Organic electroluminescence device and manufacturing method thereof

An electroluminescent device and electroluminescent technology, which are applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of low luminous efficiency of the device, affect the luminous efficiency, light loss, etc., and improve the front luminous intensity. , The effect of improving light extraction efficiency and improving light extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

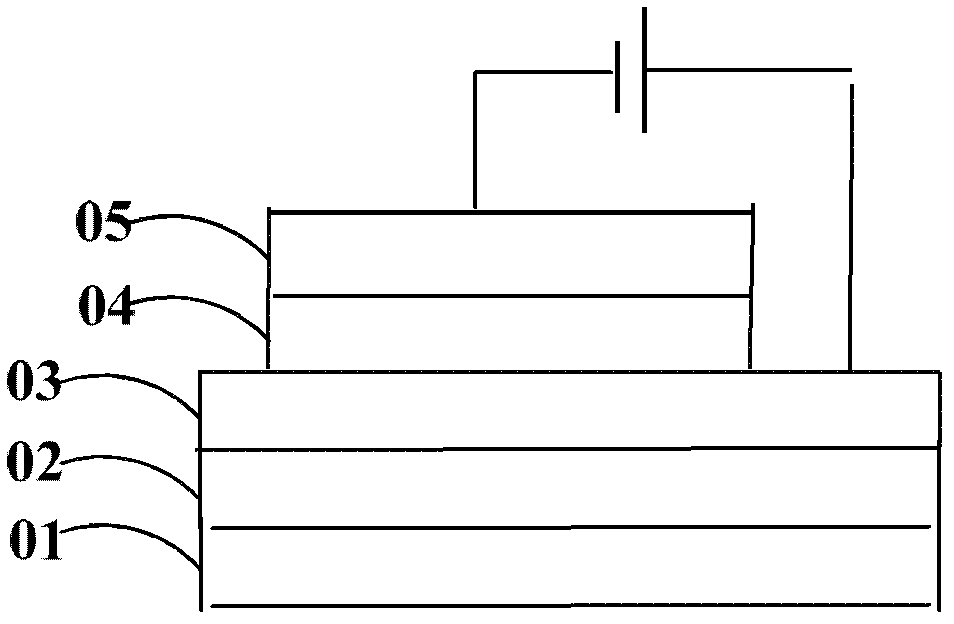

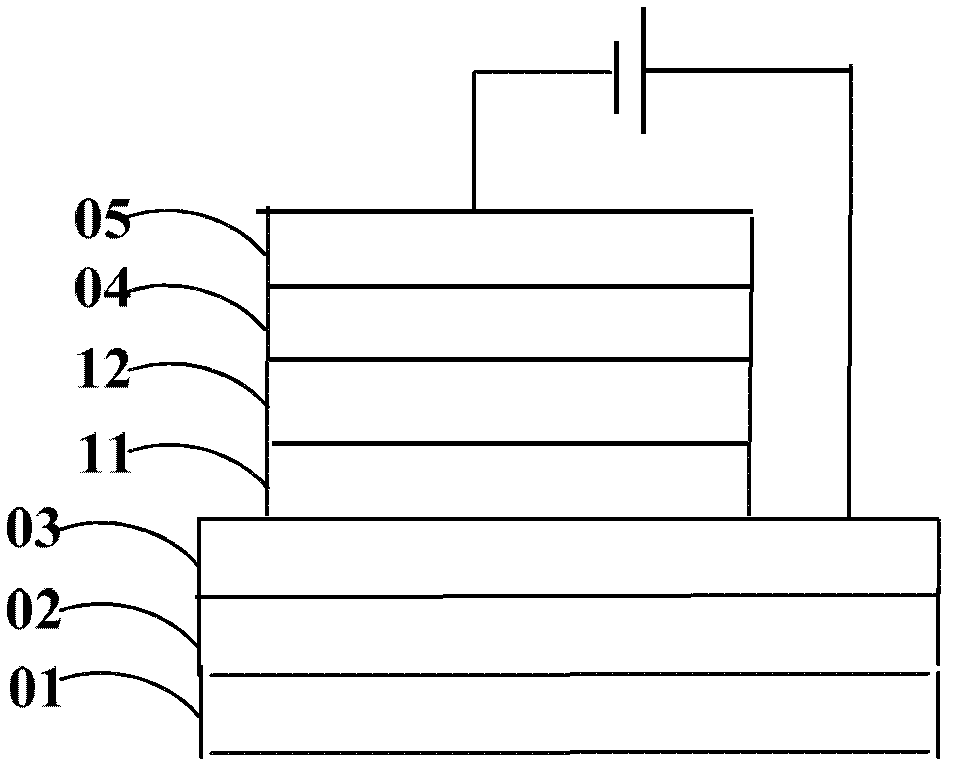

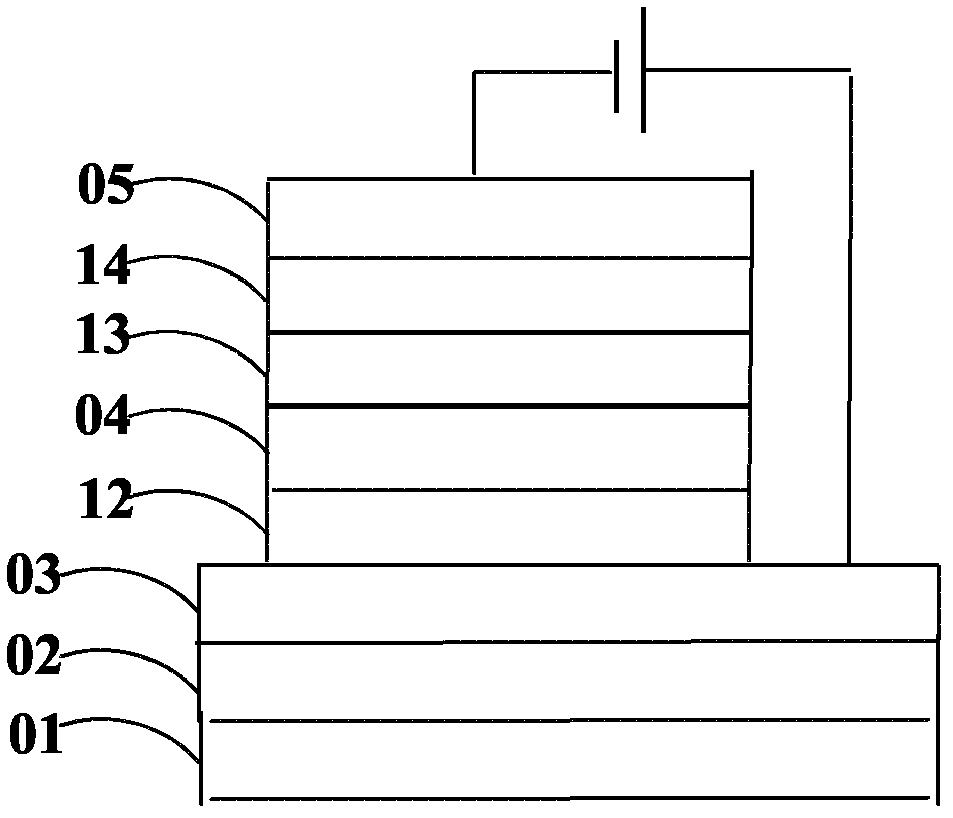

[0035] Another object of the embodiments of the present invention is to provide a method for preparing the above-mentioned organic electroluminescent device, and please refer to Figure 1~4 , which includes the following steps:

[0036] S01: Select a transparent metal oxide with a mass ratio of 0.05-0.6 and a colorless metal compound with a refractive index greater than 2.0, and mix them to obtain a scattering layer material;

[0037] S02: forming a scattering film on the substrate 01 with the scattering layer material to obtain the scattering layer 02;

[0038] S03: sequentially preparing an anode layer 03, a light emitting layer 04 and a cathode layer 05 on the scattering layer 02 to obtain the organic electroluminescence device.

[0039] Specifically, the preferred composition and thickness of each layer of the organic electroluminescent device are as described above, and will not be repeated here to save space.

[0040] In step S01, a 20-200 nm transparent metal oxide an...

Embodiment 1

