Process for extracting curcumin through ultrasonic-aqueous two-phase synergy

A curcumin and two-phase technology, applied in the field of plant pigment extraction research, can solve the problems of severe reaction conditions, large environmental pollution, high price, etc., and achieve the effects of simple extraction process, reduced environmental pollution, and improved extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking 10g of raw turmeric as an example, the ultrasonic-two-phase synergistic extraction process is used to extract curcumin in turmeric, which is realized by the following steps:

[0021] (1) take by weighing 10g turmeric, add 200mL excessive sherwood oil after pulverizing with FZ102 type plant pulverizer and be used for deoiling, obtain the turmeric filter cake after degreasing;

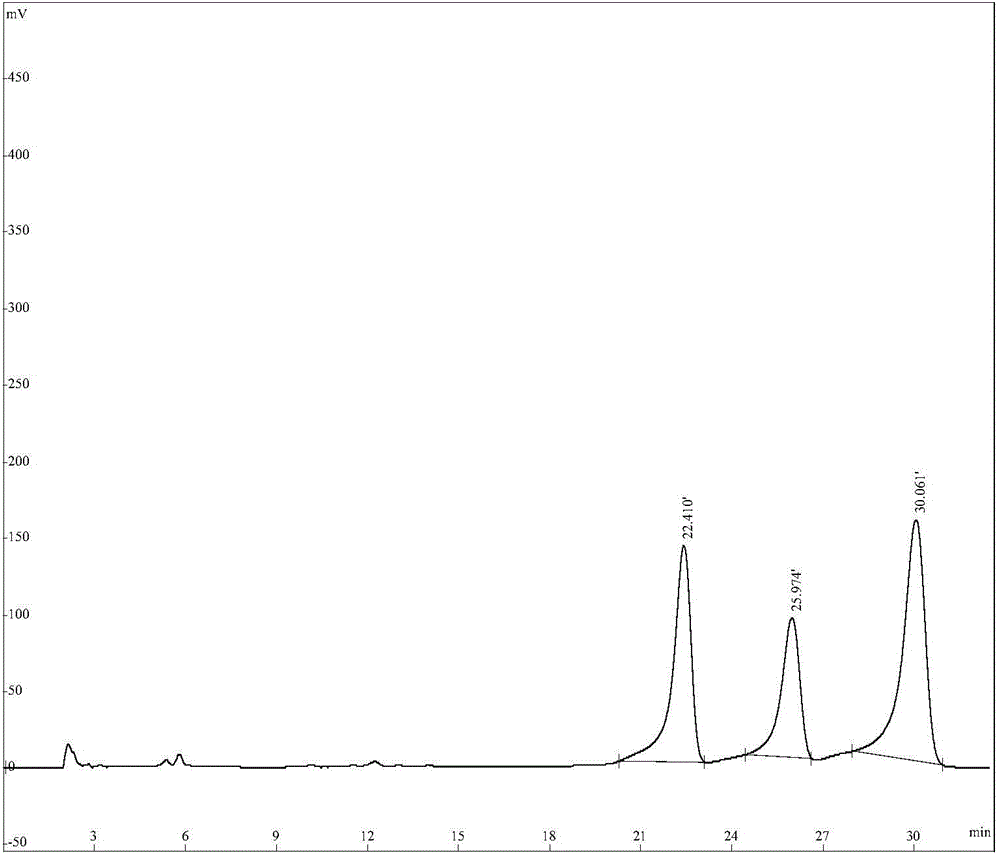

[0022] (2) The turmeric filter cake is placed in 100mL concentration of 75% ethanol, the solid-liquid ratio is 1:10, the ultrasonic time is 18min, and the ultrasonic power density is 2.3W / cm 2 , under the condition that the ultrasonic frequency is 23kHz, and the ultrasonic radiation mode is 7s / 10s, the curcumin is extracted by ultrasonic, and the extract is obtained by ultrasonic 4 times;

[0023] (3) the ammonium sulfate of 60g is dissolved in 100mL water, obtains ammonium sulfate aqueous solution, in step (2) gained extract, add the ammonium sulfate aqueous solution of equivalent, make th...

