Preparation method of filter core capable of fast and efficiently adsorbing caesium

An adsorption filter element, high-efficiency technology, applied in the field of adsorption materials for radioactive substances, can solve the problems of low efficiency and slow material speed, and achieve the effect of stable adsorption performance and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

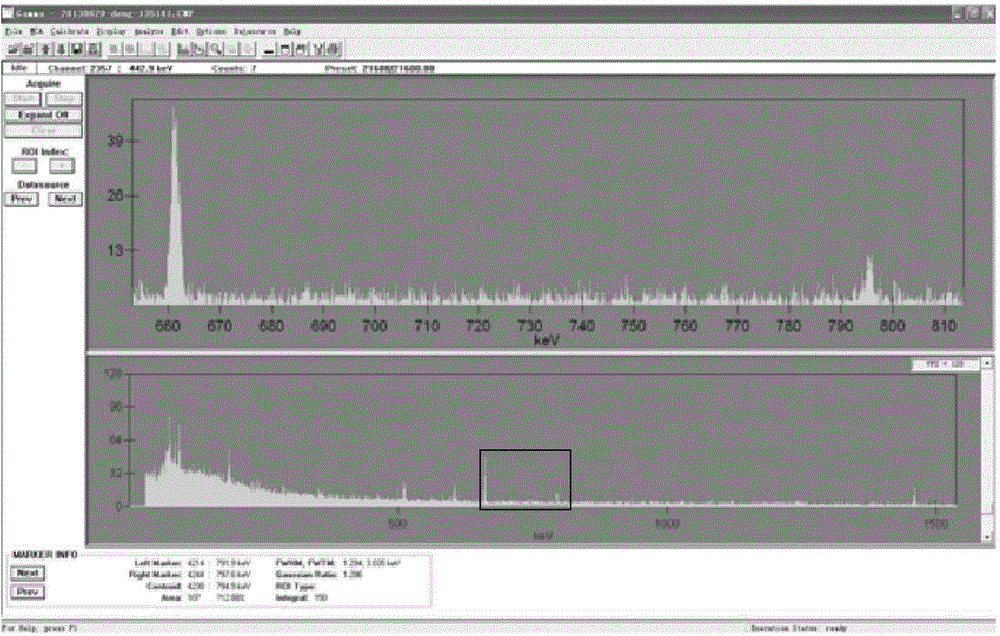

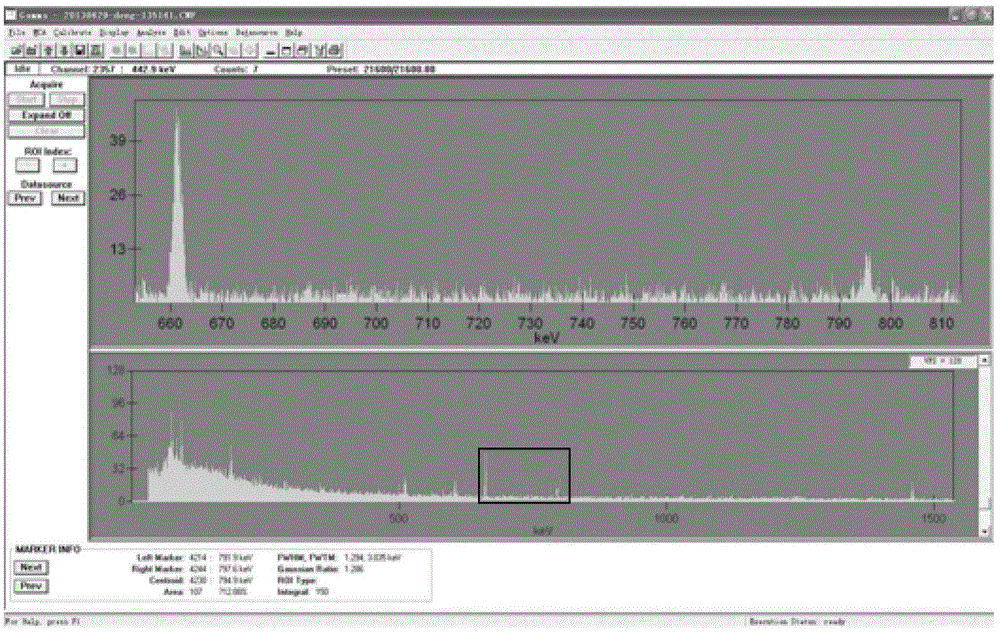

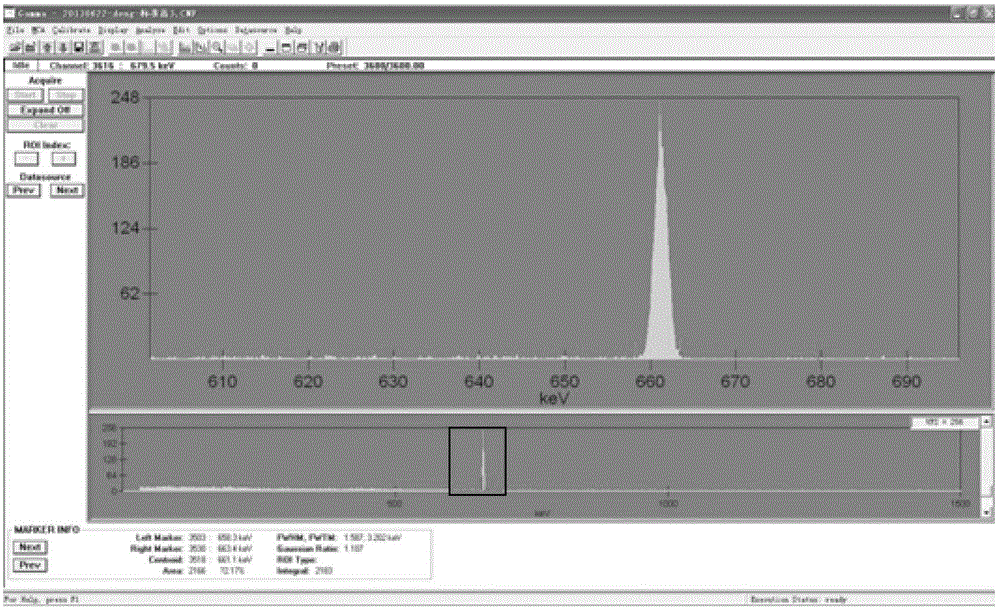

Image

Examples

Embodiment 1

[0037] The preparation method of the fast and highly efficient filter element for absorbing cesium, the specific preparation method is as follows:

[0038] 1) Modification of substrate material:

[0039] Add 1% by weight of methyl methacrylate and 1% of AMP (Ammonium Phosphomolybdate Trihydrate, ammonium phosphomolybdate) to the substrate material PP (polypropylene resin), heat to 160 ° C, stir and mix, so that PP is combined with AMP.

[0040] 2) Meltblown filter element:

[0041] The material prepared in step 1) is spun through 5 μm micropores, and the spun filaments are wound on the rotating cylindrical skeleton material to form an adsorption filter element with a thickness of 5 mm. The skeleton material is a hollow polypropylene melt-blown tube , the nominal particle size is 5μm.

[0042] 3) Coating of the filter element:

[0043] AMP is evenly coated on the outer surface of the adsorption filter element prepared in step 2), and the specific steps of coating are: disso...

Embodiment 2

[0047] The preparation method of the fast and highly efficient filter element for absorbing cesium, the specific preparation method is as follows:

[0048] 1) Modification of substrate material:

