A kind of preparation method of single crystal trimanganese tetraoxide

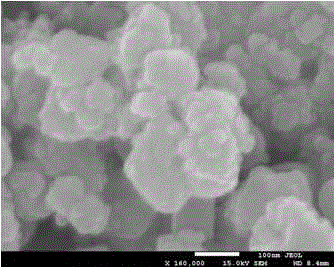

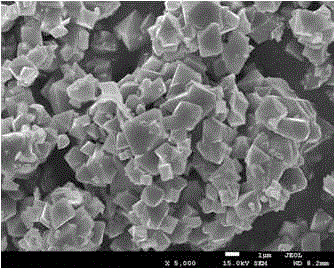

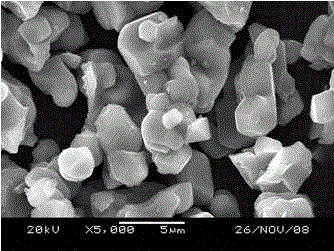

A technology of manganese tetroxide and manganese tetroxide seed crystal, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problem of easy agglomeration of particles, and achieve the effect of complete crystal shape and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a single crystal Mn 3 o 4 The preparation method comprises the following steps:

[0018] S1. Add the water-soluble manganese compound to the basic compound to react to obtain manganese hydroxide; the OH in the basic compound - and Mn in water-soluble manganese compounds 2+ The molar ratio is 2-7;

[0019] S2, the manganese hydroxide obtained in step S1 is oxidized to Mn 3 o 4 ;

[0020] S3, the Mn that step S2 obtains under the inert atmosphere 3 o 4 Ripe to get Mn 3 o 4 seed crystal;

[0021] S4, Mn obtained in S3 3 o 4 In the presence of seed crystals, oxidation proceeds simultaneously with the reaction of water-soluble manganese compounds with basic compounds, Mn 3 o 4 The seed crystal grows up to obtain the single crystal Mn 3 o 4 .

[0022] Single crystal Mn provided by the invention 3 o 4 In the preparation method, in OH - Manganese hydroxide obtained under excess conditions (that is, adding water-soluble manganese compou...

Embodiment 1

[0038] (1) Synthesis of manganese hydroxide

[0039] In a three-necked flask, add 14g of NaOH solution and 70ml of water, stir to dissolve, and vent the air with nitrogen for 15min; put 8.45g of MnSO 4 ·H 2 O was dissolved in 30ml of water, configured as a manganese sulfate solution, and added dropwise to the above NaOH solution under stirring conditions, and the dripping was completed in 30 minutes (OH - with Mn 2+ The molar ratio is 7); the solution was heated to 90°C and kept for 1h.

[0040] (2) Mn 3 o 4 Synthesis

[0041] Under stirring conditions, air was introduced into the product system of step (1), and oxidized at 90°C for 8 hours to obtain Mn 3 o 4 The product system is denoted as sample A.

[0042] (3) Mn 3 o 4 maturation (i.e. synthesis of seed crystals)

[0043] Mn to step (2) 3 o 4 Nitrogen was introduced into the product system, and kept at 90°C for 8 hours to obtain Mn 3 o 4 Seed system.

[0044] (4) Growth of seed crystal

[0045] Keep the Mn...

Embodiment 2

[0047] Using the same steps as in Example 1 to prepare the single crystal Mn of this example 3 o 4 Sample S20, the difference is: after completing step (4), continue to repeat step (4) to obtain the single crystal Mn 3 o 4 Sample, denoted as S20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com