Embodiment 2

[0029] Taking 10g of raw turmeric as an example, the ultrasonic-two-phase synergistic extraction process is used to extract curcumin in turmeric, which is realized by the following steps:

[0030] (1) take by weighing 10g turmeric, add excessive sherwood oil after pulverizing with pulverizer and be used for deoiling, obtain the turmeric filter cake after degreasing;

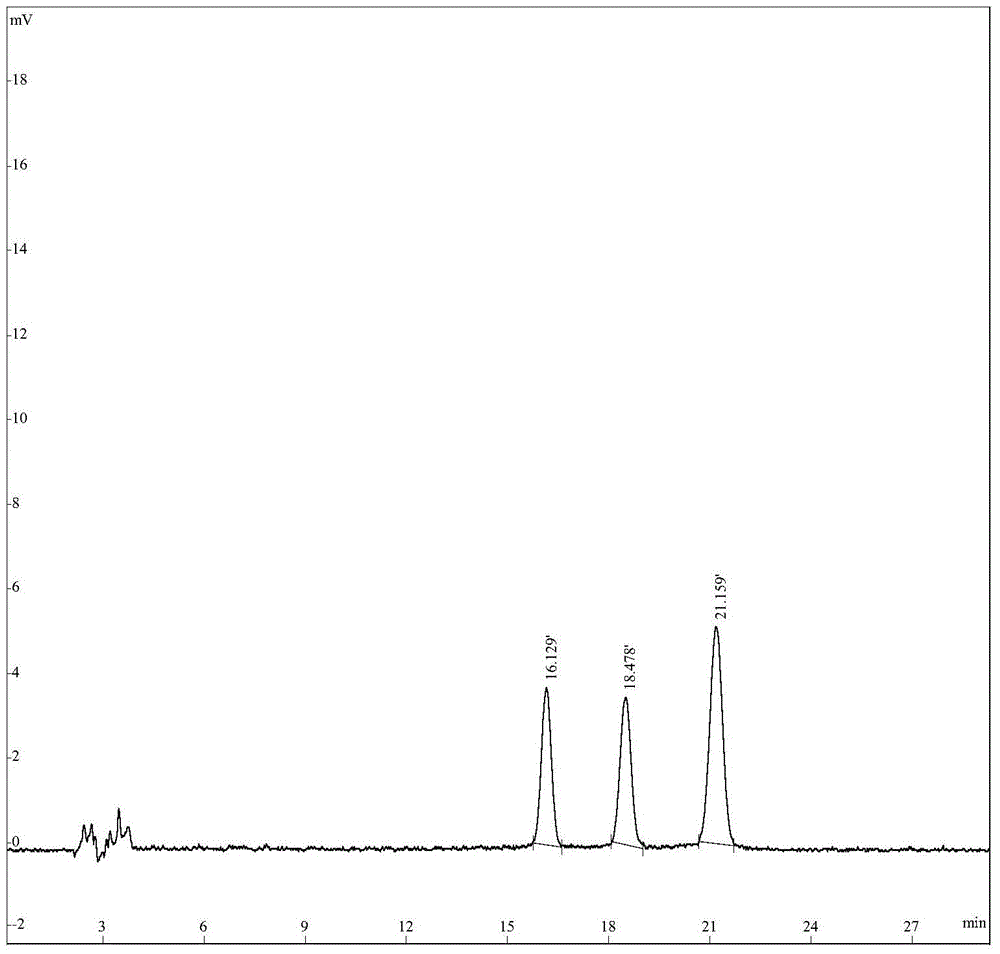

[0031] (2) The turmeric filter cake is placed in 75% ethanol, the solid-liquid ratio is 1:9, the ultrasonic time is 15min, and the ultrasonic power density is 2.2W / cm 2 , under the condition that the ultrasonic frequency is 20kHz, and the ultrasonic radiation mode is 6s / 10s, the curcumin is extracted by ultrasonic, and the extract is obtained by ultrasonic 3 times;

[0032] (3) the ammonium sulfate of 58g is dissolved in 100mL water, obtains ammonium sulfate aqueous solution, in step (2) gained extract, add the ammonium sulfate aqueous solution of equivalent, make the volume ratio of extract liquid and ammonium s...

Embodiment 3

[0035] Taking 10g of raw turmeric as an example, the ultrasonic-two-phase synergistic extraction process is used to extract curcumin in turmeric, which is realized by the following steps:

[0036] (1) take by weighing 10g turmeric, add excessive sherwood oil after pulverizing with pulverizer and be used for deoiling, obtain the turmeric filter cake after degreasing;

[0037] (2) The turmeric filter cake is placed in 75% ethanol, the solid-liquid ratio is 1:11, the ultrasonic time is 15min, and the ultrasonic power density is 2.2W / cm 2 , under the condition that the ultrasonic frequency is 20kHz, and the ultrasonic radiation mode is 6s / 10s, the curcumin is extracted by ultrasonic, and the extract is obtained by ultrasonic 3 times;

[0038] (3) the ammonium sulfate of 61g is dissolved in 100mL water, obtains the ammonium sulfate aqueous solution, adds the equivalent ammonium sulfate aqueous solution in step (2) gained extract, makes the volume ratio of extract and ammonium sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com