Preparation method of narrow graphene nanoribbons

A nano-narrow band and graphene technology, applied in the direction of graphene, nano-carbon, carbon nanotubes, etc., can solve the problems of difficulty in controlling the size of graphene strips, difficulty in patterned arrangement of catalyst particles, difficulty in controlling size and shape, etc. Achieve the effect of easy size, simple preparation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

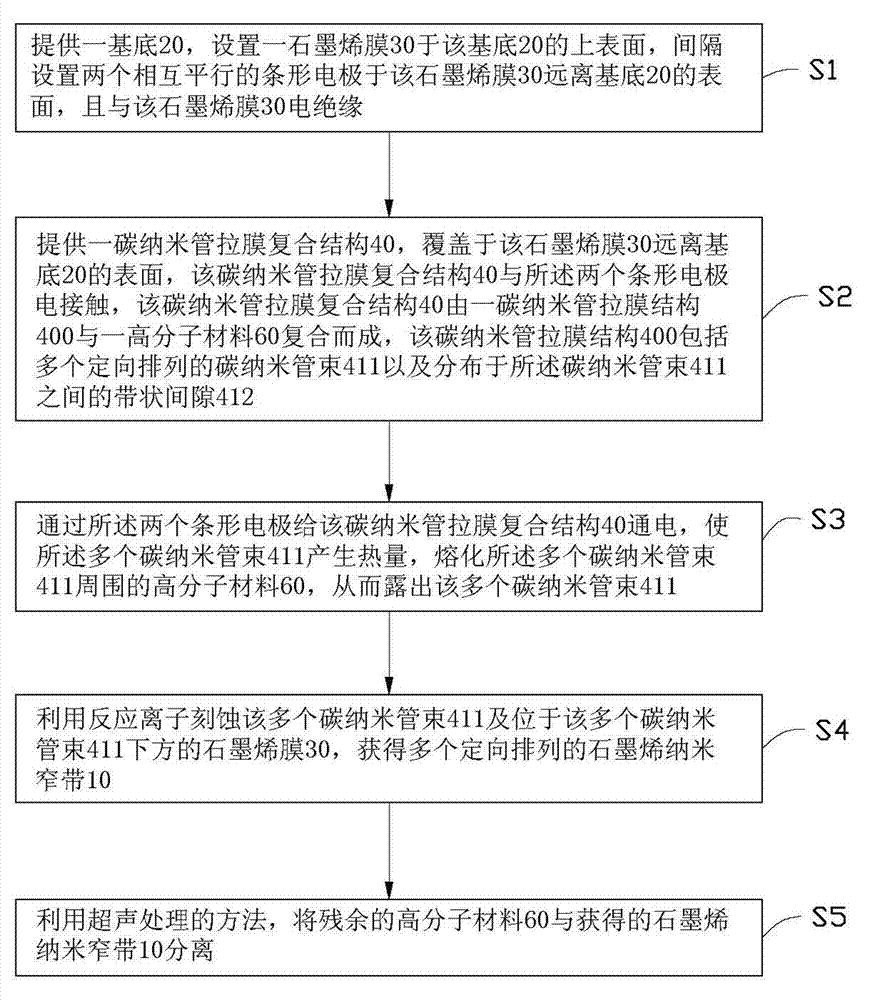

[0019] Please also refer to figure 1 and figure 2 , the embodiment of the present invention provides a kind of preparation method of graphene nano-narrow belt 10, and this method comprises the following steps:

[0020] S1: Provide a substrate 20, arrange a graphene film 30 on the upper surface of the substrate 20, arrange two mutually parallel strip electrodes 50 on the surface of the graphene film 30 away from the substrate 20 at intervals, and connect with the graphene film 30 electrical insulation;

