Lithium ion battery formation sectional charging method

A lithium-ion battery, segmented charging technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc. Looseness and other problems, to achieve the effect of improving chemical charging efficiency, good cycle performance, and reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

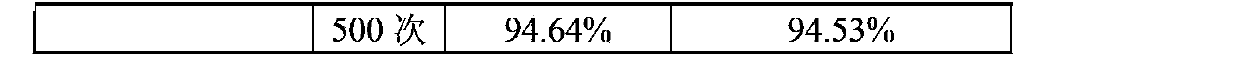

Embodiment 1

[0014] A lithium-ion power battery with lithium iron phosphate as the cathode material system with a capacity of 16.5Ah was used to form a charging process under stable room temperature conditions.

[0015] 1. Stand still: 5min

[0016] 2. Constant current charging stage 1: charging current: 0.15C, charging time: 100min;

[0017] 3. Stand still: 2min;

[0018] 4. Constant current charging stage 2: charging current: 0.5C, charging cut-off voltage: 3.57V;

[0019] 5. Stand still: 5min;

[0020] 6. Constant current charging stage three: charging current: 0.15C, charging cut-off voltage: 4.2V;

[0021] 7. Constant voltage charging stage: charging voltage: 4.2V, charging cut-off current: 0.03C;

[0022] 8. Standing: 10min.

[0023] After the completion of the formation stage, it was left at room temperature for 7 days and then charged and discharged.

Embodiment 2

[0031] The lithium-ion power battery with lithium iron phosphate as the positive electrode material system has a capacity of 20 Ah, controlling the stable room temperature conditions for the battery formation and charging process.

[0032] 1. Stand still: 10min

[0033] 2. Constant current charging stage 1: charging current: 0.1C, charging time: 180min;

[0034] 3. Stand still: 2min;

[0035] 4. Constant current charging stage 2: charging current: 0.3C, charging cut-off voltage: 4.0V;

[0036] 5. Stand still: 20min;

[0037] 6. Constant current charging stage three: charging current: 0.1C, charging cut-off voltage: 4.2V;

[0038] 7. Constant voltage charging stage: charging voltage: 4.2V, charging cut-off current: 0.01C;

[0039] 8. Standing: 20min.

[0040] After the completion of the formation stage, it was left at room temperature for 7 days and then charged and discharged.

Embodiment 3

[0048] The lithium-ion power battery with lithium iron phosphate as the positive electrode material system has a capacity of 130 Ah, controlling the stable room temperature conditions for the battery formation and charging process.

[0049] 1. Stand still: 5min

[0050] 2. Constant current charging stage 1: charging current: 0.3C, charging time: 40min;

[0051] 3. Stand still: 10min;

[0052] 4. Constant current charging stage 2: charging current: 0.6C, charging cut-off voltage: 3.5V;

[0053] 5. Stand still: 5min;

[0054] 6. Constant current charging stage three: charging current: 0.3C, charging cut-off voltage: 4.2V;

[0055] 7. Constant voltage charging stage: charging voltage: 4.2V, charging cut-off current: 0.05C;

[0056] 8. Standing: 20min.

[0057] After the completion of the formation stage, it was left at room temperature for 7 days and then charged and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com