Ultrapure water manufacturing apparatus

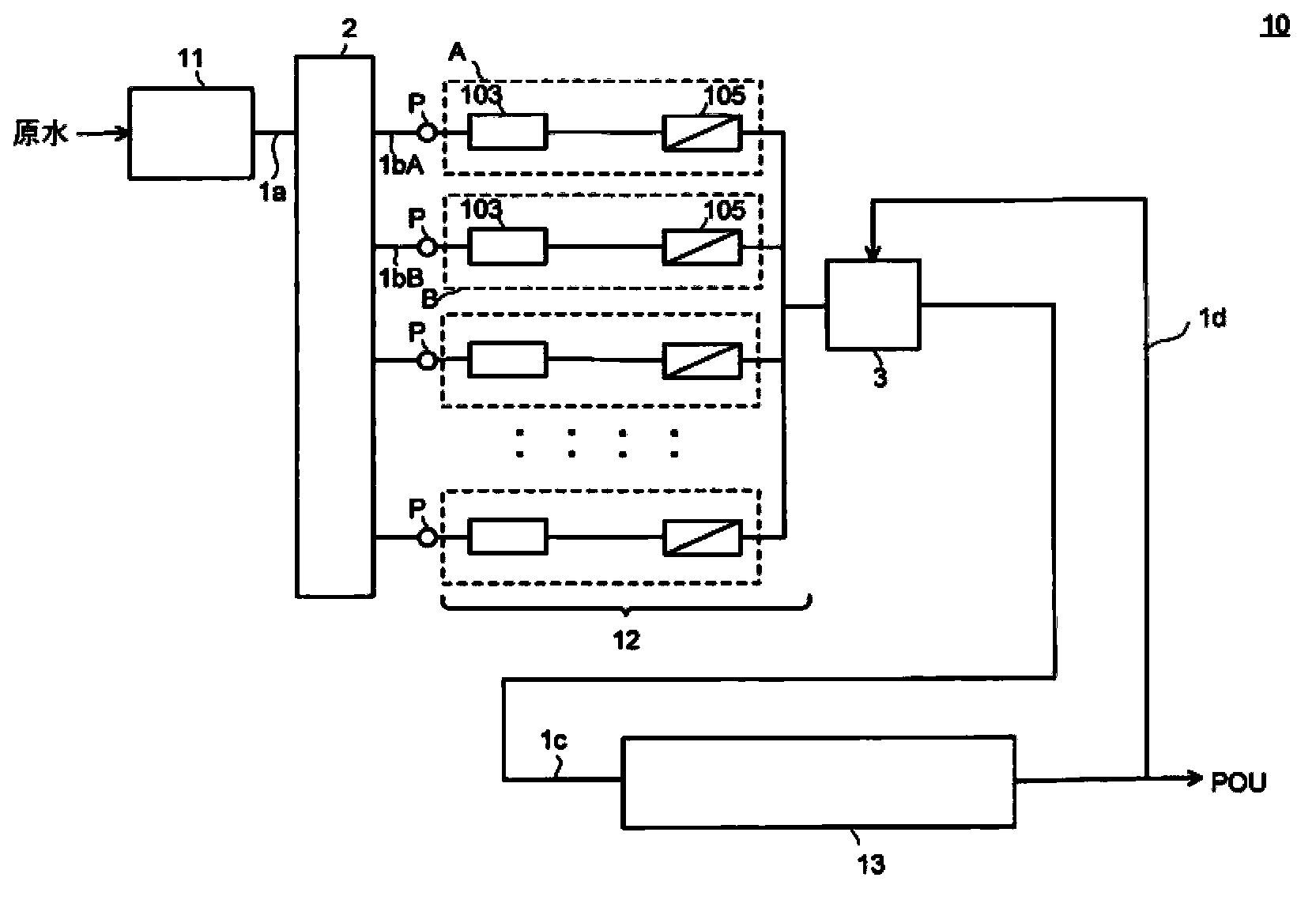

A technology for manufacturing equipment and ultra-pure water, which is applied in water/sewage treatment, non-polluted water treatment, degassed water/sewage treatment, etc. It can solve the problems of increased operating costs and increased nitrogen usage, and achieve flow control Effects of changes, simplification of maintenance management, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Next, ultrapure water was produced using the apparatus of this embodiment and a conventional ultrapure water production apparatus.

[0143] The apparatuses and respective conditions used in Examples and Comparative Examples are as follows.

[0144] Raw water: Atsugi city tap water

[0145] [Pre-processing system 11]

[0146] Microfiltration device 111 : pressurized PVDF MF module UNA-620A, manufactured by Asahi Kasei Chemical Co., Ltd.

[0147] Heat exchanger 112: a plate heat exchanger, made of stainless steel, manufactured by Hisaka Seisakusho Co., Ltd.

[0148] Water storage tank 21: capacity is 1m 3 , made of polyethylene.

