A parallel sub-module for flexible direct current transmission

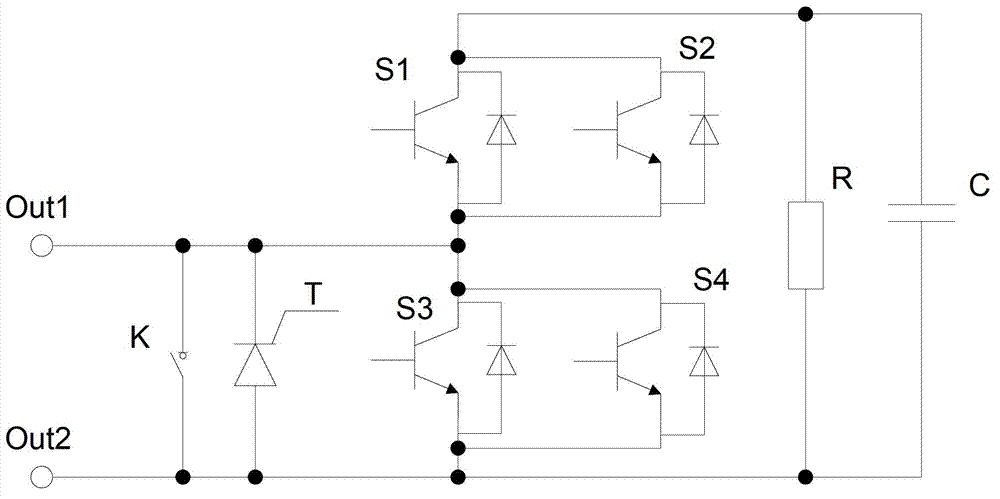

A flexible DC power transmission and sub-module technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of inconvenient maintenance of the system, scattered sub-module structure layout, etc., to achieve easy installation and component replacement, easy quality control, pressure uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

