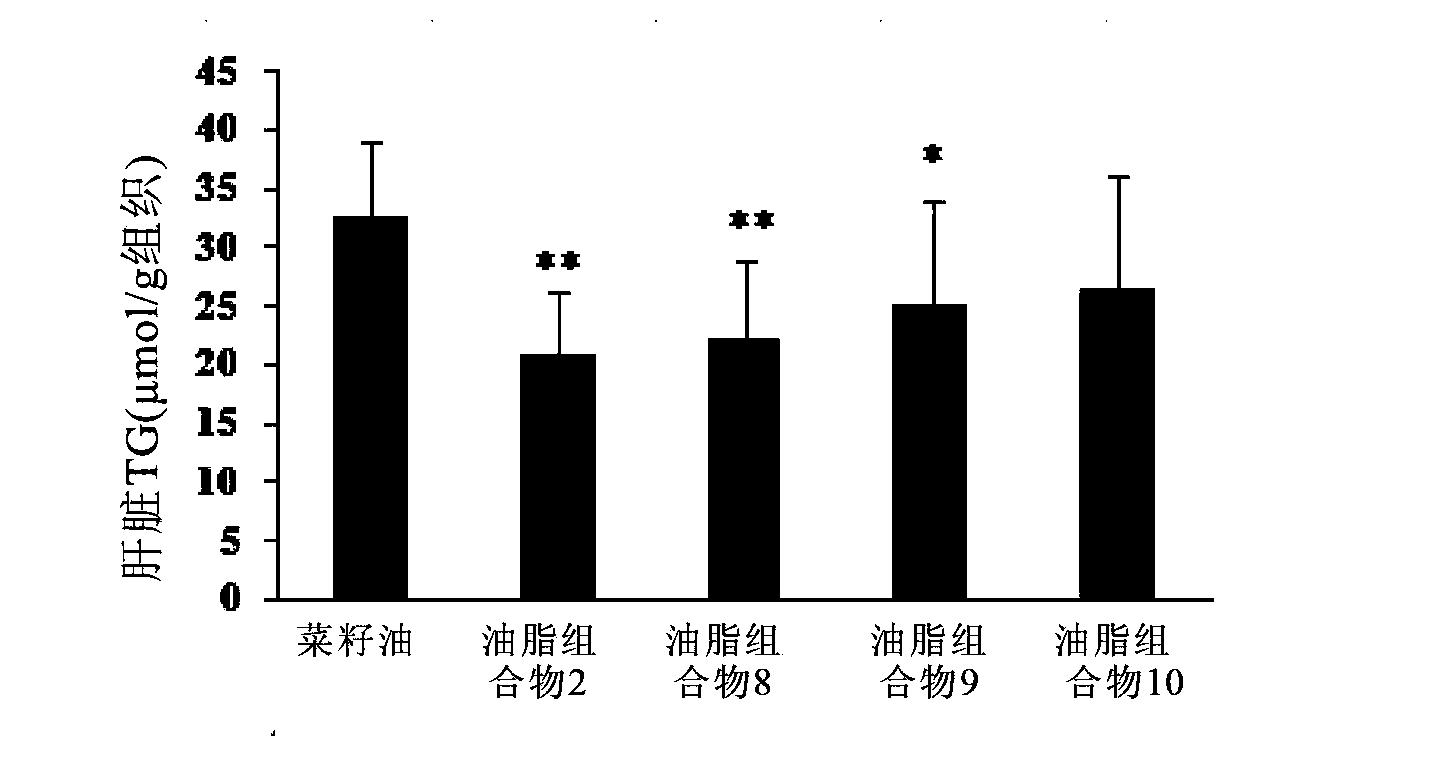

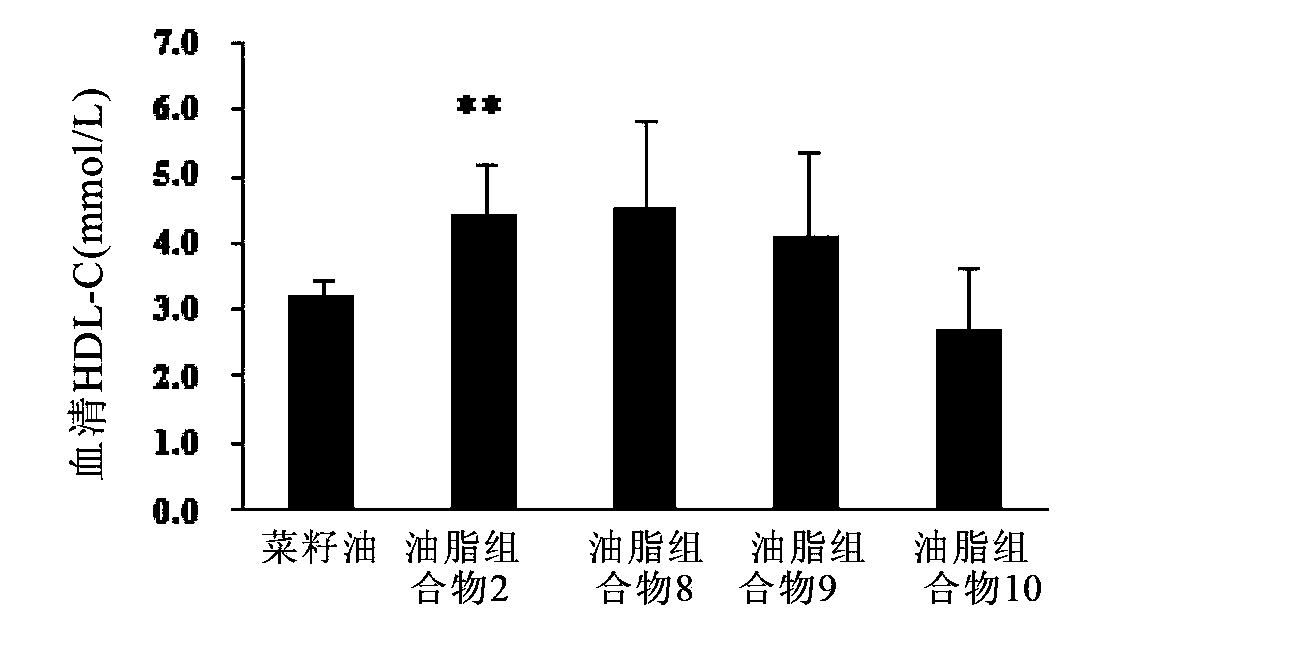

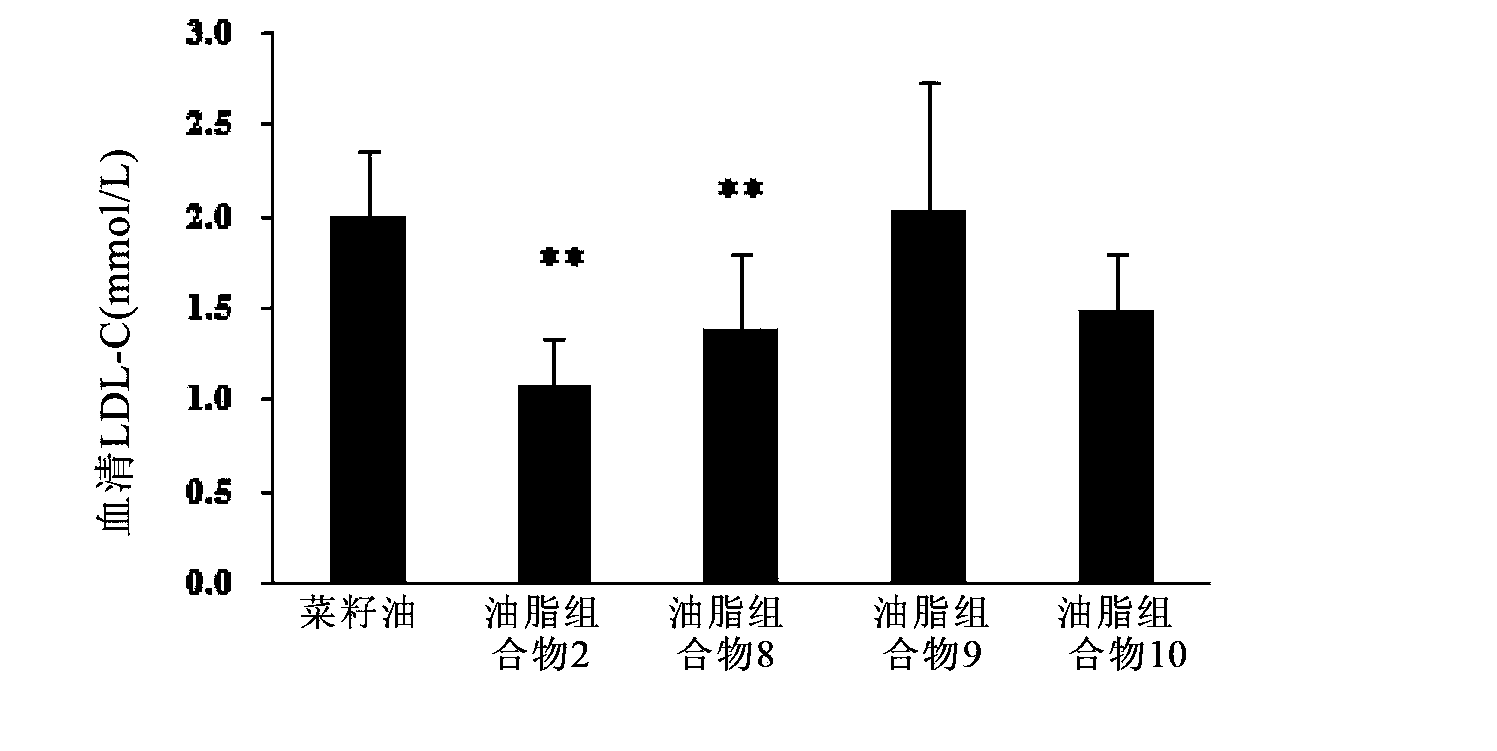

Grease composition for preventing obesity fatty liver and preparation method thereof

A technology of oil composition and oil, which is applied in food preparation, edible oil/fat, animal feed, etc., and can solve problems such as easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Another method for preparing the oil composition of the present invention is a chemical catalytic preparation method. The method comprises: mixing the raw oil and medium-chain triglyceride, adding a catalyst accounting for 0.1-2% by mass of the total weight of the raw material (raw oil + MCT) after vacuum drying, so that the ratio between the raw oil and the medium-chain triglyceride is about 90 React at a temperature of -120°C, add a citric acid