Manufacturing equipment and production process and method of biaxial orientation PVC (Poly Vinyl Chloride) and polyolefin material pipe

A technology of biaxial orientation and manufacturing equipment, applied in the direction of tubular objects, other household utensils, household utensils, etc., can solve the problems of low toughness and strength, poor high temperature resistance, long cycle time, etc., and achieve strength and toughness Effects of improvement, increase in strength and toughness, and increase in production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

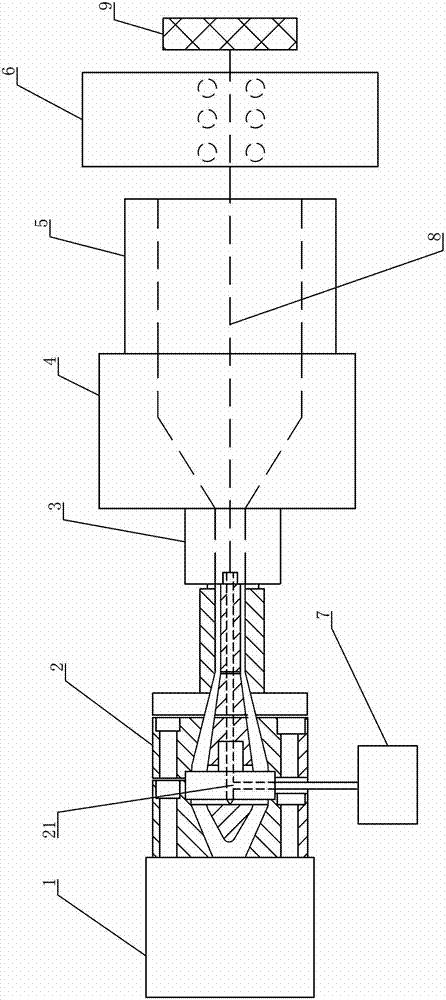

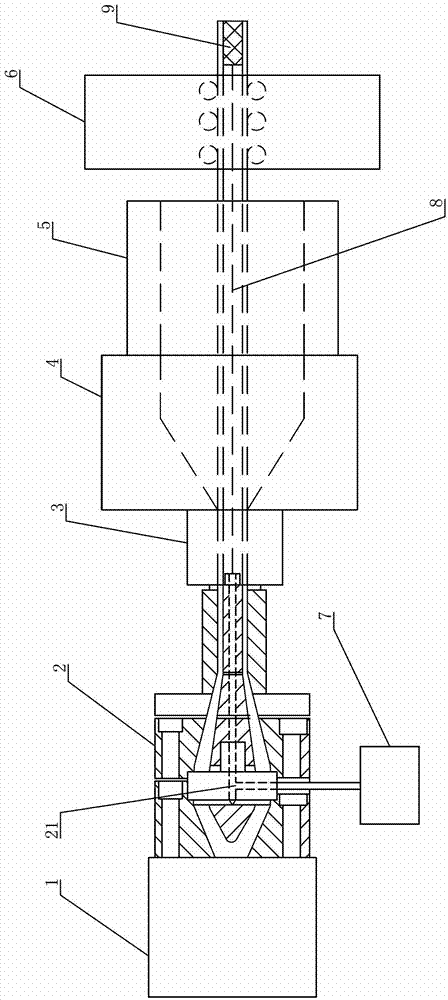

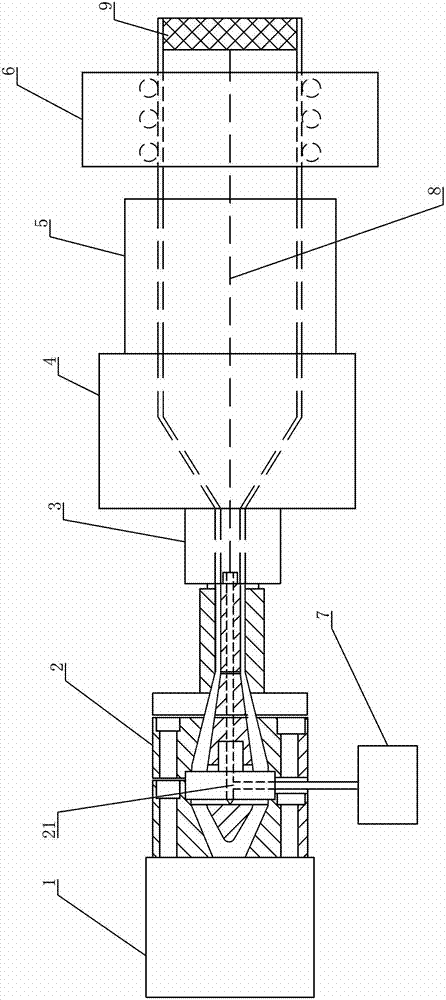

[0027] To make a biaxially oriented pipe with an outer diameter of 75 mm and a thickness of 1.9 mm made of PVC, the production process is as follows:

[0028] 1): Pre-start the extruder 1, send the prefabricated pipe to the tractor 6 and clamp it;

[0029] 2): Pass the drawstring 8 at the outlet end of the pipe forming die 2 through the pipe, and block the inside of the pipe with an elastic plug 9;

[0030] 3): Start the compressor 7, the extruder 1 and the tractor 6, and the pipe is conveyed forward at a speed of 2.8m / min. At this time, ensure that the inside of the pipe is under a positive pressure of 0.1MPa;

[0031] 4): When the pipe passes through the expansion temperature adjustment zone 3, reduce the temperature of the pipe to 120°C;

[0032] 5): When the pipe passes through the expansion and sizing area 4, the diameter of the pipe is expanded and stretched according to the shape of the pipe in the expansion and sizing area 4 under the action of air pressure, and the e...

Embodiment 2

[0036] To make a biaxially oriented pipe with an outer diameter of 50mm, a thickness of 4.6mm, and a material of PP, the production process is as follows:

[0037] 1): Pre-start the extruder 1, send the prefabricated pipe to the tractor 6 and clamp it;

[0038] 2): Pass the drawstring 8 at the outlet end of the pipe forming die 2 through the pipe, and block the inside of the pipe with an elastic plug 9;

[0039] 3): Start the compressor 7, the extruder 1 and the tractor 6, and the pipe is conveyed forward at a speed of 2.2m / min. At this time, ensure that the inside of the pipe is under a positive pressure of 0.3MPa;

[0040] 4): When the pipe passes through the expansion temperature adjustment zone 3, reduce the temperature of the pipe to 150°C;

[0041] 5): When the pipe passes through the expansion and sizing area 4, the diameter of the pipe is expanded and stretched according to the shape of the pipe in the expansion and sizing area 4 under the action of air pressure, and...

Embodiment 3

[0045] To make a biaxially oriented pipe with an outer diameter of 160mm, a thickness of 6.0mm, and a material of PE, the production process is as follows:

[0046] 1): Pre-start the extruder 1, send the prefabricated pipe to the tractor 6 and clamp it;

[0047] 2): Pass the drawstring 8 at the outlet end of the pipe forming die 2 through the pipe, and block the inside of the pipe with an elastic plug 9;

[0048] 3): Start the compressor 7, the extruder 1 and the tractor 6, and the pipe is conveyed forward at a speed of 1.6m / min. At this time, ensure that the inside of the pipe is under a positive pressure of 0.5MPa;

[0049] 4): When the pipe passes through the expansion temperature adjustment zone 3, reduce the temperature of the pipe to 150°C;

[0050] 5): When the pipe passes through the expansion and sizing area 4, the diameter of the pipe is expanded and stretched according to the shape of the pipe in the expansion and sizing area 4 under the action of air pressure, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com