Oil drainer for sand control valve

A technology for oil drainage and sand control, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of increasing installation and maintenance workload, etc., and achieve the effect of protecting the environment, ensuring safe operation, and preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

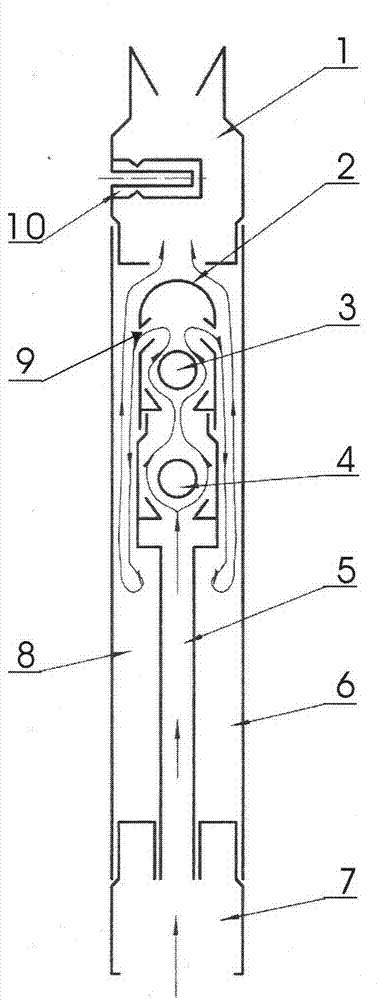

[0011] Combine below figure 1 The present invention is further described:

[0012] When the oil enters the center pipe 5 of the device through the lower joint 7 after the traditional sand removal, the lower ball 3 and the upper ball 4 are pushed away successively under the pressure of the oil flow. It enters into the annular cavity 8 through the downwardly sloped discharge hole 9 provided on the upper ball valve cover 2 . Due to the expansion of the space, the discharged oil immediately diffuses, the flow rate becomes slow, and the buoyancy decreases. The sand and other sundries in the oil that slipped through the first sand control pipe sink into the lower part of the annular cavity of the device. , no longer enters the oil well pump with the oil flow, and the clean oil enters the oil well pump through the upper joint 1 after precipitation.

[0013] When the pump needs to be lifted, the sucker rod and the plunger in the pump are first put out, and then a short rod is put in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com