Photosensitive water-developable resistance welding composition and photosensitive water-developable resistance welding dry film

A composition and water development technology, applied in optics, photography, photomechanical equipment, etc., can solve the problem of low adhesion of photosensitive water development solder mask dry film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

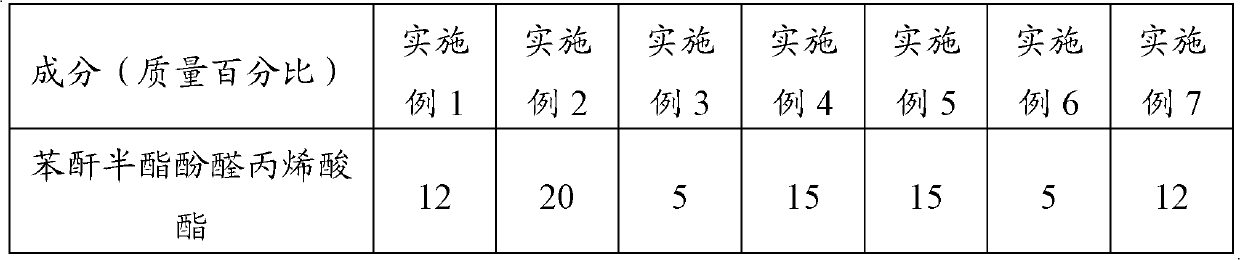

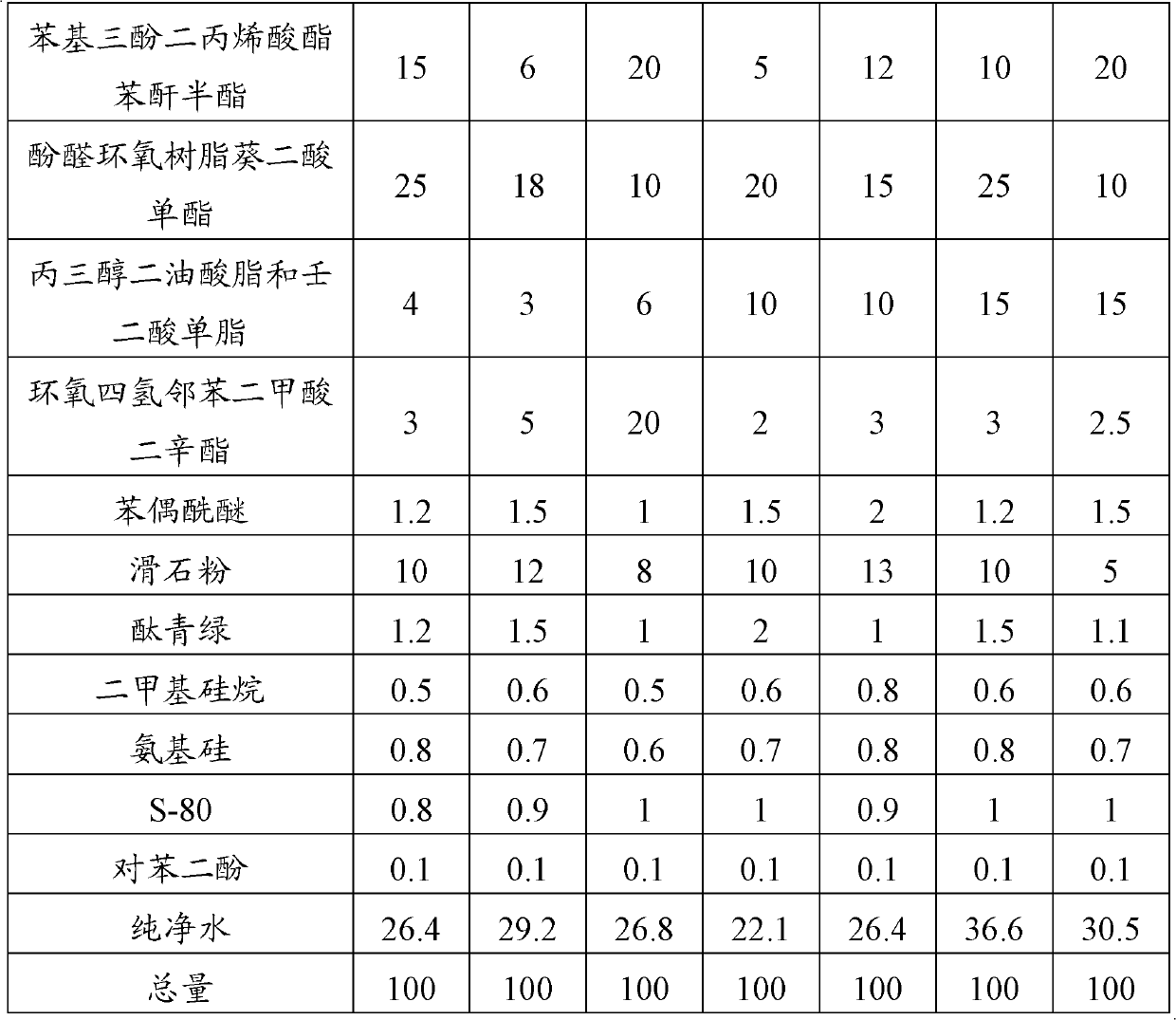

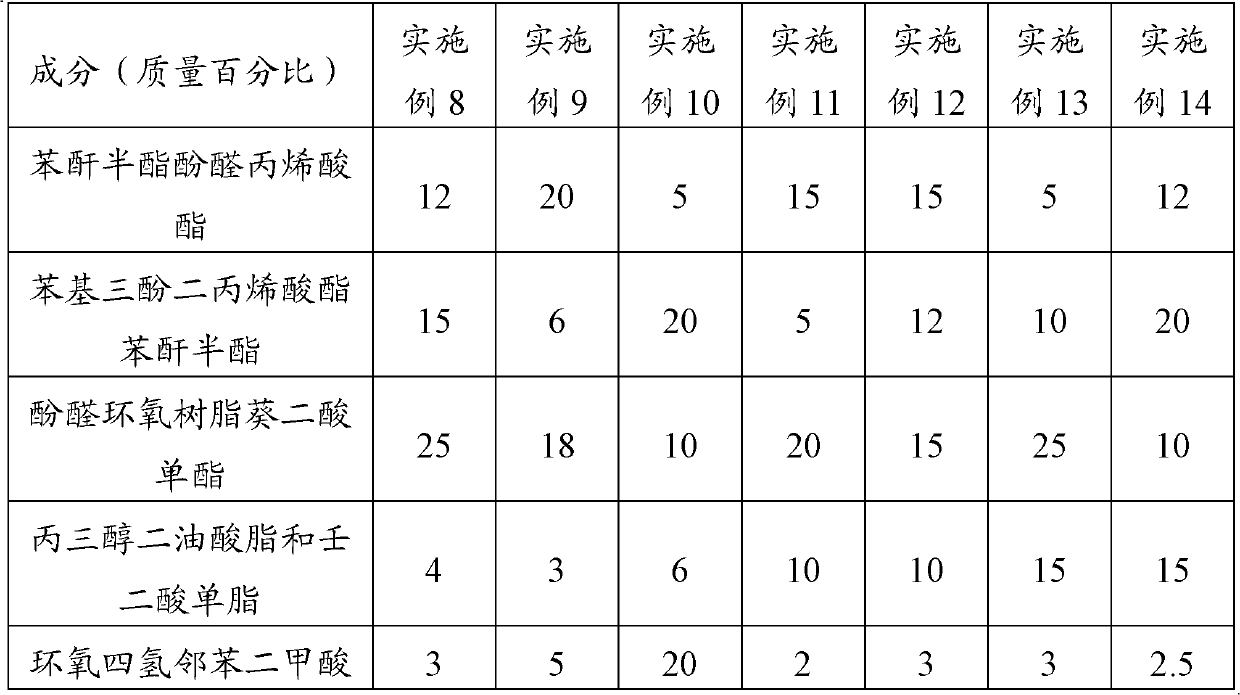

Examples

Embodiment Construction

[0039] In order to solve the problem of insufficient adhesion of traditional solder resist dry films, a photosensitive water-developable solder resist composition with high adhesion and a photosensitive water-developable solder resist dry film composed of the photosensitive water-developable solder resist composition are proposed. The following will be further elaborated through specific embodiments.

[0040] One embodiment of the photosensitive water-developed solder resist composition, which is composed of phthalic anhydride half-ester modified novolak epoxy acrylate, phenyl triphenol diacrylate and phthalic anhydride half-ester, novolak epoxy resin sebacate monoester, photoinitiated agent, colorant, plasticizer, inorganic filler, leveling defoamer, coupling agent, emulsifier, polymerization inhibitor and the rest of water.

[0041] The mass percent of the phthalic anhydride half-ester modified novolac epoxy acrylate is 5-50%, preferably 10-40%.

[0042] Phthalic anhydride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com