Special-shaped dual functional coupling agent-assisted PEG (polyethylene glycol) modifying method for protein

A bifunctional linker and modification method technology, applied in the field of protein chemistry, can solve the problems of unfavorable production control stability and high yield of PEG multi-modification, and achieve the effect of separation and purification and high yield of single modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

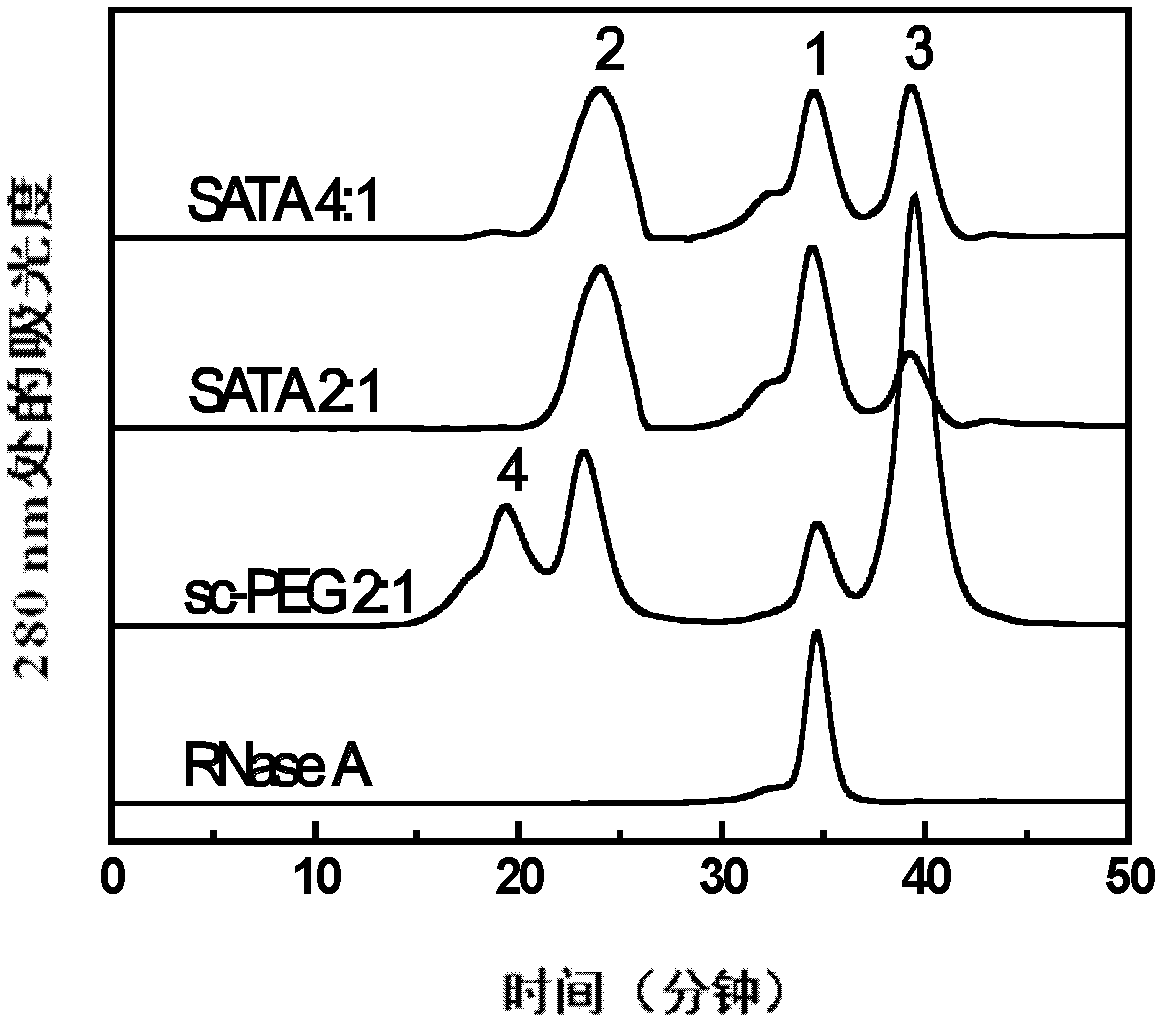

[0029] Embodiment 1SATA assists the PEG modification of RNaseA

[0030] experimental method

[0031] RNaseA was dissolved in 20 mM phosphate buffer solution (pH 7.4). SATA was first dissolved in N,N-dimethylformamide, and then a certain amount of 20mM phosphate buffer (pH 7.4) was added. According to the molar ratio of RNase A and SATA being 1:2 and 1:4, a certain amount of SATA solution was added to the RNaseA solution respectively, shaken and mixed, and left to stand at 4° C. for 3 hours to react.