[0045] First, wash the glass substrate with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface; -4 The doped scattering layer was prepared by vapor deposition under Pa vacuum pressure, and the material was MoO 3 :ZnS, MoO 3 The mass ratio to ZnS is 0.25, and the thickness is 300nm; then the anode conductive film is prepared by magnetron sputtering, the material is ITO, and then the hole injection layer MoO is sequentially evaporated 3 , thickness is 40nm; hole transport layer TCTA, thickness is 50nm; light emitting layer Ir(ppy) 3 Doped TPBi(Ir(ppy) 3 The mass ratio to TPBi is 0.1), the thickness is 20nm; the electron transport layer TAZ, the thickness is 60nm; the electron injection layer is CsN 3 , with a thickness of 1 nm; and a cathode Ag layer, with a thickness of 100 nm; an organic electroluminescent device is obtained.

Embodiment 2

[0047] First, the glass substrate is washed with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface; the doped scattering layer is prepared by evaporation on the glass substrate, and the material is WO 3 : ZnSe, WO 3 The mass ratio to ZnSe is 0.05, and the thickness is 500nm; then the anode conductive film is prepared by magnetron sputtering, the material is IZO, and then the hole injection layer is sequentially evaporated, and the material is V 2 o 5 , with a thickness of 20nm; the hole transport layer NPB, with a thickness of 60nm; the light emitting layer Ir(MDQ) 2 (acac) doped TAZ, Ir(MDQ) 2 The mass ratio of (acac) to TAZ is 0.02, the thickness is 20nm; the electron transport layer TPBi, the thickness is 80nm; the electron injection layer Cs 2 CO 3 , with a thickness of 10nm and a metal cathode Au layer with a thickness of 180nm; an organic electroluminescence device is obtained, and its current efficiency is 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com