Melting height control method of ingot casting crystal seed and polycrystalline silicon ingot casting furnace

A polycrystalline silicon ingot furnace, highly controlled technology, applied in chemical instruments and methods, polycrystalline material growth, crystal growth and other directions, can solve the problems of inability to reduce production costs, high-purity quartz rods are expensive, and easy to consume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

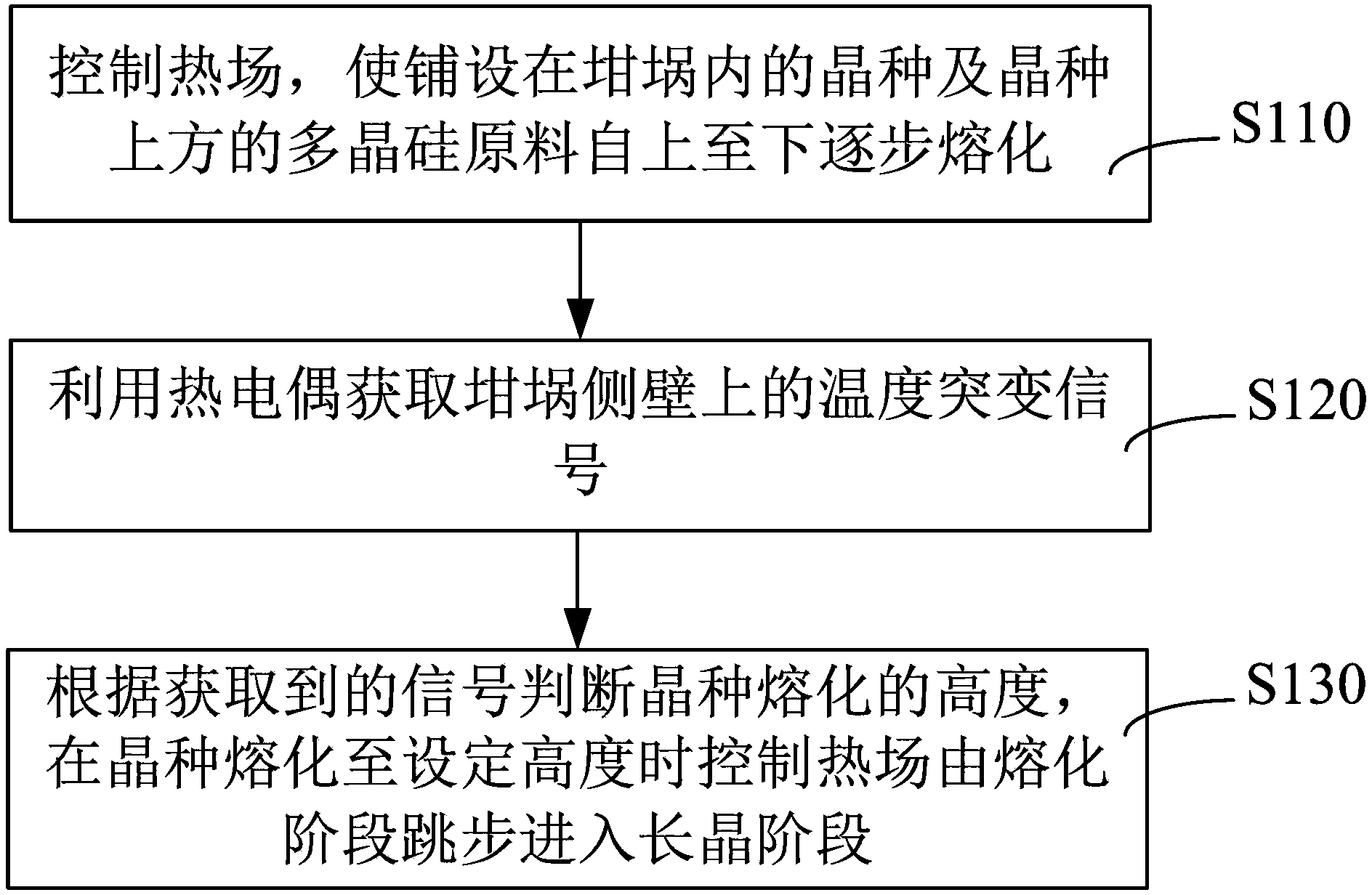

[0022] Please refer to figure 1 , discloses a polysilicon ingot furnace ingot casting seed melting residual height control method, comprising the following steps:

[0023] S110 , controlling the thermal field to gradually melt the polysilicon raw material placed in the crucible and above the seed crystal from top to bottom.

[0024] First, a seed crystal is laid in a crucible, and a polysilicon raw material is laid over the seed crystal. Lay a layer of seed crystal with a certain thickness on the bottom of the crucible, and then fill it with polysilicon raw material normally. The seed crystal can be single crystal seed crystal block, specific polycrystalline silicon circulating material, broken silicon chip, fine particle material, silicon powder material, etc. Then, control the thermal field of the ingot furnace, enter the melting stage, and gradually melt the seed crystal and polysilicon raw materials from top to bottom.

[0025] S120, using a thermocouple to acquire a te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap