Nuclear-power concrete air-entraining polycarboxylic acid additive

A polyester polycarboxylic acid and polycarboxylic acid technology, which is applied in the field of concrete, can solve the problems of inability to meet the construction requirements of nuclear power concrete, large concrete slump loss, etc., achieve good compatibility, delay setting time, and improve workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

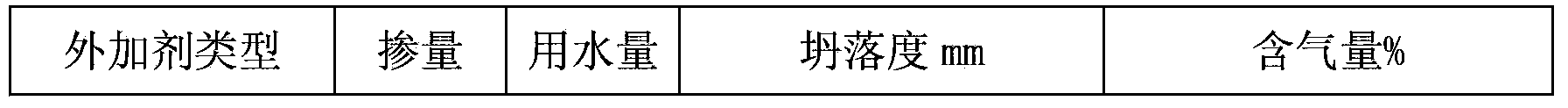

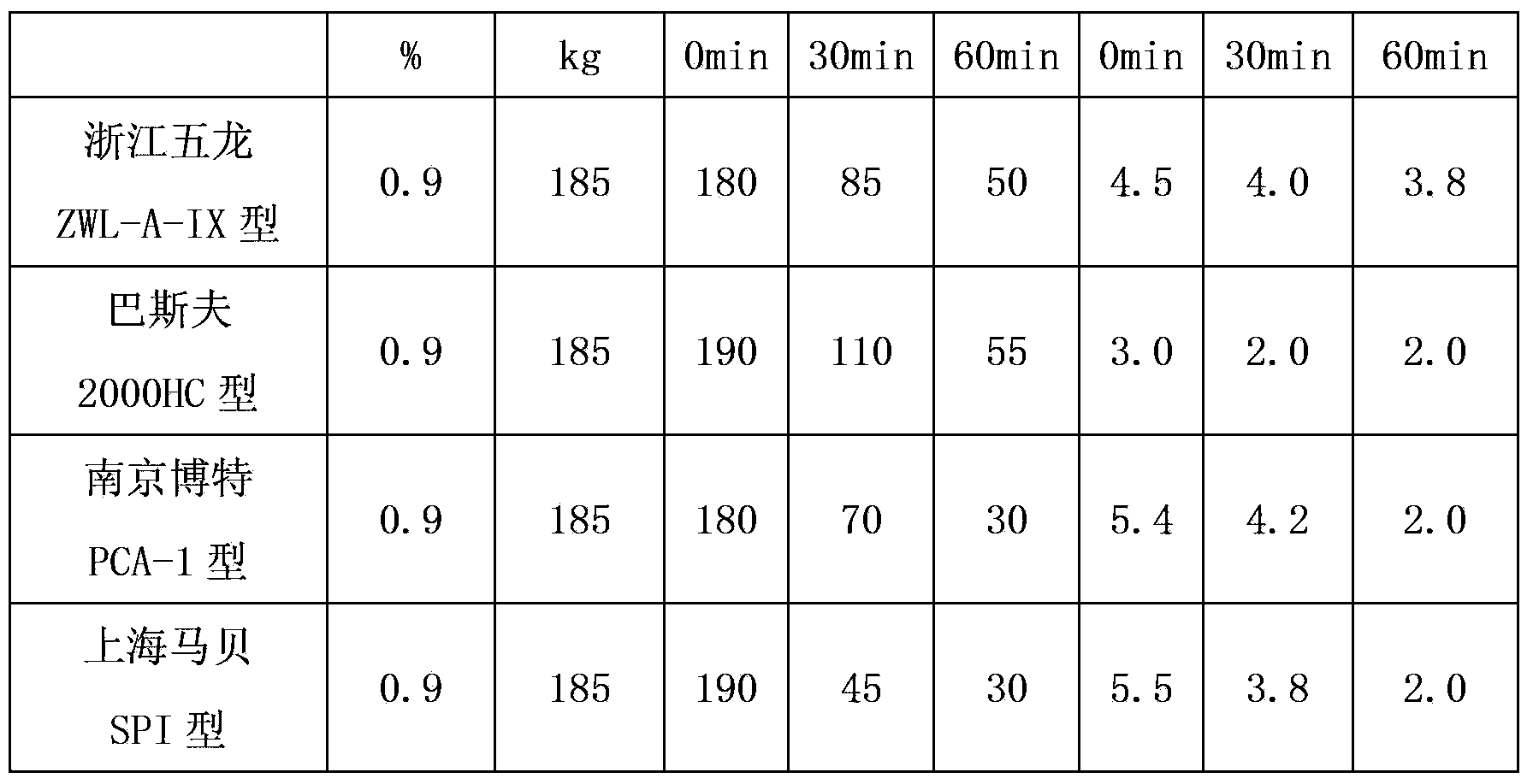

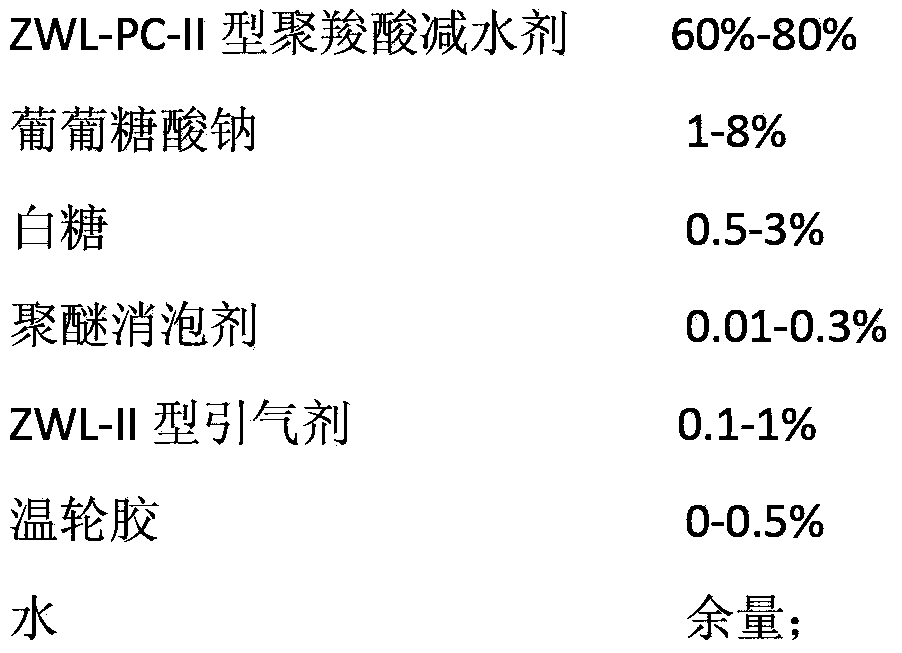

[0036] A concrete air-entraining polycarboxylate admixture for nuclear power, comprising the following substances:

[0037]

[0038] The above-mentioned raw materials are uniformly mixed to obtain the air-entraining polycarboxylic acid admixture for nuclear power concrete of the present invention.

[0039] The above-mentioned ZWL‐II air-entraining agent is made by mixing nonylphenol polyoxyethylene ether and sodium lauryl sulfate at a weight ratio of 1:1.

[0040] The above-mentioned ZWL‐PC‐II polycarboxylate water reducer is formed by mixing polyester polycarboxylic acid and polyether polycarboxylic acid in a weight ratio of 1:0.3.

[0041] Described polyester polycarboxylate adopts following method to prepare from:

[0042] (1) Dehydrate and esterify 0.97mol methacrylic acid and 1mol methoxypolyethylene glycol at 85°C for 3.5 hours under the action of catalytic sulfuric acid. 0.35%;

[0043] (2) Copolymerize 3.6 mol of methacrylic acid with the product obtained in step...

Embodiment 2

[0046] A concrete air-entraining polycarboxylate admixture for nuclear power, comprising the following substances:

[0047]

[0048]

[0049]The above-mentioned raw materials are uniformly mixed to obtain the air-entraining polycarboxylic acid admixture for nuclear power concrete of the present invention.

