Anti-inflammatory drug for postpartum sow and preparation method thereof

A technology for breeding sows and drugs, applied in the field of drugs, can solve the problems of wasting feed, failing to achieve postpartum anti-inflammatory lochia discharge, and increasing breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

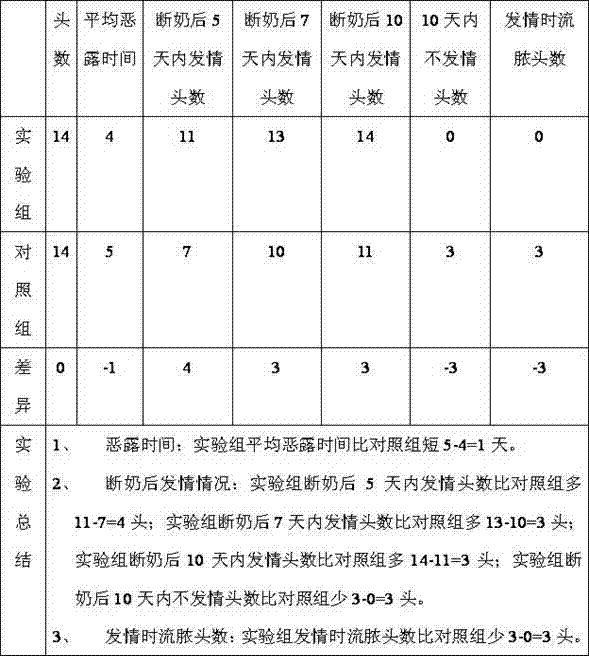

Examples

Embodiment 1

[0023] First 10% of Naproxen and 30% of Metronidazole are pulverized and sieved to make it reach 100 mesh fineness, and then the above-mentioned pulverized 10% of Naproxen, 30% of Metronidazole and 2.0% of Gentamicin sulfate, 1.2% metoclopramide, 17.6% motherwort, 27.38% pottery clay, and 10% Daditian were poured into the wet granulator and rotated forward for 10 minutes, reversed for 10 minutes, and mixed evenly. Then add the prepared 1.82% starch, stir for 8 minutes, and finally put the stirred material into the swing granulator to granulate, and the granulated medicine is sent to the fluidized bed for drying through the negative pressure tube, and the drying temperature is 75 ℃, the drying time is 120 minutes, so that the water content of the granules is lower than 2%, and the dried medicine is sorted through a 18-60 mesh sieve, and packed.

[0024] The starch 1.82% is formulated into 5% starch slurry, and the steps are as follows: first, stir the starch evenly with 20% col...

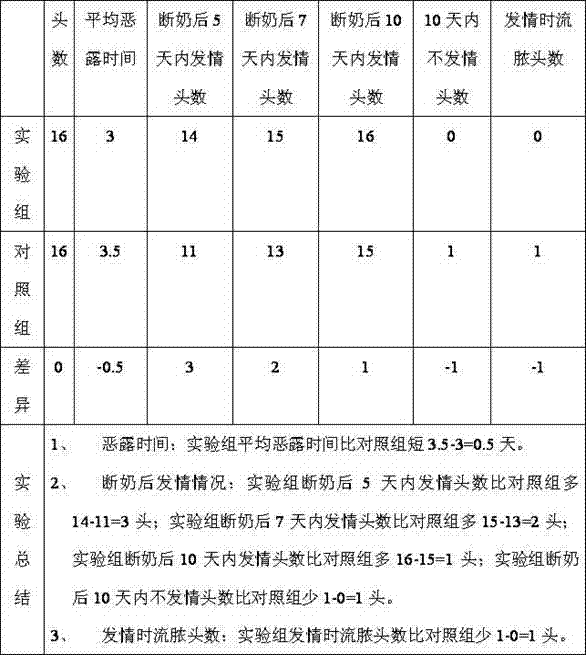

Embodiment 2

[0026] First 9% Naproxen and 28% Metronidazole are pulverized and sieved to make it reach 100 mesh fineness, then the above-mentioned pulverized 9% Naproxen, 28% Metronidazole and 1.8% Gentamicin sulfate, 1.4% metoclopramide, 17.8% motherwort, 27.40% pottery clay, and 11% Daditian were poured into the wet granulator and rotated forward for 10 minutes, reversed for 10 minutes, and mixed evenly. Then add the prepared 1.84% starch, stir for 8 minutes, and finally put the stirred material into the swing granulator to granulate, and the granulated medicine is sent to the fluidized bed for drying through the negative pressure tube, and the drying temperature is 75 ℃, the drying time is 120 minutes, so that the water content of the granules is lower than 2%, and the dried medicine is sorted through a 18-60 mesh sieve, and packed.

[0027] The starch 1.84% is formulated into 5% starch slurry, and the steps are as follows: first, stir the starch evenly with 20% cold water, then add the...

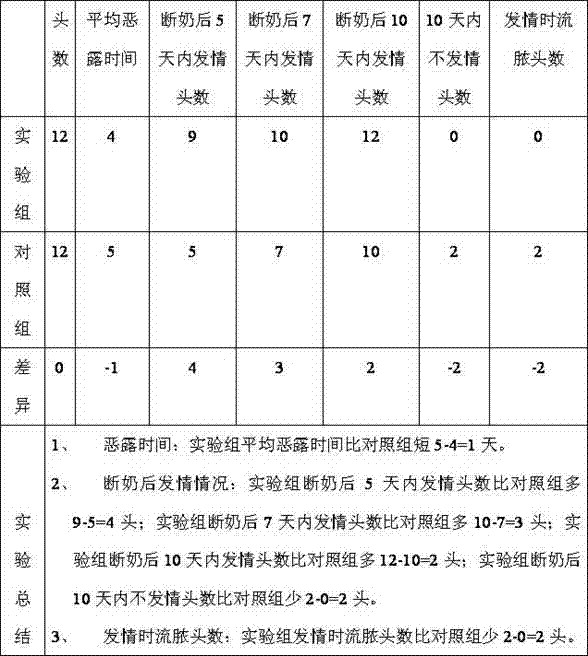

Embodiment 3

[0029] First 11% Naproxen and 32% Metronidazole are pulverized and sieved to make it reach 100 mesh fineness, then the above-mentioned pulverized 11% Naproxen, 32% Metronidazole and 2.2% Gentamicin sulfate, 1.0% metoclopramide, 17.4% motherwort, 27.36% pottery clay, and 9% Daditian were poured into the wet granulator and rotated forward for 10 minutes, reversed for 10 minutes, and mixed evenly. Then add the prepared 1.80% starch, stir for 8 minutes, and finally put the stirred material into the swing granulator to granulate, and the granulated medicine is sent to the fluidized bed for drying through the negative pressure tube, and the drying temperature is 80 ℃, the drying time is 120 minutes, so that the water content of the granules is lower than 2%, and the dried medicine is sorted through a 18-60 mesh sieve, and packed.

[0030] The starch 1.80% is formulated into 5% starch slurry, and the steps are as follows: first, stir the starch evenly with 20% cold water, then add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com