[0032] Hydroxylamine was dissolved in 20 mM phosphate buffer (pH 7.4), and a certain amount of hydroxylamine solution was added to the mixture of RNaseA and SATA according to the molar ratio of RNaseA and hydroxylamine at a ratio of 1:20. After shaking, let stand at 4°C for 2 hours to react.

[0033] The reaction solution was transferred to an ultrafiltration tube with a molecular weight cut-off of 5kDa, and the centrifugation speed was set to 5000g to remove unreacted SATA, h...

Embodiment 2

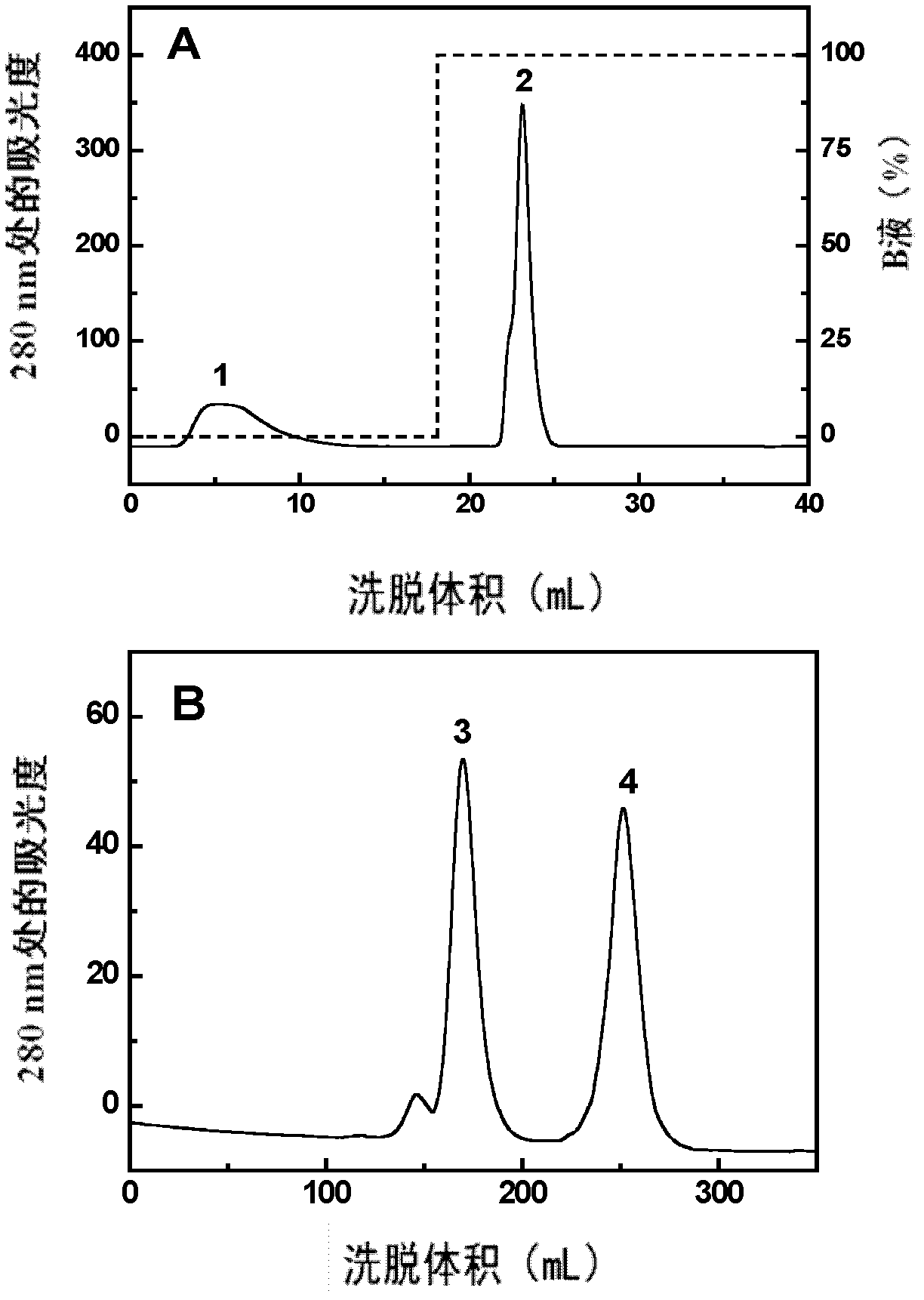

[0038] The separation, purification and identification of embodiment 2PEG single modification product

[0039] experimental method

[0040] By means of dialysis, the above sample solution was replaced into 50 mM acetic acid-sodium acetate buffer solution (pH5.0, solution A). Using SP Sepharose High Performance cation exchange chromatography, the unreacted PEG in the sample was eluted with liquid A after loading the sample, and then 100% pH 5.0 was used, and 0.5M sodium chloride was added to the acetic acid-sodium acetate buffer solution ( Solution B) Elution of protein components. The eluted protein fractions were collected.