[0149] [1 time pure water system 12]

[0150] Activated carbon device 121: Nomura Cartridge Columns NCC-200AC, manufactured by Nomura Micro Science Co., Ltd.

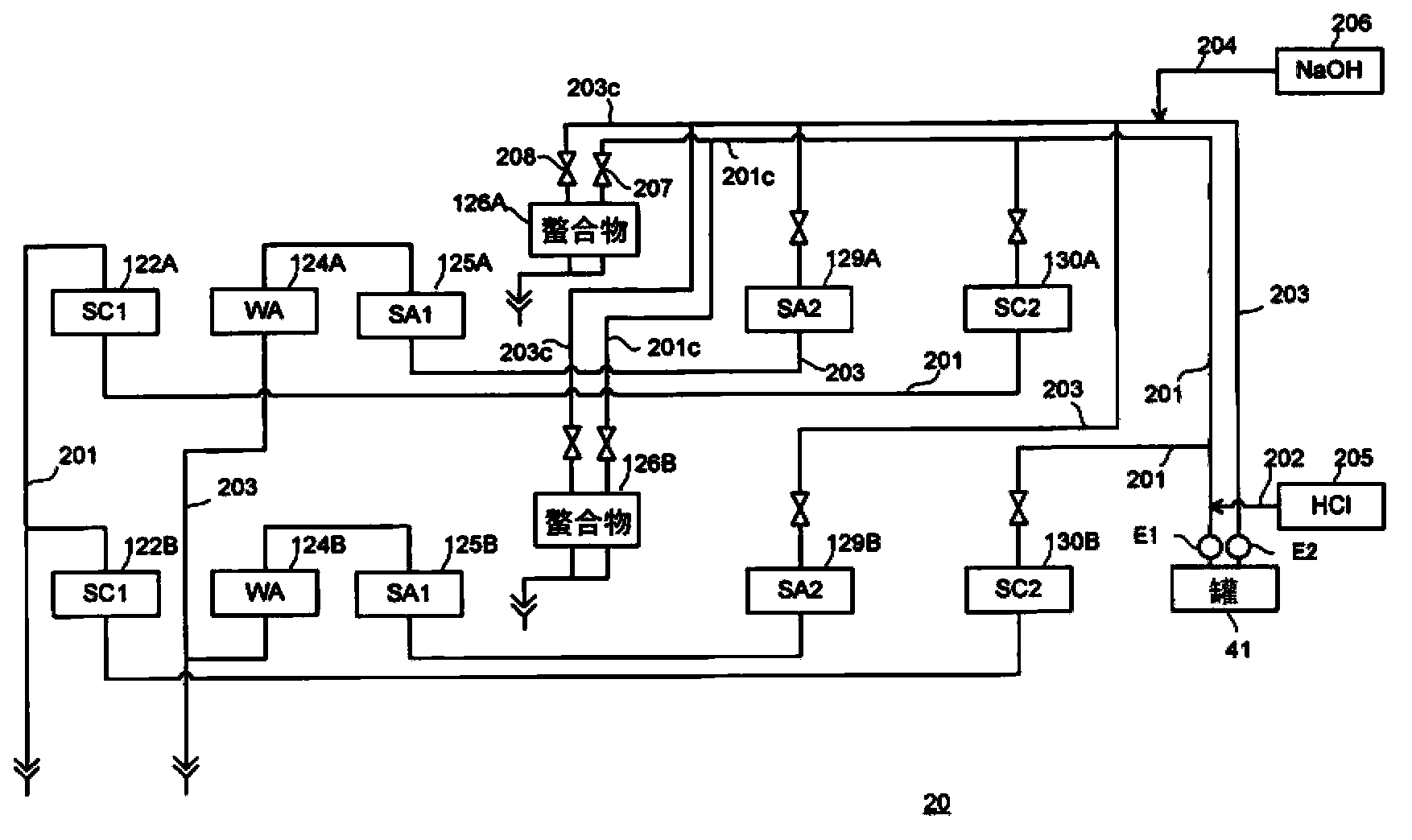

[0151] Strongly acidic cation exchange resin device 122: Duolite C255LFH, the container inner diameter φ is 300 mm, the resin volume is 80 L, manufactured by Dow Chemical Japan Co.,...

