Antibacterial agent and preparation method thereof

A technology of antibacterial agent and monoglyceride, applied in the field of antibacterial agent and its preparation, can solve the problems of skin itching, redness, congestion, etc., and achieve the effect of high-efficiency broad-spectrum antibacterial property and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a kind of preparation method of antibacterial agent of the present invention, and this method comprises the following steps:

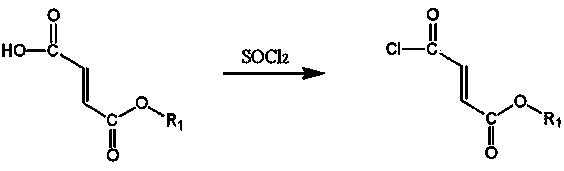

[0022] Preparation of S1, fumaric acid monoester acid chloride

[0023] Add fumaric acid monoester, thionyl chloride and glass beads in the reaction vessel, heat the reaction until the fumaric acid monoester is completely dissolved, and the solution is transparent; continue to keep the temperature at reflux for 30-90min, and finish the reaction to obtain fumaric acid monoester acyl chloride; Concrete reaction equation is as follows:

[0024] .

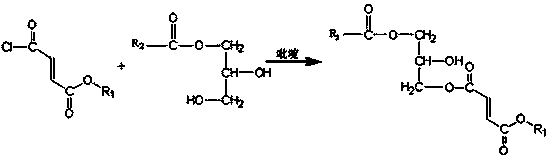

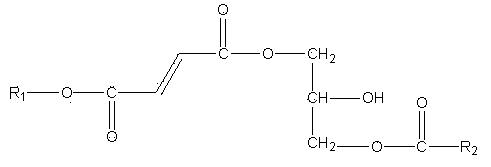

[0025] S2, the preparation of antibacterial agent

[0026] Add monoglyceride and pyridine into the reaction vessel, stir to dissolve; heat to 100-110°C, then slowly add fumaric acid monomethyl chloride to it, and continue to react for 10-60min to obtain the antibacterial agent of the present invention; the specific reaction is as follows :

[0027] .

[0028] ...

Embodiment 1

[0039] 1, the preparation of fumaric acid monoester

[0040] Add maleic anhydride and methanol in a molar ratio of 1:1 in the reaction vessel, keep the temperature at 40°C for 60 minutes, then add the catalyst anhydrous aluminum chloride AlCl -3-- (The addition amount is 6% of the raw material), stir evenly, raise the temperature to 80°C and continue the reaction for 60 minutes to obtain the corresponding white granular fumaric acid monoester.

[0041] 2, the preparation of fumaric acid monoester acid chloride

[0042] In the reaction vessel, add fumaric acid monoester and thionyl chloride SOCl at a molar ratio of 0.9:1 -2 and 3 glass beads, install a reflux device and an exhaust gas absorption device, heat until reflux occurs, and continue the reaction until the fumaric acid monoester is completely dissolved and the solution is transparent. Continue to keep the temperature at reflux for 50min, and finish the reaction to obtain fumaric acid monoester acid chloride.

[0043...

Embodiment 2

[0046] 1, the preparation of fumaric acid monoester acid chloride

[0047] Add commercially available fumaric acid monoester and thionyl chloride SOCl- 2 and 10 glass beads, install a reflux device and an exhaust gas absorption device, heat until reflux occurs, and continue the reaction until the fumaric acid monoester is completely dissolved and the solution is transparent. Continue to keep the temperature at reflux for 30min, and finish the reaction to obtain fumaric acid monoester acyl chloride.

[0048] 2. Preparation of antibacterial agent

[0049] Add glyceryl monostearate and pyridine in the reaction vessel at a molar ratio of 1:1.5, and the molar ratio of fumaric acid monoacyl chloride to monoglyceride is 1.2:1, and stir to dissolve. Heat to 110°C, slowly add fumaric acid monomethyl chloride dropwise, and continue the reaction for 10 minutes. The reaction product is processed through a series of processes to obtain the antibacterial agent A2 as a light yellow block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com