Nanometer fuel oil catalytic additive

A nano-catalyst and additive technology, which is applied in the direction of fuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of dispersion of nano-fuel catalytic additives, environmental pollution, etc., to repair engine damage and gaps, prevent fuel combustion rate, enhance gas tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

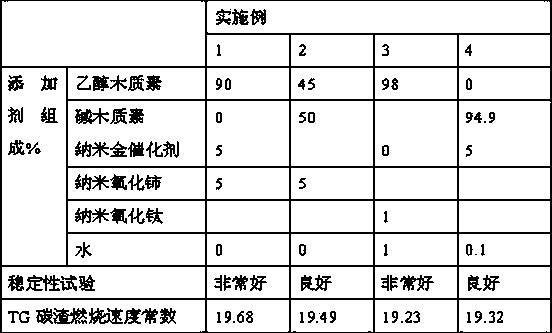

Embodiment 1-4

[0096] The test method for the stability test of granular nano-fuel catalytic additives is as follows:

[0097] While stirring at 20 °C and 60 rpm, the nano-fuel catalytic additive was prepared, and the dissolution rate until the lignin was completely dissolved in the A-grade heavy oil was evaluated by measuring the number of seconds. The stability of the solution obtained after standing at room temperature for one week was evaluated.

[0098] "Very good" means completely dissolved,

[0099] "Good" means almost dissolved,

[0100] "Qualified" means that a small amount of insoluble matter can be observed,

[0101] "Not good" means that very much insoluble material was observed.

[0102] The test results are shown in the table below

[0103]

[0104] The nano-fuel catalytic additive components of the above-mentioned Examples 1-4 were extruded into granules through a screw. Add 1g of nano fuel catalytic additive (ie 0.5%) to 200g of diesel. Test the TG carbon slag burnin...

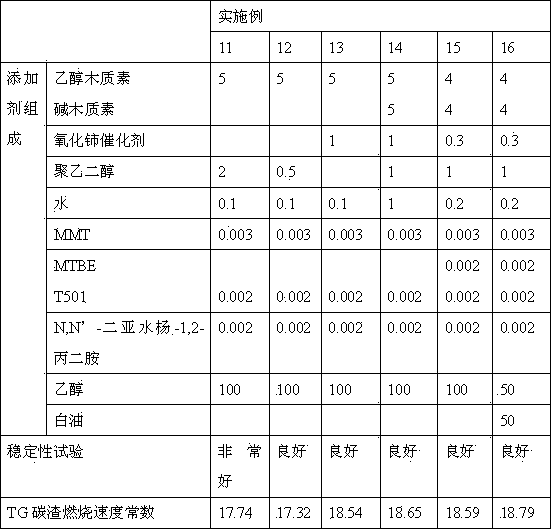

Embodiment 5-10

[0106] The test method for the stability test of liquid nano-fuel catalytic additives is as follows:

[0107] While stirring at 20°C and 60rpm, the nano-fuel catalytic additive was prepared by the composition shown in the table below, and the dissolution rate until the lignin was completely dissolved in the A-grade heavy oil was evaluated by measuring the number of seconds. The stability of the solution obtained after standing at room temperature for one week was evaluated.

[0108] "Very good" means completely dissolved,

[0109] "Good" means almost dissolved,

[0110] "Qualified" means that a small amount of insoluble matter can be observed,

[0111] "Not good" means that very much insoluble material was observed.

[0112] The test results are shown in the table below.

[0113]

[0114]

[0115] After the above components are uniformly dispersed in the dispersant, 0.2g of nano fuel catalytic additive (ie 0.1%) is added to 200g of diesel. Test the TG carbon slag burnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com