[0050] The above-mentioned ZWL‐II air-entraining agent is made by mixing nonylphenol polyoxyethylene ether and sodium lauryl sulfate at a weight ratio of 1:1.

[0051] The above-mentioned ZWL‐PC‐II polycarboxylate water reducer is formed by mixing polyester polycarboxylic acid and polyether polycarboxylic acid in a weight ratio of 1:0.3.

[0052] Described polyester polycarboxylate adopts following method to prepare from:

[0053] (1) Dehydrate and esterify 1 mol of methacrylic acid and 1 mol of methoxypolyethylene glycol at 80°C for 3 hours under the action of catalytic sulfuric acid, and the mass of sulfuric acid added accounts for 0.5% of the mass of methoxypolyet...

Embodiment 3

[0057] A concrete air-entraining polycarboxylate admixture for nuclear power, comprising the following substances:

[0058]

[0059] The above-mentioned raw materials are uniformly mixed to obtain the air-entraining polycarboxylic acid admixture for nuclear power concrete of the present invention.

[0060] The above-mentioned ZWL‐II air-entraining agent is made by mixing nonylphenol polyoxyethylene ether and sodium lauryl sulfate at a weight ratio of 1:3.

[0061] The above-mentioned ZWL‐PC‐II polycarboxylate water reducer is formed by mixing polyester polycarboxylic acid and polyether polycarboxylic acid in a weight ratio of 1:0.3.

[0062] Described polyester polycarboxylate adopts following method to prepare from:

[0063] (1) Dehydrate and esterify 0.98mol of acrylic acid and 1mol of methoxypolyethylene glycol under the action of catalyst sulfuric acid at 90°C for 4 hours. The mass of sulfuric acid added accounts for 1% of the mass of methoxypolyethylene glycol ;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com