[0049] Add 3% styrene and 10% AMP to the substrate material PES (polyether sulfone resin, Poly ether sulfones), heat to 220 ° C, stir and mix, so that PES and AMP are combined;

[0050] 2) Meltblown filter element:

[0051] The material prepared in step 1) is spun through micropores of 5 μm, and the spun filaments are wound on a rotating cylindrical skeleton material to form an adsorption filter element with a thickness of 50 mm. The skeleton material is a hollow polypropylene melt Nozzle, the nominal particle size is 5μm.

[0052] 3) Coating of the filter element:

[0053] AMP is evenly coated on the surface of the adsorption filter element prepared in step 2), and the specific steps of coating are: dissolving AMP in ammonia water with a concentration of 0.5mol / L, wherein the mass ...

Embodiment 3

[0057] The preparation method of the fast and highly efficient filter element for absorbing cesium, the specific preparation method is as follows:

[0058] 1) Modification of substrate material:

[0059] Add 2% methyl methacrylate and 5% AMP to the substrate material: PP by weight, heat to 190°C, stir and mix well to combine PP and AMP;

[0060] 2) Meltblown filter element:

[0061] The material prepared in step 1) is spun through 5 μm micropores, and the spun filaments are wound on the rotating cylindrical skeleton material to form an adsorption filter element with a thickness of 30 mm. The skeleton material is a hollow polypropylene melt Nozzle, nominal particle size 5μm;

[0062] 3) Coating of the filter element:

[0063] On the surface of the adsorption filter element prepared in step 2), the specific steps of coating are: dissolving AMP in ammonia water with a concentration of 0.5mol / L, wherein the mass percentage concentration of AMP is 5%, and then , at 55°C, pH=3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com