solution with a concentration of 6-10% according to the total weight of the raw materials at 8-12% by mass to terminate the reaction, then wash the reaction product with water until the pH is neutral, dry and decolorize, and molecularly distill at 160~230°C , and deodorize to obtain the oil composition of the present invention.

[0059] In the chemical catalysis method, the molar ratio of raw oil and medium chain triglyceride is heterotrophic as defined in the enzymatic method, within the range of 0.25~1.25:1. Technicians can ...

Embodiment 1

[0076] Mix palm olein (produced by Yihai Kerry) and MCT (caprylic acid / capric acid = 60 / 40) in a molar ratio of 0.25:1, then put it into the raw material tank of the enzymatic reactor, and use 0.5 times the amount of enzyme per hour The flow rate was slowly passed through a packed column filled with 2wt% of the total weight of raw materials lipase (Lipozyme RM IM), and the transesterification reaction was carried out at 30°C. The reaction product was molecularly distilled at 160°C, decolorized and deodorized to obtain oil composition 1.

Embodiment 2

[0078] Mix rapeseed oil (produced by Yihai Kerry) and MCT (caprylic acid / capric acid = 60 / 40) in a molar ratio of 0.5:1, and then put it into the raw material tank of the enzymatic reactor, and use 2 times the amount of enzyme per hour The flow rate was slowly passed through the column filled with lipase (Lipozyme TL IM) added with 10wt% of the total weight of raw materials, and the transesterification reaction was carried out at 60°C. The reaction product was molecularly distilled at 190°C, decolorized and deodorized to obtain oil composition 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com