Nano bone biomimetic material containing tussah silk fibroin, and preparation method thereof

A biomimetic material, tussah silk technology, applied in medical science, prosthesis, etc., can solve the problems of difficulty in dissolving natural tussah silk fibroin, application limitations, etc., and achieve good biocompatibility and biological activity, good strength, and cell affinity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

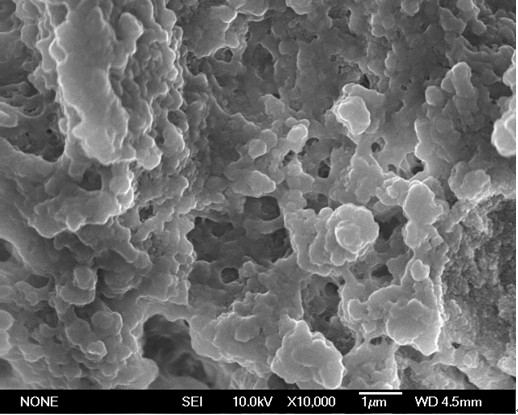

Image

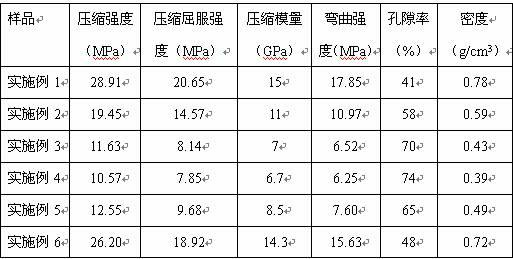

Examples

Embodiment 1

[0019] (1) The cocoons of tussah cocoons are boiled with 1% Na by weight. 2 CO 3 Degumming in the solution for 3 times, bath ratio 1:35, rinsing with hot water 3 times, then drying at 60°C and shredding;

[0020] (2) Put the tussah silk fiber obtained in step (1) into 10 mol / L LiSCN solution at 70°C and dissolve it under high-speed stirring for 100 minutes, with a bath ratio of 1:35. Filter to obtain tussah silk fibroin solution;

[0021] (3) Put the tussah silk fibroin solution obtained in step (2) into a dialysis bag, first place it in clean water for dialysis for 2 days, then place it in distilled water for dialysis for 1 day, change the water every 3 hours, and obtain the weight after dialysis Tussah silk fibroin solution with a concentration of 1%;

[0022] (4) Dissolve CaO in distilled water to obtain 0.05g / mL Ca(OH) 2 Suspension. 1.48L of Ca(OH) 2 suspension and 192.54 g of 85 wt% H 3 PO 4 The solution was dropped into 2.86kg tussah silk fibroin solution obtaine...

Embodiment 2

[0027] (1) The cocoons of tussah cocoons are boiled with 0.5% Na by weight. 2 CO 3 Degumming in the solution for 3 times, bath ratio 1:35, rinsing with hot water 3 times, then drying at 70°C and shredding;

[0028] (2) Put the tussah silk fibers obtained in step (1) into 3 mol / L LiSCN solution at 85°C for 240 minutes with high-speed stirring to dissolve, and the bath ratio is 1:35. Filter to obtain tussah silk fibroin solution;

[0029] (3) Put the tussah silk fibroin solution obtained in step (2) into a dialysis bag, first place it in clean water for dialysis for 2 days, then place it in distilled water for dialysis for 1 day, change the water every 2 hours, and obtain the weight after dialysis Tussah silk fibroin solution with a percentage concentration of 0.5%;

[0030] (4) Dissolve CaO in distilled water to obtain 0.06g / mL Ca(OH) 2 Suspension. 2.467L of Ca(OH) 2 Suspension and 385.1 g of 85 wt% H 3 PO 4 The solution was dropped into 10 kg of the tussah silk fibroin s...

Embodiment 3

[0035] (1) The cocoons of tussah cocoons are boiled with 2% Na by weight. 2 CO 3 Degumming in the solution for 3 times, bath ratio 1:35, rinsing with hot water 3 times, then drying at 50°C and shredding;

[0036] (2) Put the tussah silk fibers obtained in step (1) into 18 mol / L LiSCN solution at 40°C for 35 minutes under high-speed stirring to dissolve, and the bath ratio is 1:35. Filter to obtain tussah silk fibroin solution;

[0037] (3) Put the tussah silk fibroin solution obtained in step (2) into a dialysis bag, put it in clean water for dialysis for 2 days, then place it in distilled water for dialysis for 1 day, change the water every 2.5 hours, and obtain the weight after dialysis Tussah silk fibroin solution with a concentration of 1.5%;

[0038] (4) Dissolve CaO in distilled water to obtain 0.03g / mL Ca(OH) 2 Suspension. 2.467L of Ca(OH) 2 suspension and 192.54 g of 85 wt% H 3 PO 4 The solution was dropped into 2.667 kg of the tussah silk fibroin solution obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com