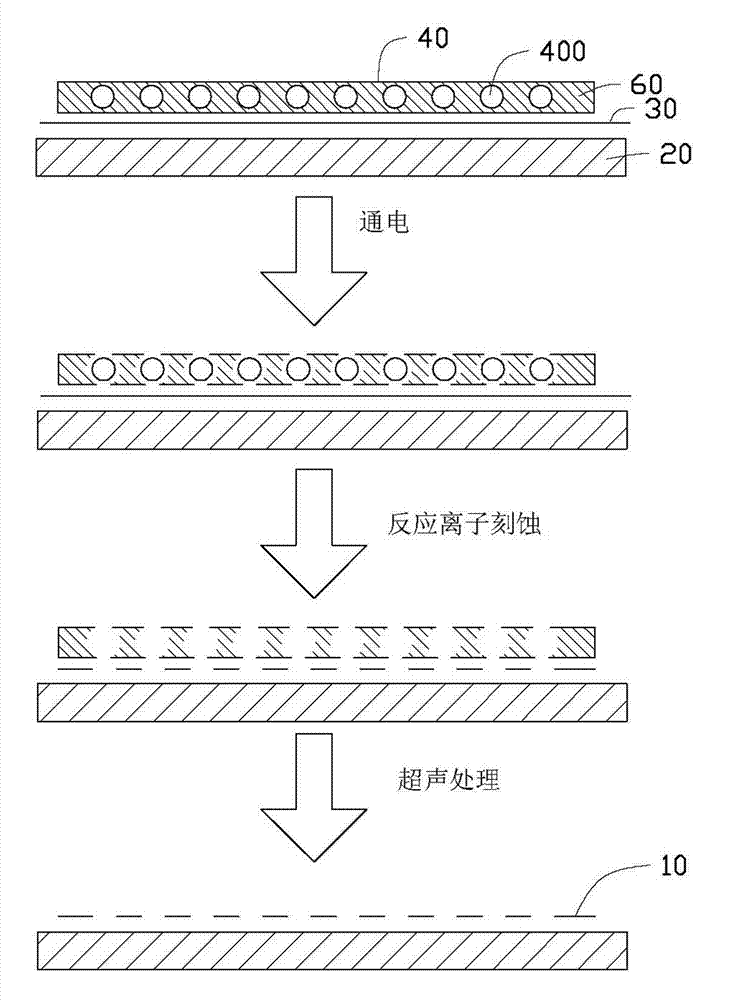

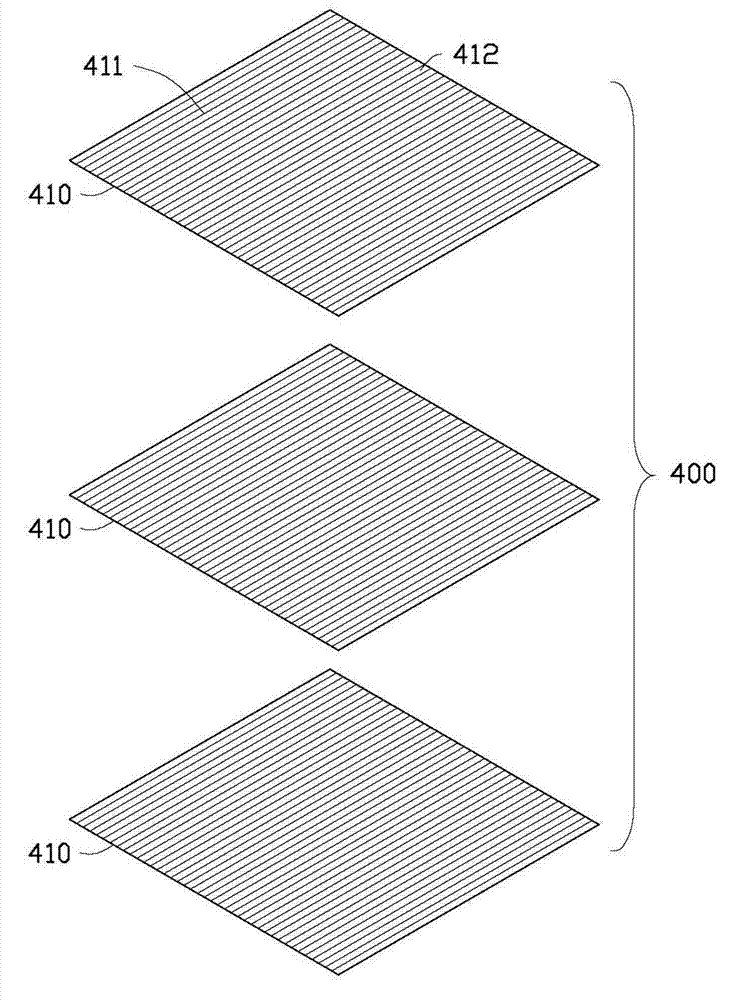

[0021] S2: Provide a carbon nanotube drawn film composite structure 40, covering the surface of the graphene film 30 away from the substrate 20, the carbon nanotube drawn film composite structure 40 is in electrical contact with the two strip electrodes 50, the carbon nanotube The tube-drawn film composite structure 40 is composed of a carbon nanotube drawn film structure 4000 and a polymer material 60. The carbon nanotube drawn film structure 4000 includes a plurality of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com