Embodiment 1)

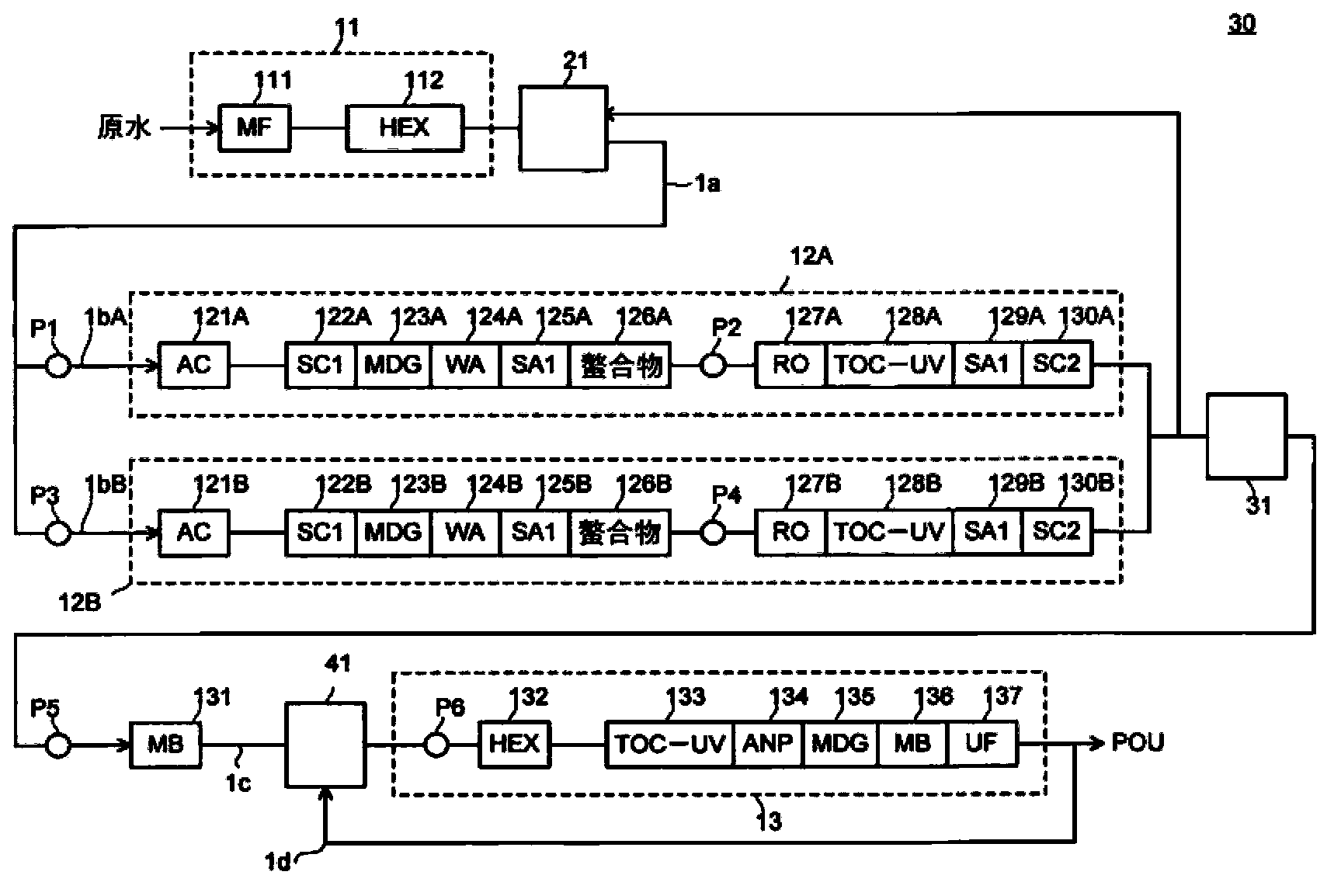

[0187] use image 3 The shown pure water production device 30 produces ultrapure water.

[0188] Such as image 3 As shown, the ultrapure water manufacturing device 30 used in Example 1 includes: a pretreatment system 11 to which a microfiltration device 111 and a heat exchanger 112 are sequentially connected; and a water storage tank 21 at the rear stage of the pretreatment system 11 . The treatment series 12A and the treatment series 12B of the primary pure water system are respectively connected to the water storage tank 21 on the primary pure water lines 1bA and 1bB through the pumps P1 and P3 at the front stage. The pumps P1 and P3 are pumps capable of switching flow paths and changing flow rates. The treatment series 12A starts from the upstream side of the primary pure water line 1bA, and activates the activated carbon device 121A, the strongly acidic cation exchange resin device 122A, the membrane degassing device 123A, the weakly basic anion exchange resin device 12...

Embodiment 2)

[0210] exist image 3 The device uses treatment series A and treatment series B to produce ultrapure water.

[0211]First, switch the pumps P1 and P3 so that the pre-treated water is not passed to the treatment series B, but is treated with the treatment series A. For the devices in the treatment series A and B, those that have been regenerated beforehand were used.

[0212] The flow rate of the produced ultrapure water (at the water outlet of the ultrafiltration device 137) is 1.9m 3 / Hour.

[0213] Based on calculations based on the water quality, flow rate, and amount of resin to be treated, it is estimated that sodium ions leak from the strongly acidic cation exchange resin device 122 24 hours after the water is passed through after the regeneration treatment. Each treatment series switches the pumps P1 and P3 so that the water supply to the treatment series is stopped and the water supply to the other treatment series is started at the same time every 24 hours. While ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com