A dustproof thin film assembly frame and a dustproof thin film assembly

A technology of dust-proof film components and frames, which is applied to the original parts, optics, and instruments used for photomechanical processing, and can solve the problems of long flow distance of molten metal, prone to pinholes on the surface, internal defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Hereinafter, examples of the present invention will be described in detail, but the scope of the present invention is not limited to these examples.

[0043] (Example)

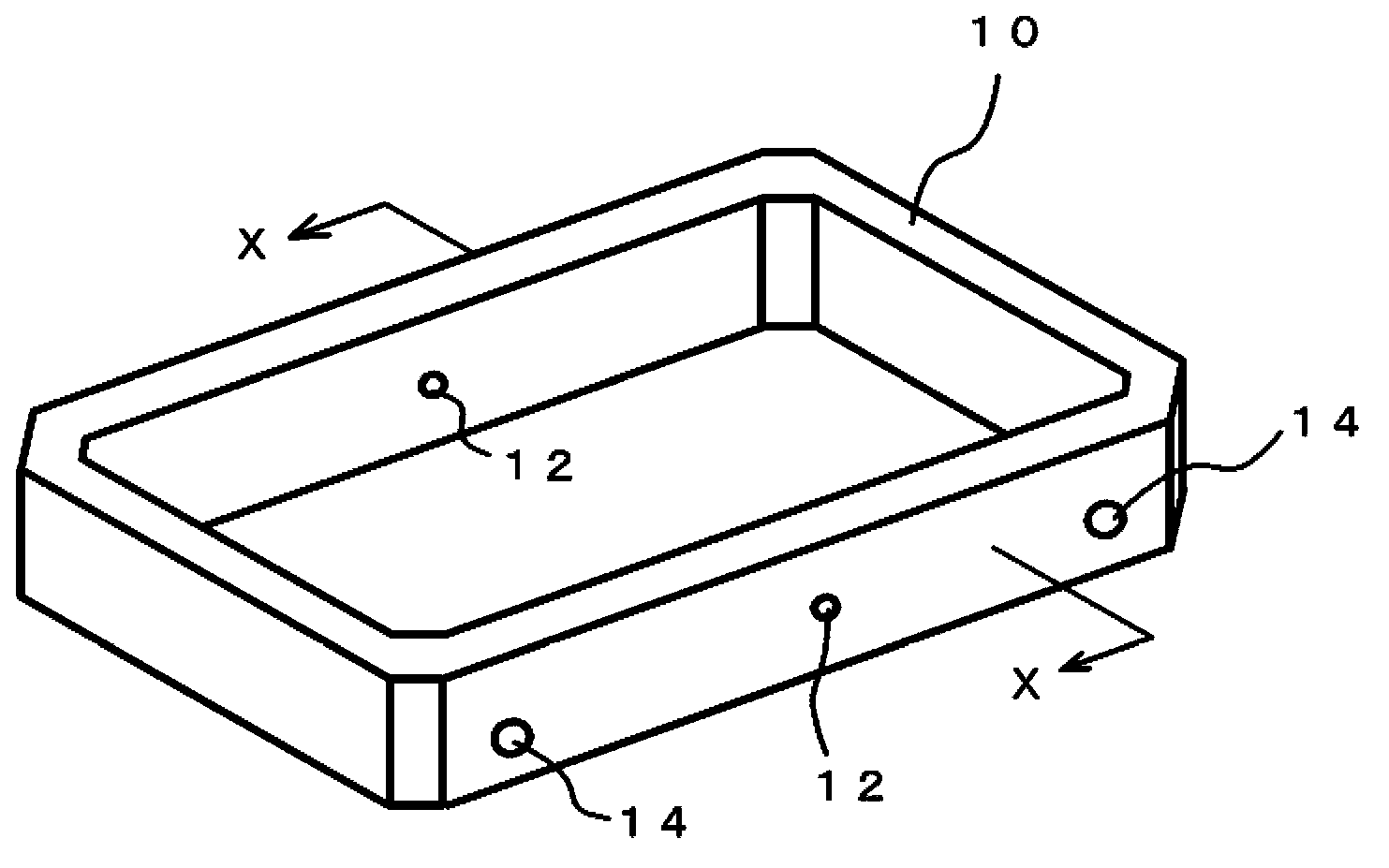

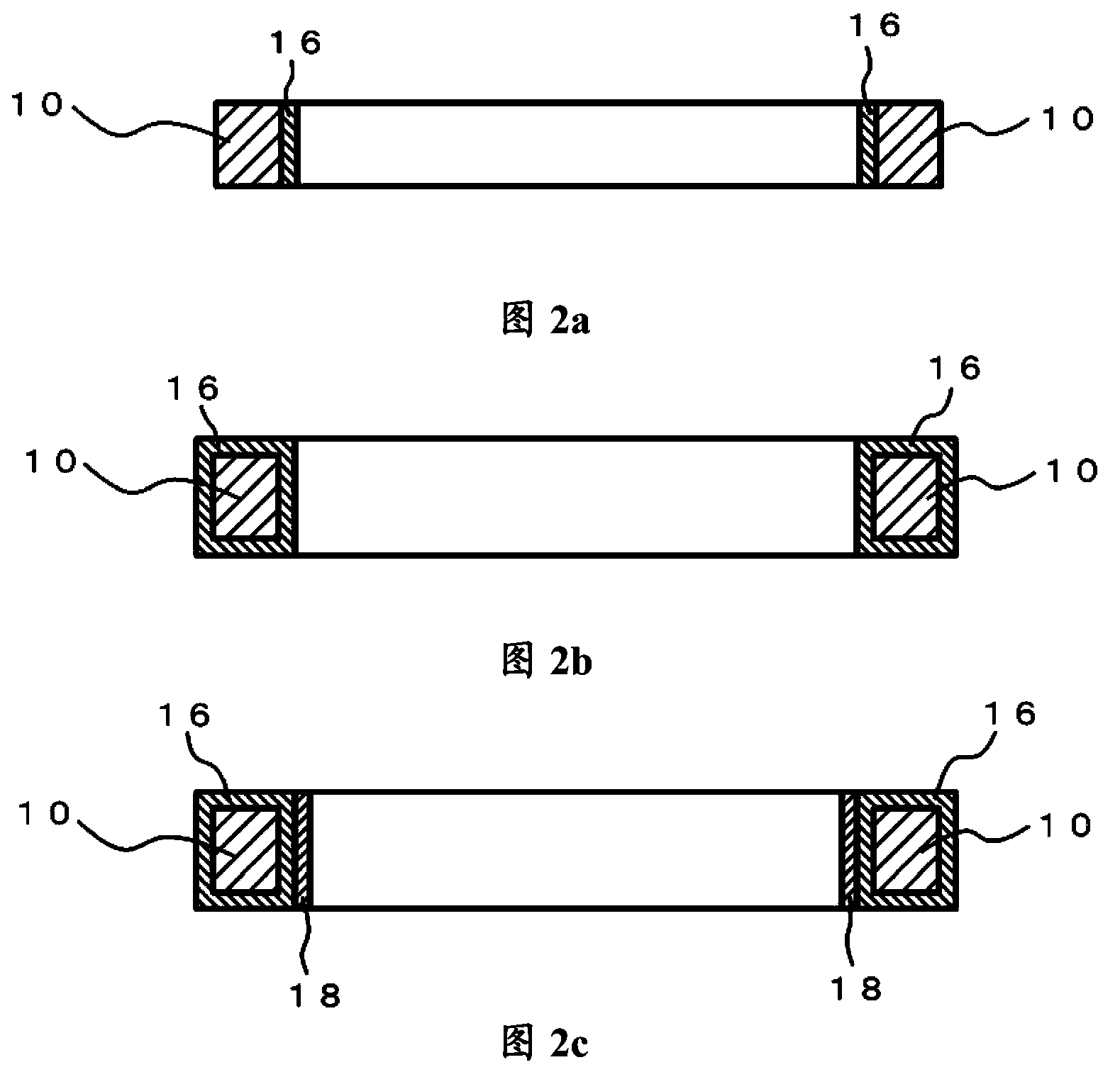

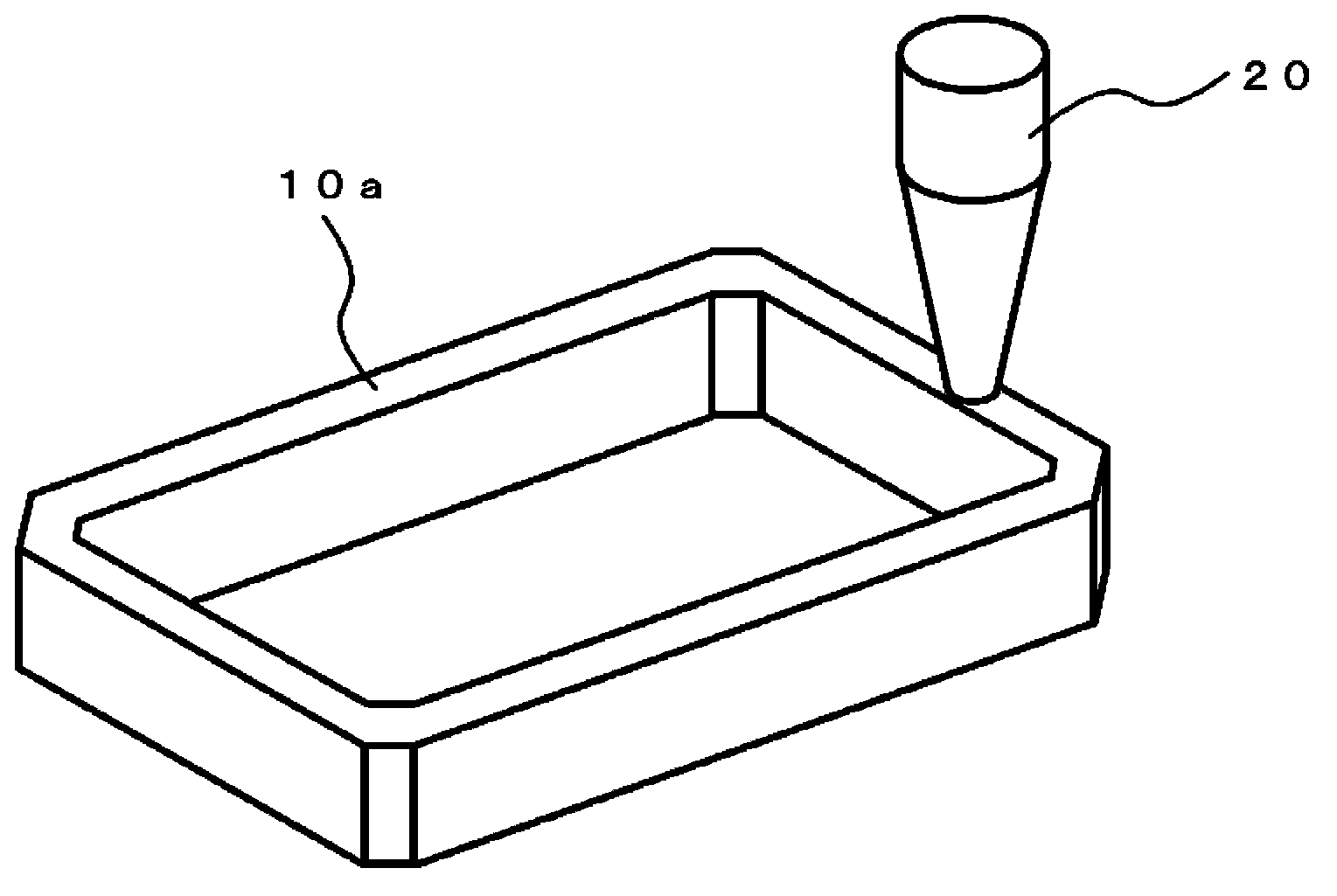

[0044] It was produced by injection molding using a carbon fiber-containing thermoplastic resin (trade name: NXMR-C-40B manufactured by Mitsubishi Rayon Corporation) containing 40% of carbon fibers with a length of 2 to 6 mm and a thickness of 5 to 7 μm in polyamide. figure 1 A rectangular pellicle frame 10 is shown. injection molded and removed from the cooled mold image 3 In the illustrated pellicle frame 10a, a gate portion 20 is formed. With respect to the pellicle frame 10 obtained by cutting the gate part 20, both end surfaces were milled by 0.2 mm with the milling cutter. Then, lightly process the edge of the pellicle frame 10 manually with sandpaper to remove the removal marks of the sprue portion 20 and the burrs on the joint surface of the mold. At this time, the vent holes 12 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com