A fracturing fluid system with surface activity after gel breaking

A surface-active, jelly fracturing fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of vegetable glue stability, poor construction performance, and inability to meet deep well and large-scale fracturing construction, etc. Achieve the effects of strong flowback ability, good rheology, and excellent reservoir protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

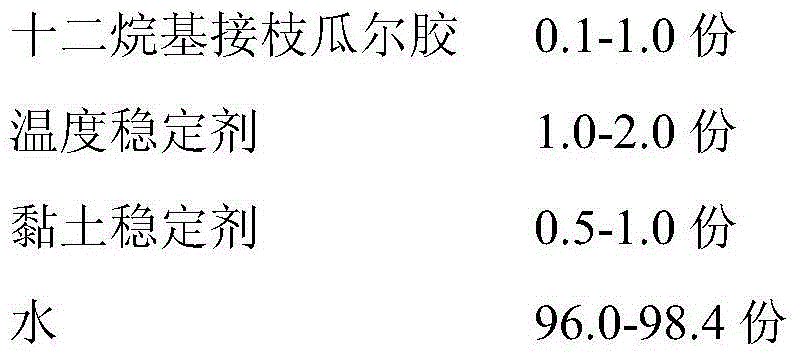

[0027] Add 96.0 parts of clear water by weight in the field container, then slowly add 1.0 parts of dodecyl grafted guar gum under the condition of pump circulation, then add 1.0 parts of clay stabilizer KCl and 2.0 parts of temperature stabilizer triethanolamine, Continue to cycle for 10 minutes. Continue to circulate and top up with liquid for 20 minutes to ensure that the liquid is well mixed to form Solution A.

[0028] Just before construction, pour 2.0 parts of cross-linking agent by weight into a container filled with 97.9 parts of clear water and add 0.1 part of gel breaker potassium persulfate as solution B.

[0029] During fracturing construction, while pumping solution A, mix solution B according to the volume ratio of A:B=100:1.2 to form jelly fracturing fluid.

Embodiment 2

[0031] Add 98.4 parts of clear water by weight to the on-site container, then slowly add 0.01 part of dodecyl grafted guar gum under the condition of pump circulation, and then add 1.0 part of clay stabilizer KCl according to the formula ratio, and continue to circulate for 10 minutes. Continue to circulate and top up the fluid for 20 minutes to ensure the fluid is well mixed for a slick water fracturing fluid.

Embodiment 3

[0033] Prepare slick water fracturing fluid according to the following proportions:

[0034] Lauryl grafted guar gum 0.15 parts

[0035] NH 4 Cl 0.5 parts

[0036] 96.0 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com