Manufacture method of ridge type Y-branch optical waveguide structure

A manufacturing method and optical waveguide technology, which are applied in the direction of light guides, optics, optical components, etc., can solve the problems of etching the bifurcated side walls of incomplete Y-shaped substrates, unexpected propagation loss, etc., to reduce signal loss and improve optical waveguide structure The effect of smoothness and good light guiding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Please refer to Figure 1-7 , a method for fabricating a ridge-shaped Y-branch optical waveguide structure 100 according to an embodiment of the present invention, which includes steps S1-S6.

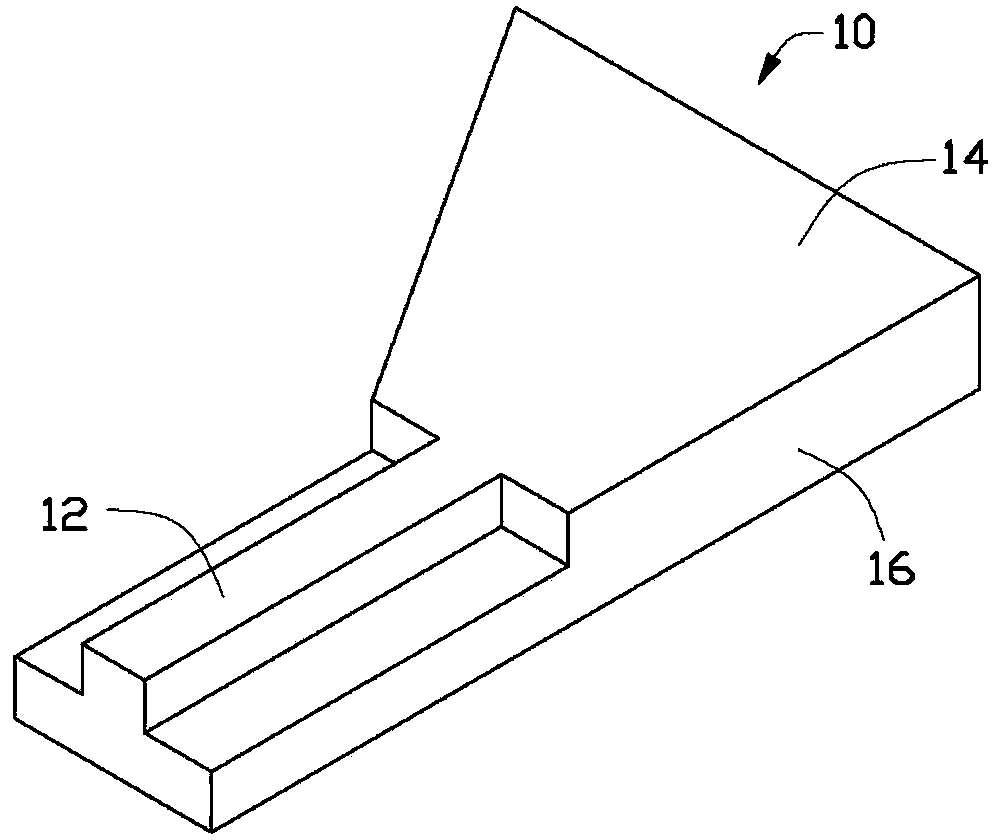

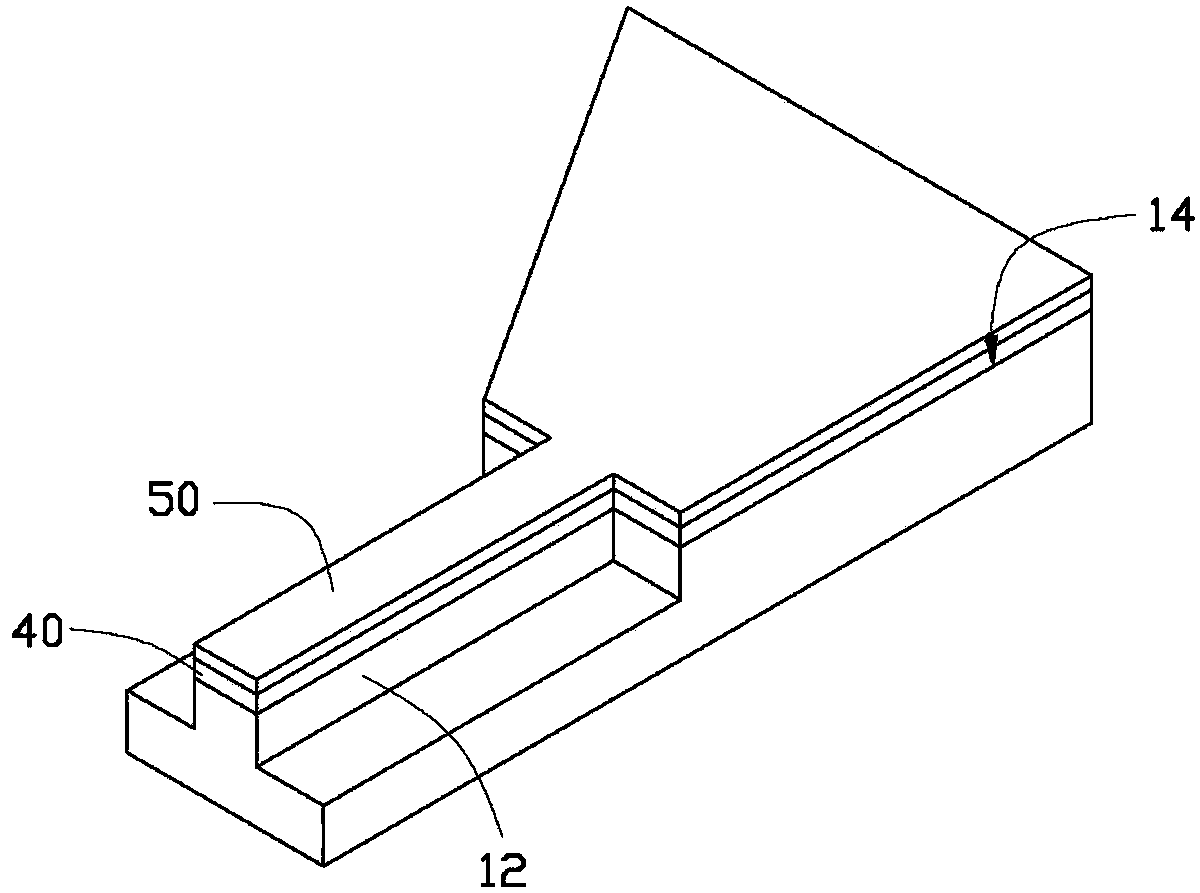