[0041] The PEG single-modified product of RNase A was separated and purified with a preparative chromatographic column Superdex 200 (2.6cm×70cm). The buffer system used was PBS buffer (pH 7.4), and the product was collected and concentrated.

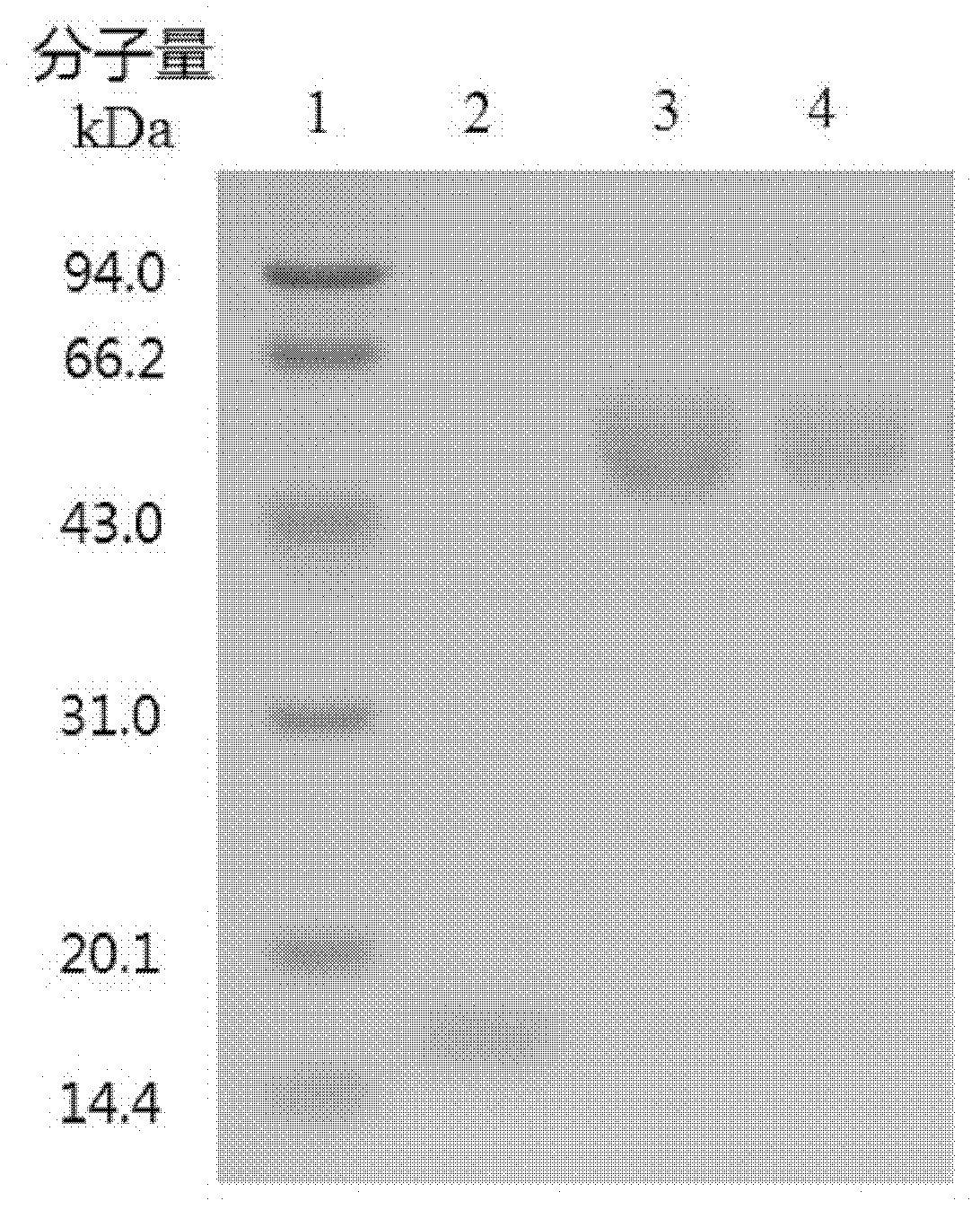

[0042] The purified samples were identified by reducing SDS-PAGE. Using PolyA-PolyU sodium salt as the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com