Method for growing aluminium nitride monocrystal by using physical vapor transport method

A physical vapor transport, aluminum nitride technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve problems such as the inability to obtain large-sized single crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

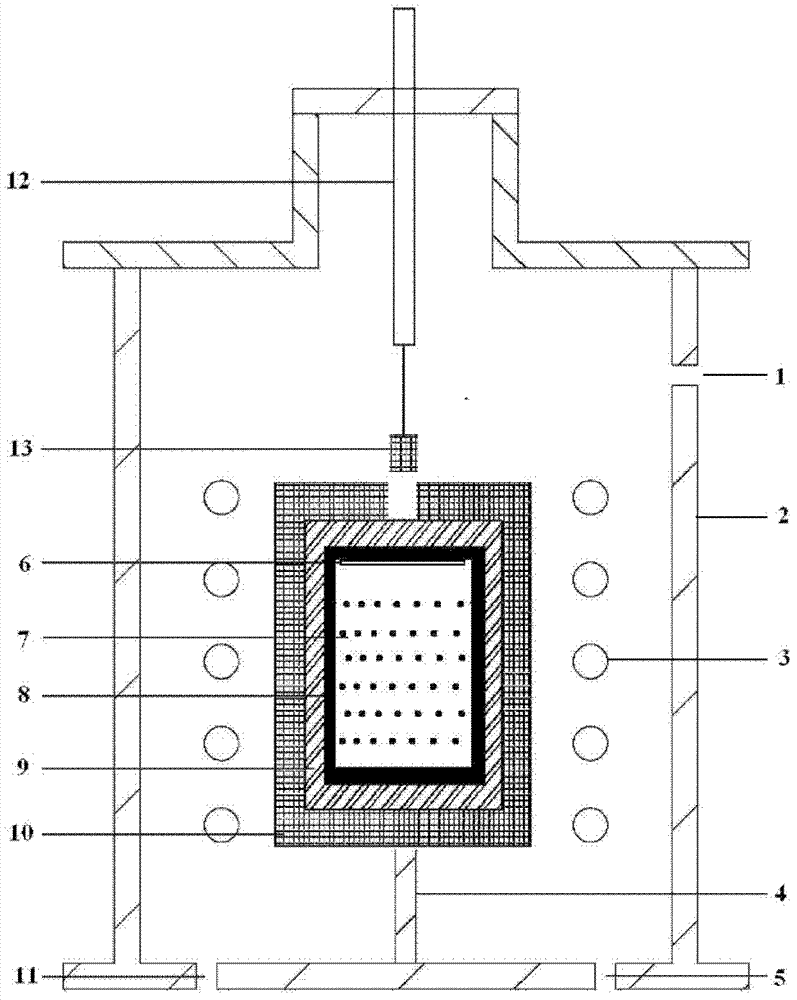

[0033] This embodiment provides a method for growing an aluminum nitride single crystal by using the physical vapor transport method, which includes the following steps:

[0034] 1) Heat the raw material area and the aluminum nitride seed crystal in the equipment for growing aluminum nitride single crystal by the physical vapor transport method, and raise the temperature at a rate of 4°C / min, and keep the temperature of the raw material area and the seed crystal at the same temperature during the heating process , heating up to 2100°C;

[0035] 2) Keep the temperature of the raw material area at 2100°C, and lower the temperature of the seed crystal to 2050°C, at this time, due to the existence of the temperature gradient, the aluminum nitride single crystal begins to grow on the seed crystal;

[0036] 3) heat preservation, keeping the temperature of the raw material area at 2100°C and the temperature of the seed crystal at 2050°C for 6 hours;

[0037] 4) cooling, and taking o...

Embodiment 2

[0041] This embodiment provides a method for growing an aluminum nitride single crystal using a physical vapor transport method, including:

[0042] 1) Heat the raw material area and the aluminum nitride seed crystal in the equipment for growing aluminum nitride single crystal by the physical vapor transport method, and raise the temperature at a rate of 4°C / min, and keep the temperature of the raw material area and the seed crystal at the same temperature during the heating process , heating up to 2300°C;

[0043] 2) Keep the temperature of the raw material area at 2300°C, and lower the temperature of the seed crystal to 2250°C, at this time, due to the existence of the temperature gradient, the aluminum nitride single crystal begins to grow on the seed crystal;

[0044] 3) heat preservation, keeping the temperature of the raw material area at 2300°C and the temperature of the seed crystal at 2250°C for 6 hours;

[0045] 4) cooling, and taking out the grown aluminum nitride ...

Embodiment 3

[0048] This embodiment provides a method for growing an aluminum nitride single crystal using a physical vapor transport method, including:

[0049] 1) Heat the raw material area and the aluminum nitride seed crystal in the equipment for growing aluminum nitride single crystal by the physical vapor transport method, and raise the temperature at a rate of 4°C / min, and keep the temperature of the raw material area and the seed crystal at the same temperature during the heating process , heating up to 2050°C;

[0050] 2) Keep the temperature of the seed crystal at 2050°C, and increase the temperature of the raw material area to 2100°C, at this time, due to the existence of the temperature gradient, the aluminum nitride single crystal begins to grow on the seed crystal;

[0051] 3) heat preservation, keeping the temperature of the raw material area at 2100°C and the temperature of the seed crystal at 2050°C for 6 hours;

[0052] 4) cooling, and taking out the grown aluminum nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com