Multi-passage concrete trolley for weak surrounding rock tunnel benching stepping method construction

A technology for weak surrounding rock and concrete, applied in tunnels, tunnel lining, earthwork drilling and mining, etc., can solve the problem of inability to meet the construction requirements of multi-step tunnels with weak surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

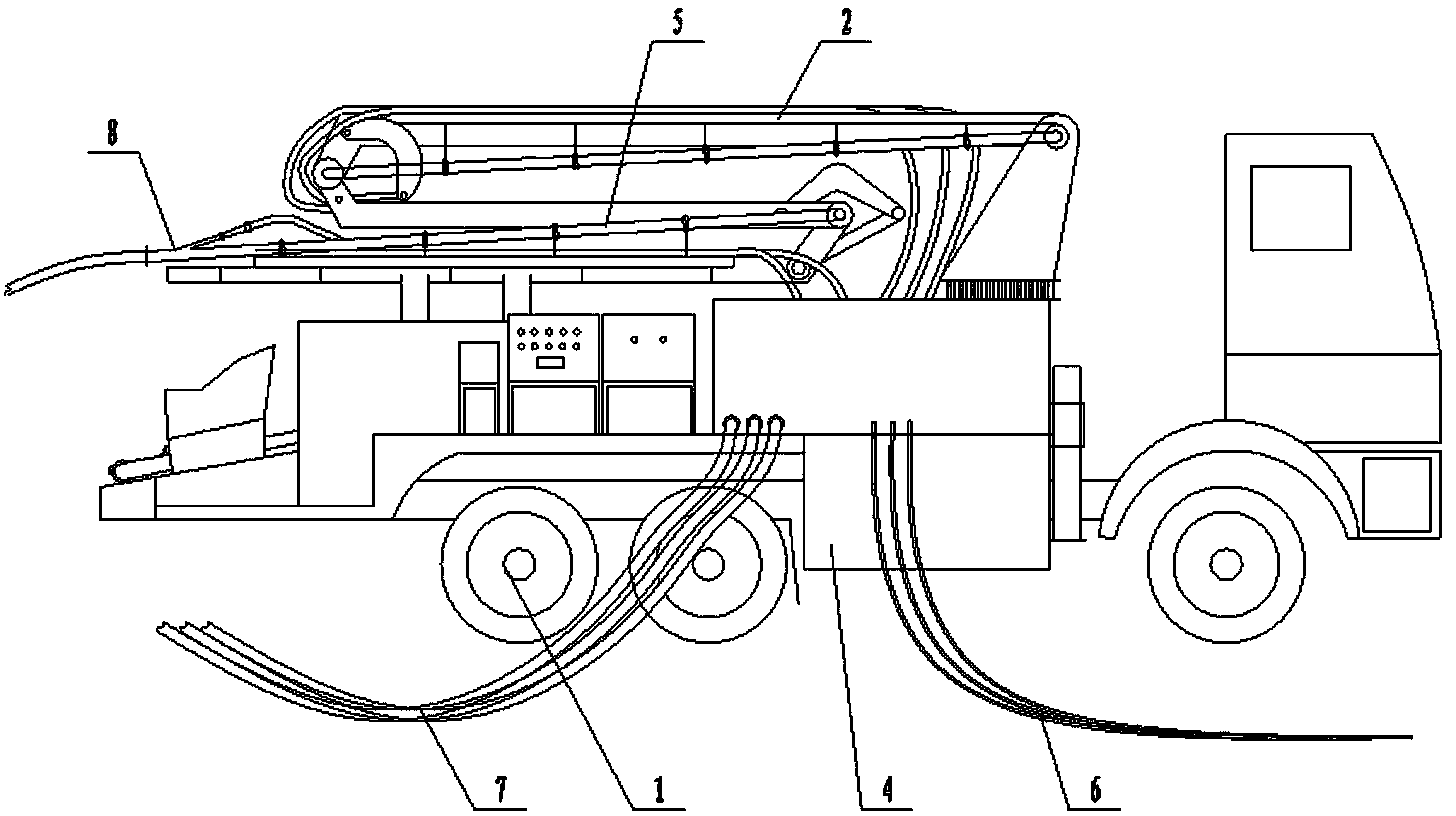

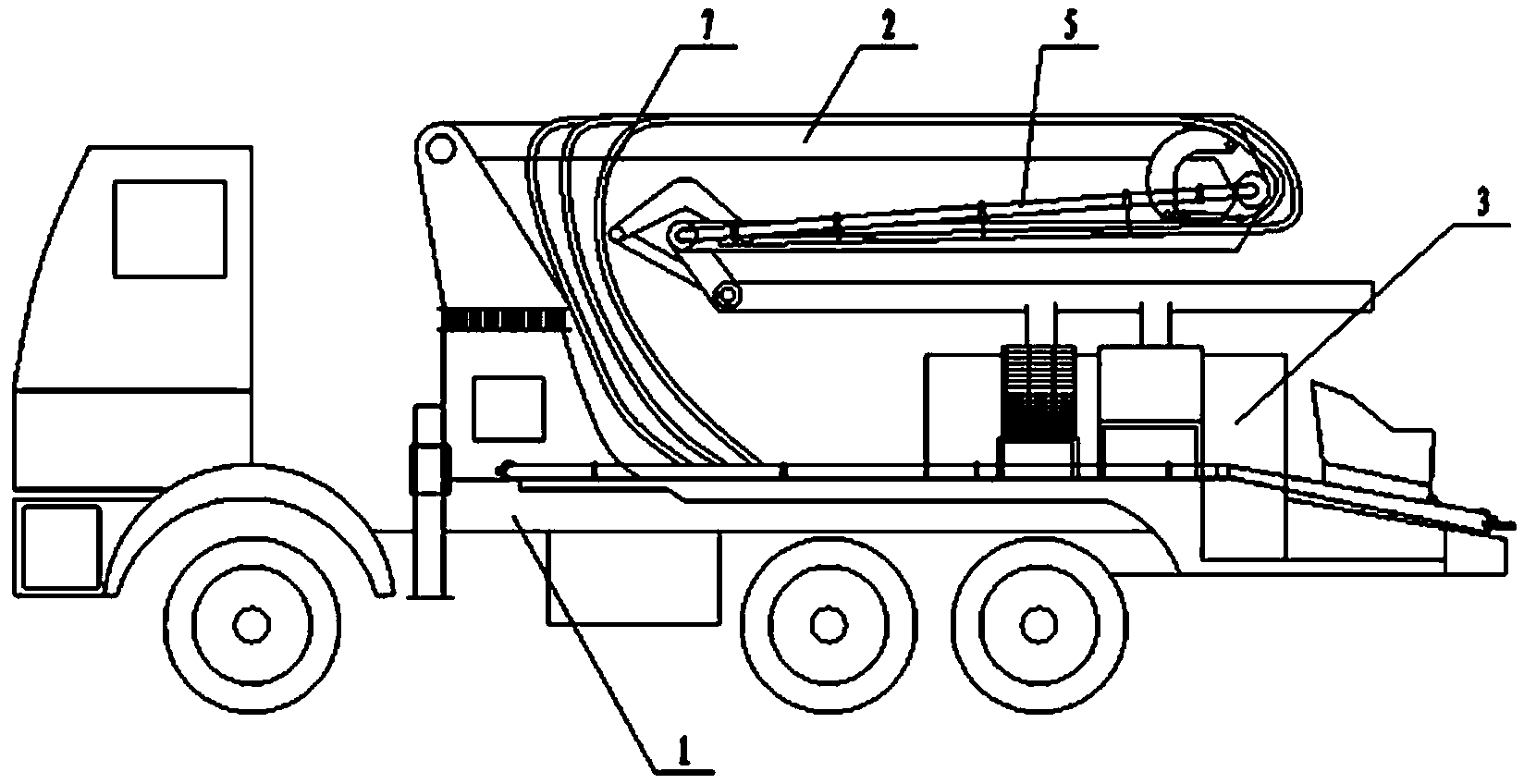

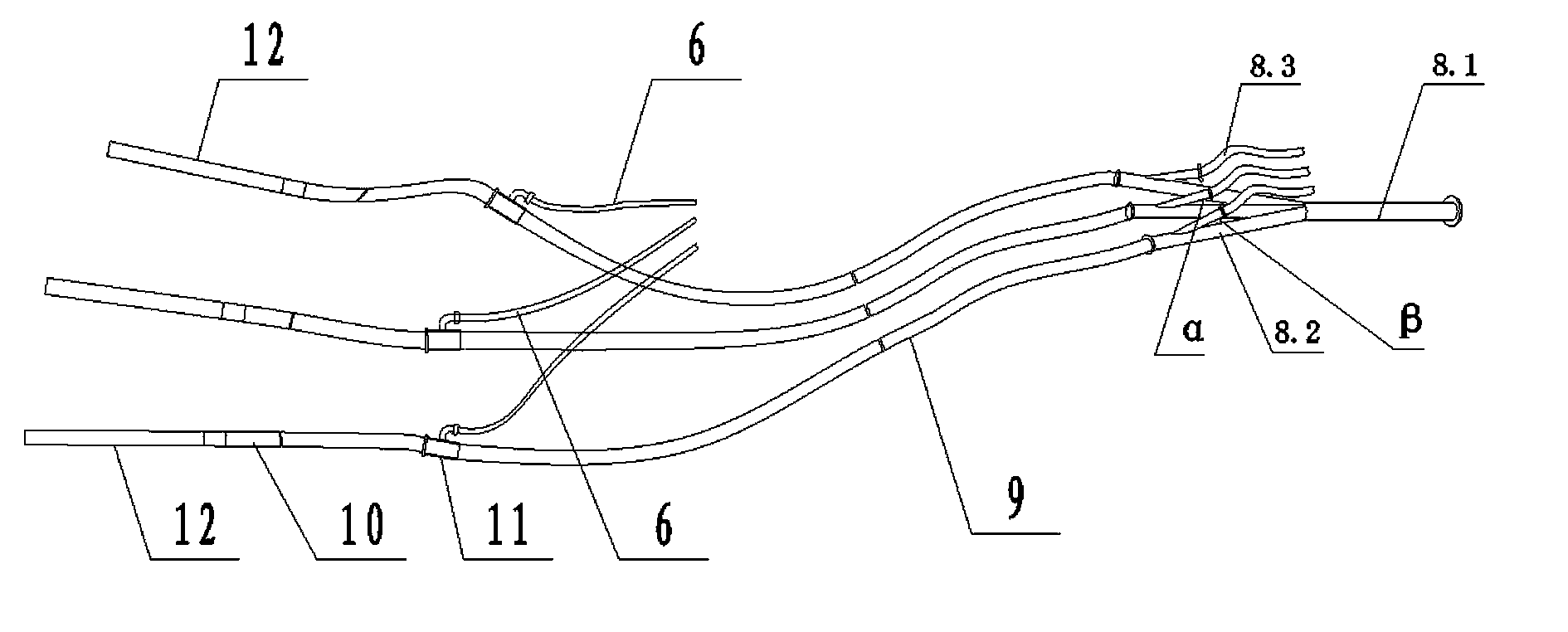

[0018] A multi-channel concrete jumbo for the step method construction of a soft rock tunnel, such as figure 1 , 2 As shown, it includes a car body 1, a folding telescopic boom mounted on the car body 2, a concrete delivery pump 3 and an accelerator pumping system 4, and also includes concrete connected to the concrete delivery pump and arranged on the folding telescopic boom The delivery hard pipe 5, the quick-setting agent delivery pipe 6 connected with the quick-setting agent pumping system, and the high-pressure air delivery pipe 7 arranged on the folding telescopic boom, the quick-setting agent delivery pipe and the high-pressure air delivery pipe are at least Three, the outlet of the concrete conveying rigid pipe is equipped with a multi-channel distributor 8, such as image 3 As shown, the structure of the multi-channel distributor is composed of a main channel 8.1 connected with the outlet of the concrete conveying pipe 5, at least three sub-channels 8.2 connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com