[0013] Step S1: provide a substrate 10, please refer to figure 2 , the substrate 10 includes a T-shaped ridge 12 and a flat portion 16 connected to the ridge 12 , and the flat portion 16 includes a bearing plane 14 .

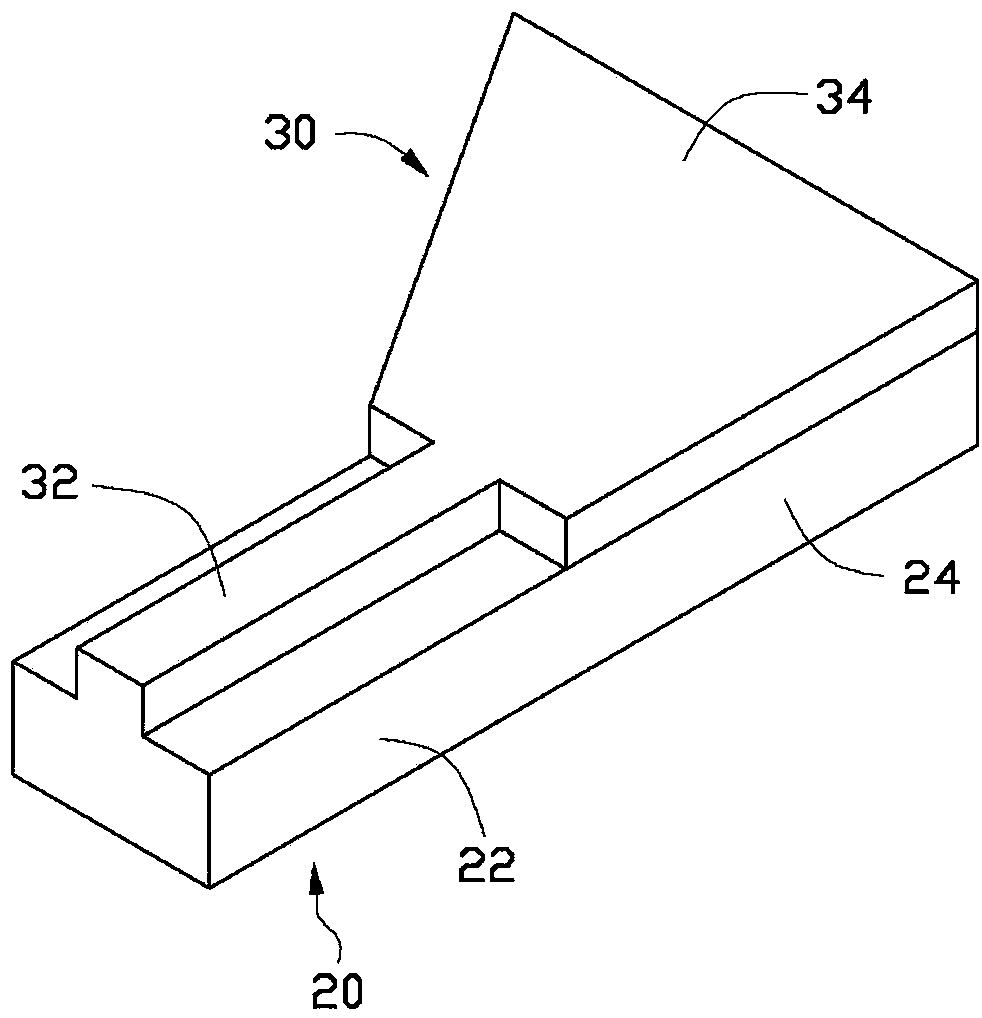

[0014] Wherein, the step of making substrate 10 is: as figure 1 As shown, a flat bottom plate 20 is provided, and the material of the flat bottom plate 20 is lithium niobate or barium niobate. The flat bottom plate 20 includes a first flat plate portion 22 and a second flat plate portion 24 connected to the first flat plate portion 22, and an etching mask 30 is formed on the flat bottom plate 20 by an exposure and development method, wherein the The material of etching mask 30 is chromium or silicon dioxide, and this etching mask 30 comprises strip-shaped porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com