Artificial wetland composite matrix for nitrogen and phosphorus removal of rural sewage and preparation method thereof

A technology for artificial wetlands, nitrogen and phosphorus removal, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of enhancing the water flow capacity, enhancing the removal efficiency, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

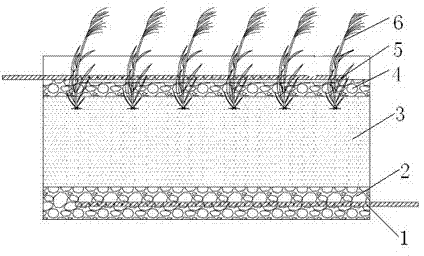

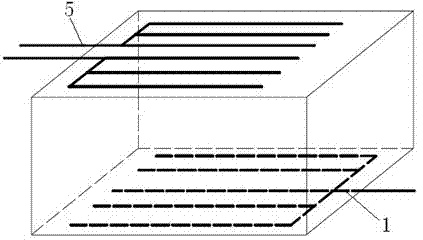

[0024] Pass the gravel through a 4mm sieve, and then pass the gravel with a particle size greater than 4mm through an 8mm sieve, so that the particle size of the gravel is controlled within 4-8mm, rinse the 4-8mm gravel with tap water, and air dry for later use; coarse sand, Sawdust, titanium-making waste slag, steel-making blast furnace slag, and steel slag are spread on the concrete floor and air-dried respectively; the air-dried titanium-making waste slag is lightly tapped with a hammer to pass through a 2cm sieve to obtain titanium-making waste slag particles with a particle size of less than 2cm for future use. After all materials are air-dried, take by weighing 50kg of coarse sand, 30kg of gravel with a particle size of 4-8mm, 4kg of sawdust, 10kg of titanium-making waste slag particles with a particle size of less than 2cm, 3kg of steelmaking blast furnace slag, and 3kg of steel slag and mix evenly to prepare Adult constructed wetland combination substrate.

[0025] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com