer 20 and AlN are sequentially formed on the metal substrate. High thermal conductivity ceramic layer 40; there is an aluminum transition layer 30 between the SiC pressure-resistant ceramic layer 20 and the AlN high thermal conductivity ceramic layer 40, and an active braze is arranged between the aluminum alloy substrate 10 and the SiC pressure-resistant ceramic layer 20 Welding layer 60; and selectively etch the AlN high thermal conductivity ceramic layer 40 and the aluminum transition layer 30 through a mask to form a plurality of isolation bases 50; and form on the uppermost layer of the multi-ceramic layer of the isolation base metal circuit layer (not shown in the figure). The SiC pressure-resistant ceramic layer is prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com