Natural product preparation capable of reducing methane production amount of rumen microorganisms

A technology of rumen microorganisms and natural products, applied in the field of natural product preparations, can solve the problems of chemical substance tolerance residues and limitations in practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Grind Vitex fruit into powder with a traditional Chinese medicine grinder, weigh 0.25g into a 15mL centrifuge tube, and add 5mL of 70% ethanol solution;

[0024] (2) Vortex → 35rpm rotary mixer mixing for 30min → vortex →rotary mixer mixing for 30min (twice total 1h) → 3000r centrifugation for 5min;

[0025] (3) Draw the supernatant to a freezing bottle, and dry it with a nitrogen blower;

[0026] (4) Retain the precipitate in the centrifuge tube, continue to add 5mL 70% ethanol→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min (three times a total of 1.5h)→3000r Centrifuge for 5min;

[0027] (5) Take the supernatant to the blown-dried freezing bottle, blow dry with nitrogen blower, freeze dryer for 24-48 hours, wait until it rises to room temperature, weigh, seal the bottle, and store at -20°C.

Embodiment 2

[0029] (1) Grind Vitex fruit into powder with a traditional Chinese medicine grinder, weigh 0.25g into a 15mL centrifuge tube, and add 5mL of 60% ethanol solution;

[0030] (2) Vortex → 35rpm rotary mixer mixing for 30min → vortex →rotary mixer mixing for 30min (twice total 1h) → 3000r centrifugation for 5min;

[0031] (3) Draw the supernatant to a freezing bottle, and dry it with a nitrogen blower;

[0032] (4) Precipitate remains in the centrifuge tube, continue to add 5mL 60% ethanol→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min (three times a total of 1.5h)→3000r Centrifuge for 5min;

[0033] (5) Take the supernatant to the blown-dried freezing bottle, blow dry with nitrogen blower, freeze dryer for 24-48 hours, wait until it rises to room temperature, weigh, seal the bottle, and store at -20°C.

Embodiment 3

[0035] (1) Grind Vitex fruit into powder with a traditional Chinese medicine grinder, weigh 0.25g into a 15mL centrifuge tube, and add 5mL of 80% ethanol solution;

[0036] (2) Vortex → 35rpm rotary mixer mixing for 30min → vortex →rotary mixer mixing for 30min (twice total 1h) → 3000r centrifugation for 5min;

[0037] (3) Draw the supernatant to a freezing bottle, and dry it with a nitrogen blower;

[0038] (4) Keep the precipitate in the centrifuge tube, continue to add 5mL 80% ethanol→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min→vortex shaker→rotate mixer for 30min (three times a total of 1.5h)→3000r Centrifuge for 5min;

[0039] (5) Take the supernatant to the blown-dried freezing bottle, blow dry with nitrogen blower, freeze dryer for 24-48 hours, wait until it rises to room temperature, weigh, seal the bottle, and store at -20°C.

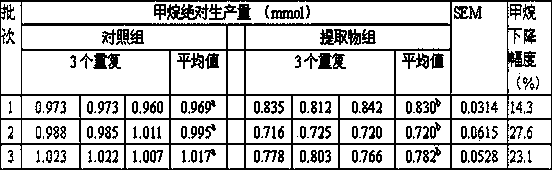

[0040] Combined with the in vitro fermentation test in the rumen, the extent to which the preparation reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com