Multi-channel DC motor control system based on FPGA and DSP

A DC motor and control system technology, applied in the direction of controlling multiple DC motors, can solve the problems of flexibility, difficult system transplantation, limited control range, etc., achieve a large cost reduction, reduce the number of circuits, and improve the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

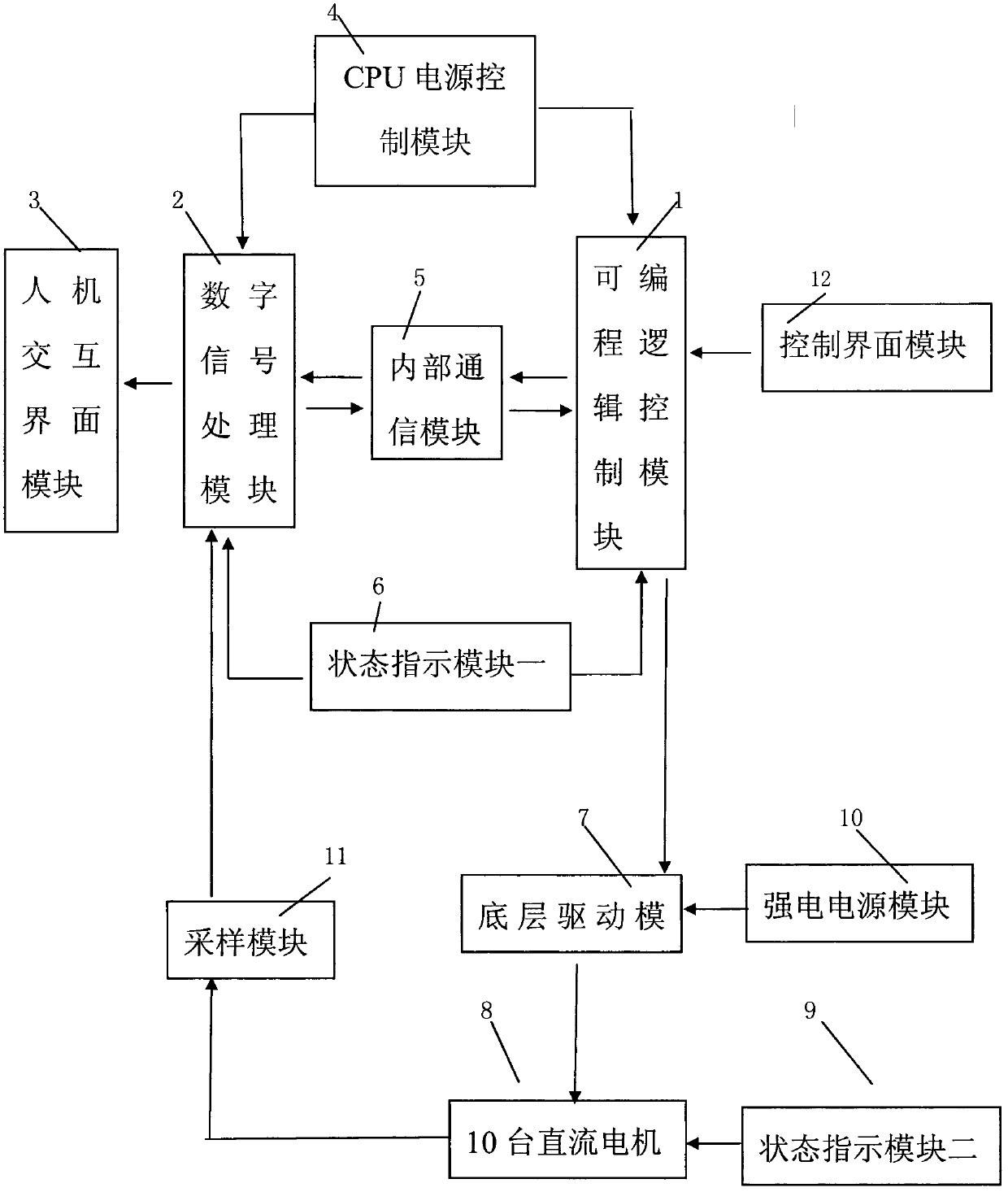

[0020] Embodiment: a kind of multi-channel (10 channels) DC motor control system based on DSP and FPGA, it is characterized in that system is by: main control programmable logic device module 1, digital signal processor module 2, man-machine interface 3, CPU Power supply module 4, internal communication module 5, status indication module 1 6, bottom drive module 7, 10-way DC motor module 8, status indication module 2 9, strong current power supply module 10, sampling module 11, control interface module 12 and other modules .

[0021] The main control programmable logic device module mentioned above uses EP1C6Q240C8N as the main chip. The programmable logic device module is provided with two power supplies by the CPU power supply module, one is a 1.5V core power supply, and the other is a 3.3VI / O power supply. Among the I / O resources of the chip itself, 32 I / O ports are allocated to the control interface module, 20 I / Os are allocated to the underlying driver module, and 45 I / O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com