Ink-jet printing microstructure transduction element and preparation method thereof

A technology of inkjet printing and energy conversion element, which is applied in the direction of offensive equipment, additive manufacturing, fuze, etc., can solve the problems of low material utilization rate, long time consumption, complicated process, etc., and achieves convenient control of bridge film thickness and simple and efficient preparation method , the effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

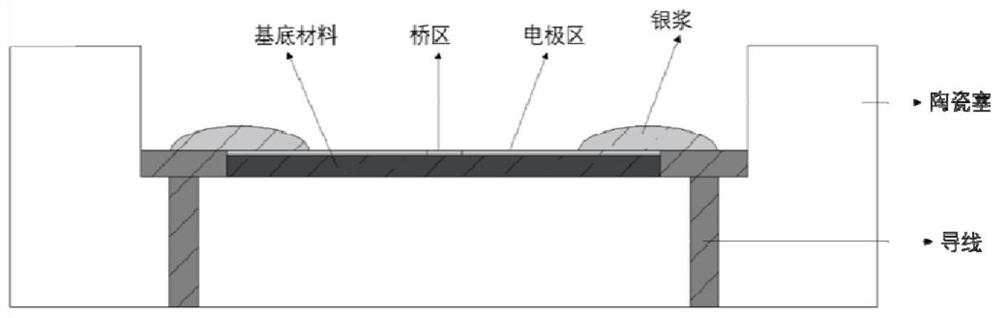

[0032] Inkjet printing to prepare silver film bridge transducers, figure 1 Schematic diagram of the structure of the silver membrane bridge, figure 2 Print patterns for silver film transducers, image 3 It is the physical picture of the silver film bridge and the picture under the microscope of the bridge area. It can be seen from the figure that the surface of the silver film bridge prepared by inkjet printing is uniform, and the pattern formation is in good condition.

[0033] In order to obtain a 1Ω silver film bridge, the number of printing layers is set to 2 layers, and the aspect ratio of the pattern in the bridge area is 1:1.2. The preparation of the silver film transducer element comprises the following steps:

[0034] Step 1: Sonicate the silicon dioxide wafer in deionized water and ethanol liquid for 15 minutes, take it out and dry it;

[0035] Step 2: Put the silicon dioxide wafer into the UV cleaning machine for 15 minutes for surface treatment;

[0036] Step ...

Embodiment 2

[0040] Such as Figure 4 As shown, the printing pattern of the transducer element is a double V shape. In order to design a 0.8Ω silver film bridge, the number of printing layers is set to 2 layers, and the aspect ratio of the pattern in the bridge area is 2:1. The preparation of the silver film transducer element comprises the following steps:

[0041] Step 1: Sonicate the silicon dioxide wafer in deionized water and ethanol liquid for 15 minutes, take it out and dry it;

[0042] Step 2: Put the silicon dioxide wafer into the UV cleaning machine for 15 minutes for surface treatment;

[0043] Step 3: Add nano-silver ink to the printer cartridge, fix the silicon dioxide wafer on the printer substrate, set the heating temperature of the substrate to 55°C, set the inkjet spacing to 25μm, set the temperature of the nozzle to 35°C, and the piezoelectric waveform to be a double wave. The piezoelectric voltage is set at 20V, the number of printing layers is 2 layers, the printing i...

Embodiment 3

[0047] Such as Figure 5 As shown, the printing pattern of the transducer element is "I" font. In order to design a 0.8Ω silver film bridge, the number of printing layers is set to 1 layer, and the aspect ratio of the pattern in the bridge area is 2:1. The preparation of the silver film transducer element comprises the following steps:

[0048] Step 1: Sonicate the silicon dioxide wafer in deionized water and ethanol liquid for 15 minutes, take it out and dry it;

[0049] Step 2: Put the silicon dioxide wafer into the UV cleaning machine for 15 minutes for surface treatment;

[0050] Step 3: Add nano-silver ink to the printer cartridge, fix the silicon dioxide wafer on the printer substrate, set the heating temperature of the substrate to 55°C, set the inkjet spacing to 25μm, set the temperature of the nozzle to 35°C, and the piezoelectric waveform to be a double wave. The piezoelectric voltage is set at 20V, the number of printing layers is 2, and the pre-curing time is 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com