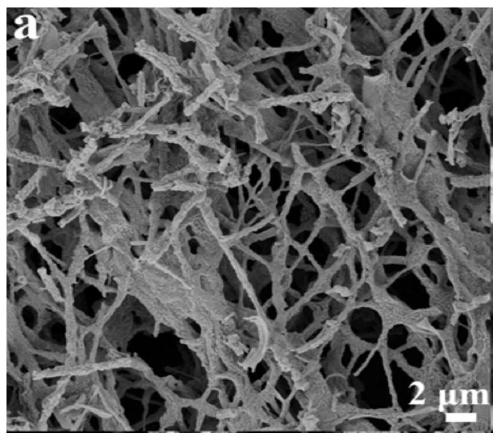

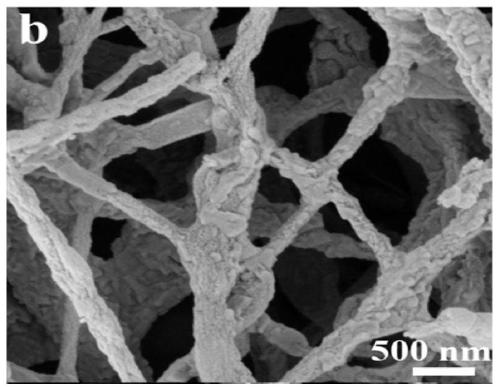

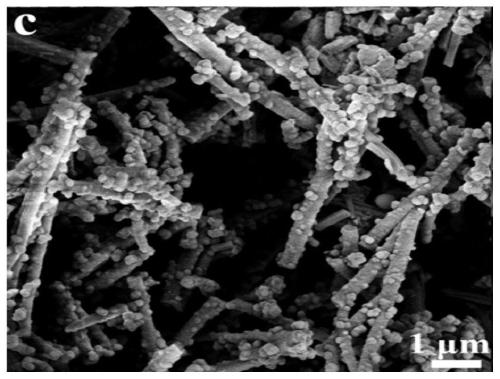

A kind of copper phthalocyanine/γ-bismuth molybdate composite nanofiber photocatalytic material and its preparation method and application

A technology of composite nanofibers and photocatalytic materials, applied in the field of photocatalytic materials, can solve the problems of difficult recycling and reuse, high application cost, unfavorable photo-generated carrier transport and separation, etc., so as to improve photocatalytic efficiency, facilitate transport and Separating and enhancing the effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material includes the following steps:

[0065] (1) Preparation of spinnable precursor sol: Dissolve 1.0 g of citric acid in 8 ml of deionized water at room temperature, and stir until dissolved; then add 0.177 g of ammonium molybdate and 0.970 g of bismuth nitrate pentahydrate to the above To the solution, add 1.6ml of 68% concentrated nitric acid and stir at room temperature for 2h to obtain a clear and transparent solution B; add 3ml of solution B and 1.5ml of 68% concentrated nitric acid to 15ml of absolute ethanol and mix at room temperature The solution D is uniformly obtained; 1.2 g of polyvinylpyrrolidone (PVP, K-90) is dissolved in the above solution D and stirred at room temperature for 15 hours to obtain a spinnable precursor sol.

[0066] (2) Preparation of γ-bismuth molybdate nanofibers: transfer the spinnable precursor sol obtained in step (1) into a 20ml plasti...

Embodiment 2

[0070] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material includes the following steps:

[0071] (1) Preparation of spinnable precursor sol: Dissolve 2.5g of citric acid in 20ml of deionized water at room temperature, and stir until dissolved; then add 0.442g of ammonium molybdate and 2.425g of bismuth nitrate pentahydrate to the above To the solution, add 3ml of concentrated hydrochloric acid with a mass fraction of 37% and stir at room temperature for 1 hour to obtain a clear and transparent solution B. Add 2ml of solution B and 1.0ml of 37% concentrated hydrochloric acid to 10ml of absolute ethanol, mix well at room temperature to obtain solution D; dissolve 0.75g of polyvinylpyrrolidone (PVP, K-90) in the above solution D, After stirring at room temperature for 12 hours, a spinnable precursor sol was obtained.

[0072] (2) Preparation of γ-bismuth molybdate nanofibers: transfer the spinnable precursor sol obtained in s...

Embodiment 3

[0077] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material includes the following steps:

[0078] (1) Preparation of spinnable precursor sol: Dissolve 2g of citric acid in 16ml of deionized water at room temperature and stir until dissolved; then add 0.353g of ammonium molybdate and 1.94g of bismuth nitrate pentahydrate to the above solution Then, add 2ml of concentrated hydrochloric acid with a mass fraction of 37% and stir at room temperature for 4 hours to obtain a clear and transparent solution B. Add 2ml of solution B and 2.0ml of 37% concentrated hydrochloric acid to 8ml of absolute ethanol, mix well at room temperature to obtain solution D; dissolve 1g of polyvinylpyrrolidone (PVP, K-90) in the above solution D at room temperature After 24 hours of stirring, a spinnable precursor sol is obtained.

[0079] (2) Preparation of γ-bismuth molybdate nanofibers: transfer the spinnable precursor sol obtained in step (1) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com