Nanometer bismuth oxide-coated modified boron fuel and preparation methods thereof

A nano-bismuth oxide and modification technology, which is applied in the direction of explosives, can solve the problems of refractory melting and gasification, low combustion efficiency of boron, high melting point and boiling point, and achieve stable combustion state, high combustion efficiency and good fuel performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

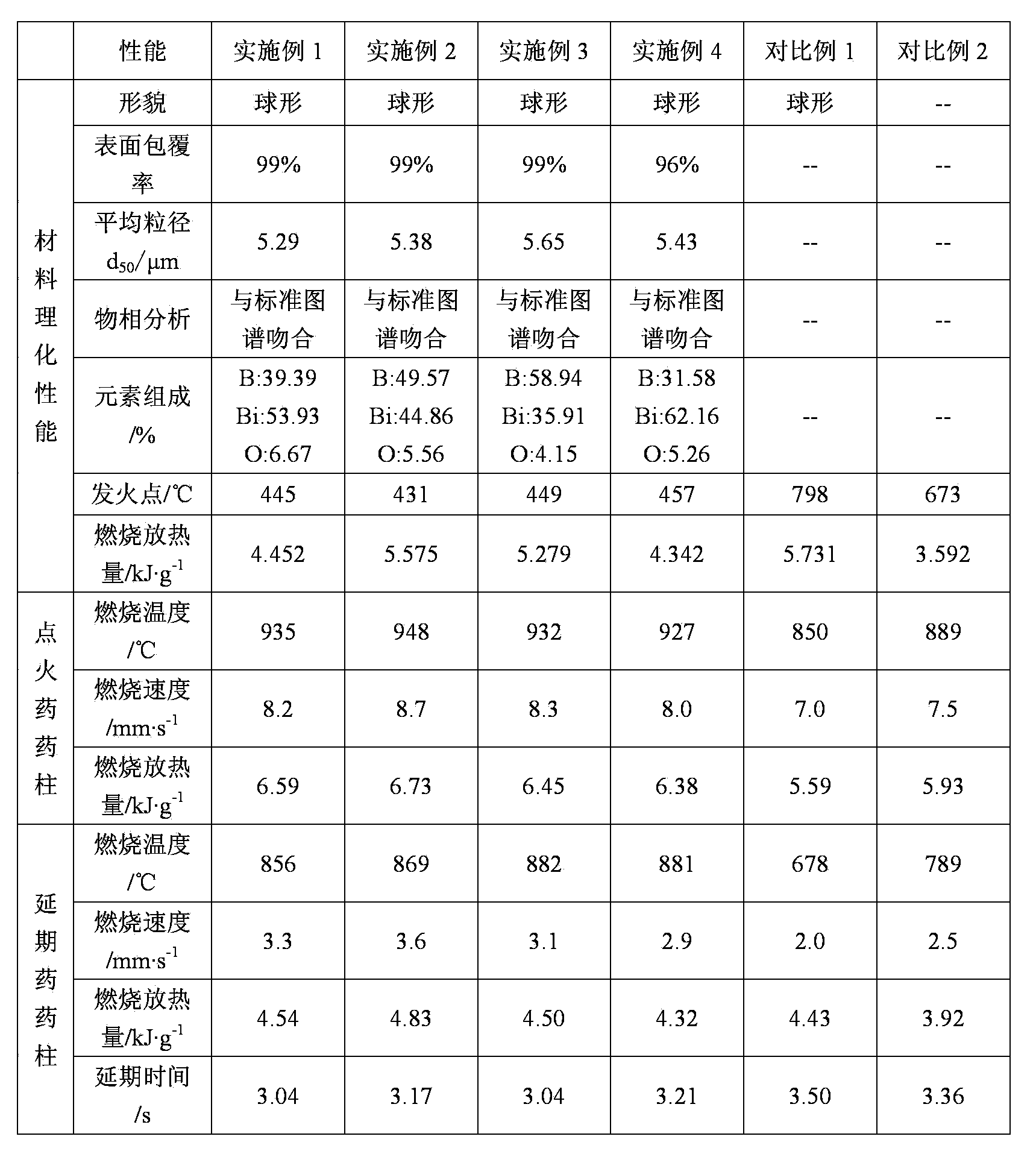

[0053] Example 1 Modified boron fuel prepared by precipitation method

[0054] Taking the target product mass of 1.553g (the mass ratio of boron to bismuth oxide is 40:60) as an example, the amount of various raw materials required is: bismuth nitrate pentahydrate 1.94g, sodium hydroxide 0.68g, ultrafine boron powder 0.621 g (the average particle size is 4.9 μm), ethanol 200ml. Accurately weigh quantitative bismuth nitrate pentahydrate and sodium hydroxide, and dissolve them in ethanol respectively; under normal temperature and stirring conditions, add ultrafine boron powder to the bismuth nitrate solution, and fully stir to make it evenly dispersed in the solution; Add sodium hydroxide solution dropwise to the mixed suspension to make it fully react, filter the product, wash with deionized water and ethanol three times respectively, vacuum dry at 60°C for 2h, and calcinate at 400°C for 2h, the obtained product is The nano-bismuth oxide-coated modified boron fuel of this pate...

Embodiment 2

[0056] Example 2 Modified boron fuel prepared by precipitation method

[0057] Taking the target product mass of 1.864g (the mass ratio of boron to bismuth oxide is 50:50) as an example, the amount of various raw materials required is: bismuth nitrate pentahydrate 1.94g, sodium hydroxide 0.68g, ultrafine boron powder 0.932 g (average particle size is 5.07μm), ethanol 200ml. Accurately weigh quantitative bismuth nitrate pentahydrate and sodium hydroxide, and dissolve them in ethanol respectively; under normal temperature and stirring conditions, add ultrafine boron powder to the bismuth nitrate solution, and fully stir to make it evenly dispersed in the solution; Add sodium hydroxide solution dropwise to the mixed suspension to make it fully react, filter the product, wash with deionized water and ethanol three times respectively, vacuum dry at 60°C for 2h, and calcinate at 400°C for 2h, the obtained product is The nano-bismuth oxide-coated modified boron fuel of this patent; ...

Embodiment 3

[0059] Example 3 Modified boron fuel prepared by precipitation method

[0060] Taking the target product mass of 2.332g (the mass ratio of boron to bismuth oxide is 60:40) as an example, the amount of various raw materials required is: 1.94g of bismuth nitrate pentahydrate, 0.68g of sodium hydroxide, and 1.4g of superfine boron powder g (average particle size is 5.3μm), ethanol 200ml. Accurately weigh quantitative bismuth nitrate pentahydrate and sodium hydroxide, and dissolve them in ethanol respectively; under normal temperature and stirring conditions, add ultrafine boron powder to the bismuth nitrate solution, and fully stir to make it evenly dispersed in the solution; Add sodium hydroxide solution dropwise to the mixed suspension to make it fully react, filter the product, wash with deionized water and ethanol three times respectively, vacuum dry at 60°C for 2h, and calcinate at 400°C for 2h, the obtained product is The nano-bismuth oxide-coated modified boron fuel of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com