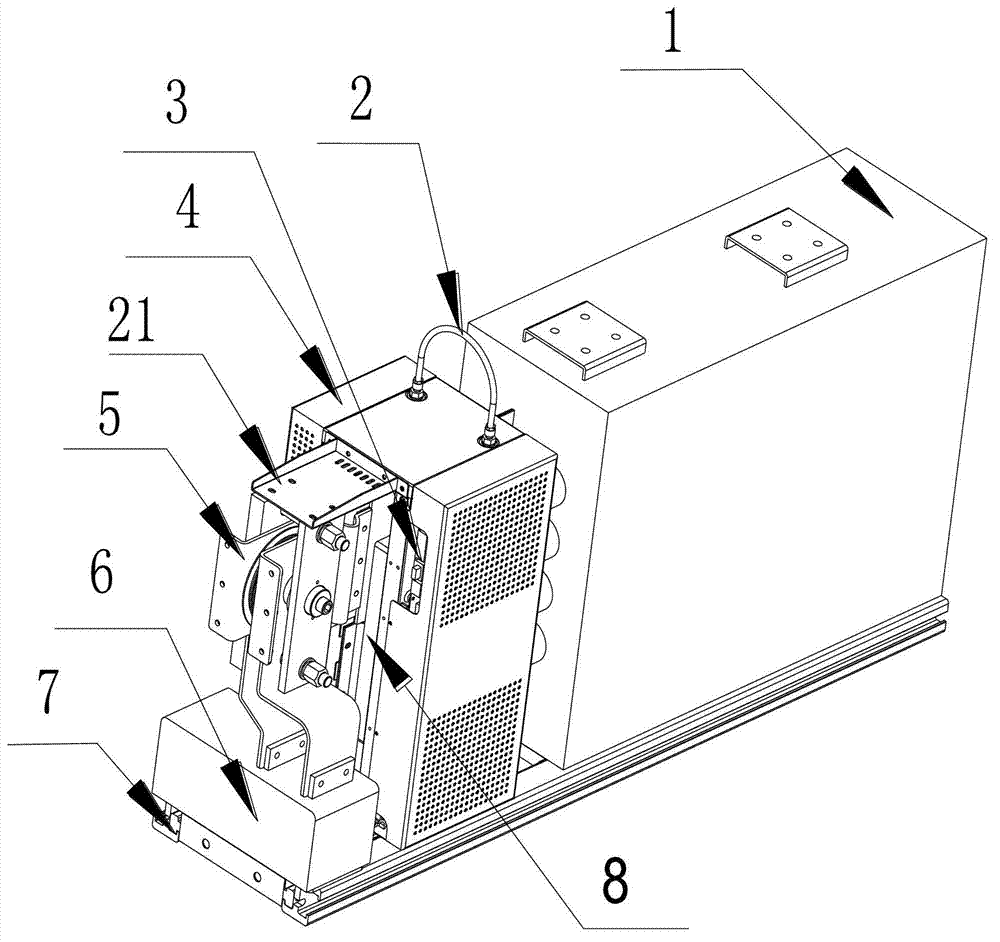

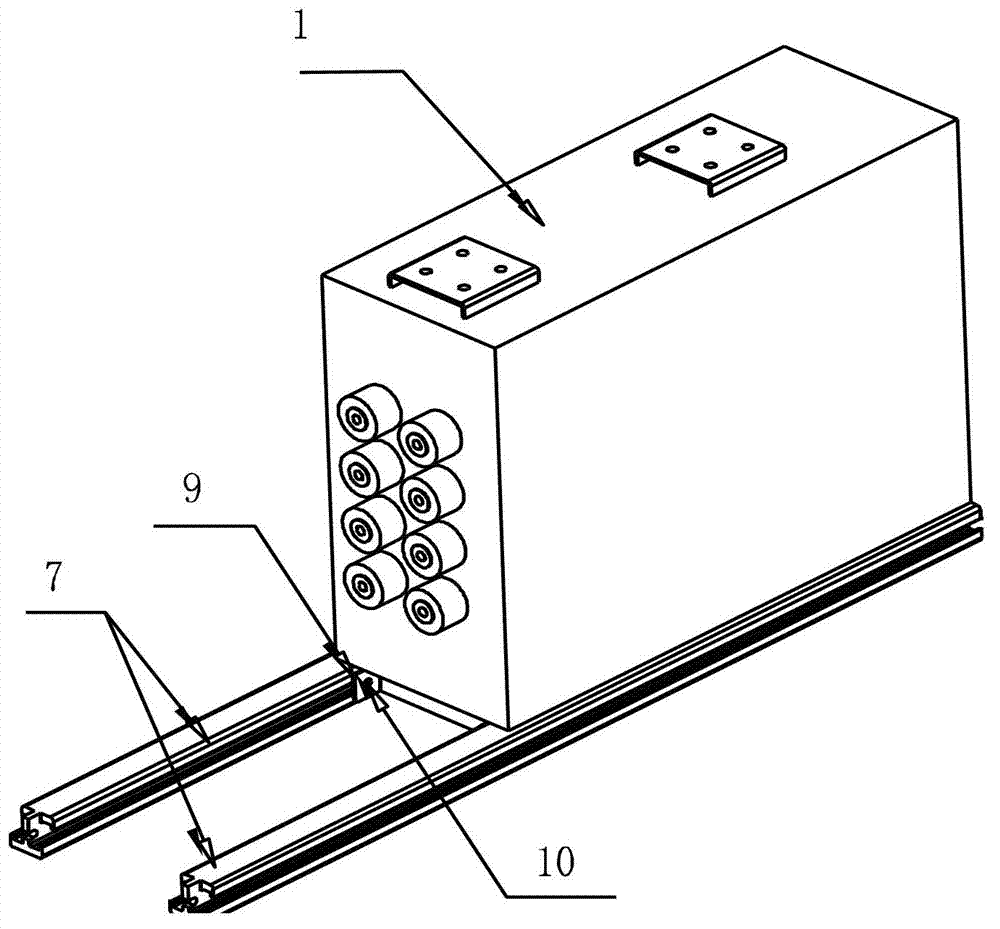

[0032] Such as figure 2 Shown is the overall structural diagram of the flexible direct current transmission sub-module of the present invention. It can be seen from the figure that the sub-module includes a capacitor 1, two IGBT power units and two main busbars; each IGBT power unit includes a radiator 17, a parallel More than two IGBT modules 8 and their control loops 3, the radiator is a plate radiator, the IGBT modules 8 on each power unit are installed side by side on a panel of the corresponding panel radiator 17, and the control loop is correspondingly installed on the panel On the other board of the radiator, each IGBT power unit also includes a composite busbar 18, the composite busbar is connected to the surface of the corresponding IGBT module away from the plate radiator, and the composite busbar is provided with a The outlet end of the corresponding connection of the busbar, the capacitor connection end for connecting to the capacitor, and the connecting terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com