Steel plate for plastic mold for rolling continuous casting slab with thickness of 400mm and production method of steel plate

A technology for plastic molds and continuous casting billets, applied in the field of mold steel, can solve the problems of poor flaw detection performance and uneven hardness distribution, and achieve the effects of low production cost, uniform hardness distribution, and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

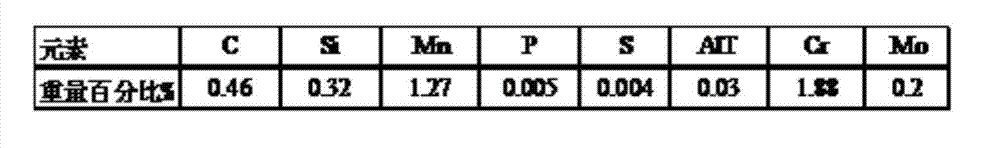

[0021] This implementation example is a production process of using a 400mm thick continuous casting slab to produce a 60mm steel plate for plastic molds. The flaw detection performance of the steel plate meets the requirements of GB / T 2970 Class I, and its composition weight percentage is shown in Table 1:

[0022] Table 1 Chemical composition, the balance is Fe

[0023]

[0024] The production process is carried out according to the following procedures:

[0025] (1) Using molten iron pretreatment and converter smelting, after LF furnace refining and RH vacuum treatment, through continuous casting with a 400mm large-section casting machine into an ultra-thick continuous casting slab;

[0026] (2) After the continuous casting slab is treated with pile cooling, it is sent to the heating furnace for heating at 460°C. The heating temperature is 1190°C, and the heating time is 3.5h;

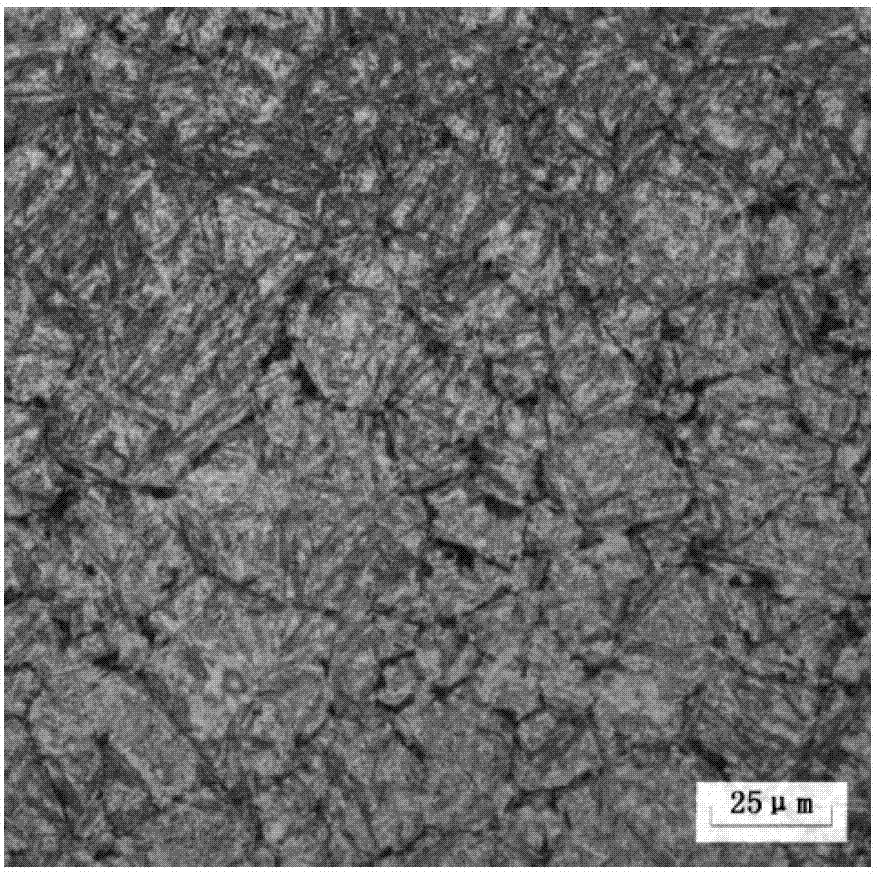

[0027] (3) One-stage controlled rolling with a reduction rate of 22%-30% in a single pass, a...

Embodiment 2

[0030] This implementation example is the production process of using 400mm thick continuous casting slabs to produce 100mm steel plates for plastic molds. The flaw detection performance of steel plates meets the requirements of GB / T 2970 Class I, and its composition weight percentages are shown in Table 1:

[0031] Table 2 Chemical composition, the balance is Fe

[0032]

[0033] The production process is carried out according to the following procedures:

[0034] (1) Using molten iron pretreatment and converter smelting, after LF furnace refining and RH vacuum treatment, through continuous casting with a 400mm large-section casting machine into an ultra-thick continuous casting slab;

[0035] (2) The continuous casting slab is treated by stacking and cooling, and sent to the heating furnace for heating at 480°C. The heating temperature is 1190°C, and the heating time is 3.5h;

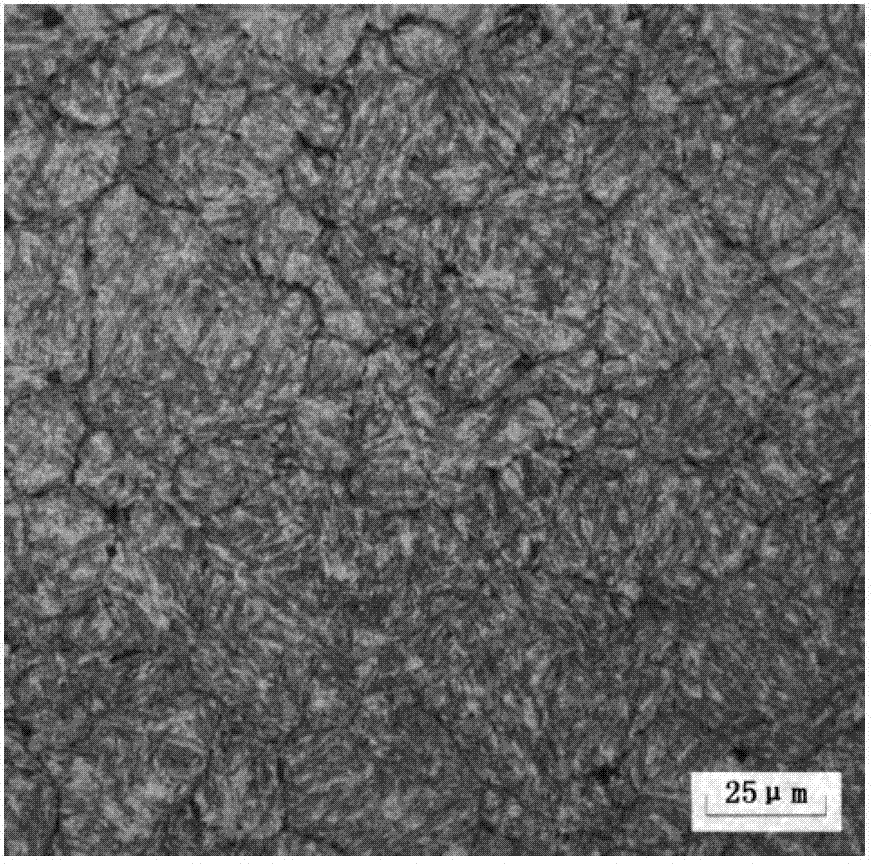

[0036] (3) One-stage controlled rolling with a single pass of 21%-27% large reduction ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com